Corrosion inhibitor used for oil field water, preparation method and detection method

A corrosion inhibitor and oilfield technology, applied in chemical instruments and methods, imino compound preparation, earthwork drilling and production, etc., can solve the problems of poor high temperature resistance, high price, increased dosage, etc., and achieve low cost and short reaction time Short, strong corrosion inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1, corrosion inhibitor for oilfield produced water

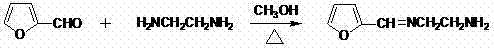

[0038] The corrosion inhibitor includes a main agent and a compounding agent, and the main agent is a Schiff base synthesized from an aromatic aldehyde shown in formula a or formula b and ethylenediamine,

[0039] .

[0040] The compounding agent is urotropine, OP-10 (alkylphenol polyoxyethylene ether), potassium iodide, thiourea or sodium tungstate, and the Schiff base formed by aromatic aldehyde and ethylenediamine is mixed with urotropine according to the mass ratio , OP-10 (alkylphenol polyoxyethylene ether), potassium iodide, thiourea or sodium tungstate, etc., to obtain a finished corrosion inhibitor. The mass ratio of the main agent and urotropine is 1.0:0.04; the mass ratio of the main agent to OP-10 is 1.0:0.05; the mass ratio of the main agent to potassium iodide is 1.0:0.1~0.2; the mass ratio of the main agent to thiourea Ratio 1.0:0.2~0.3; mass ratio of main agent to sodium tungstate 1.0:0....

Embodiment 2

[0045] Add 13.2g of cinnamaldehyde and 2.0g of ethylenediamine to a 250mL three-necked flask equipped with a thermometer, a reflux condenser, and a magnetic rotor, then add 60mL of ethanol, stir and react at 70°C for two hours, and cool the obtained reaction solution Set, obtain precipitation, suction filtration, filter cake is washed with water to obtain yellow solid, is the product main agent a, and its reaction equation is as follows:

[0046]

Embodiment 3

[0047] Embodiment 3, composite

[0048] The mass ratio of main agent a and urotropine is 1.0:0.04; the mass ratio of main agent and OP-10 is 1.0:0.05; the mass ratio of main agent and potassium iodide is 1.0:0.1~0.2; the main agent and thiourea The mass ratio of the main agent to sodium tungstate is 1.0:0.2~0.3; the mass ratio of the main agent to sodium tungstate is 1.0:0.02 and other compounding agents are mixed evenly to obtain the finished corrosion inhibitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com