Three-dimensional nitrogen-doped graphene composite material as well as preparation method and application thereof

A technology of nitrogen-doped graphene and composite materials, applied in the field of electrochemical biosensing, can solve the problems of complex structure of electrode materials, large specific surface area of graphene, easy agglomeration of graphene, etc., and achieve fast and large electron transfer rate. Effect of specific surface area and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

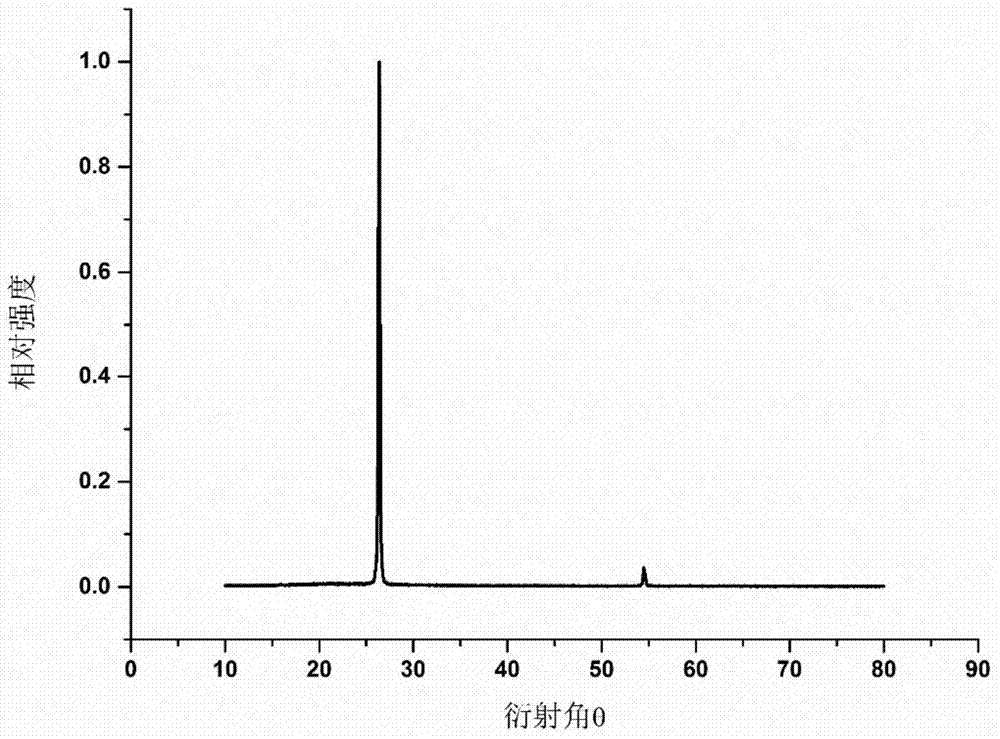

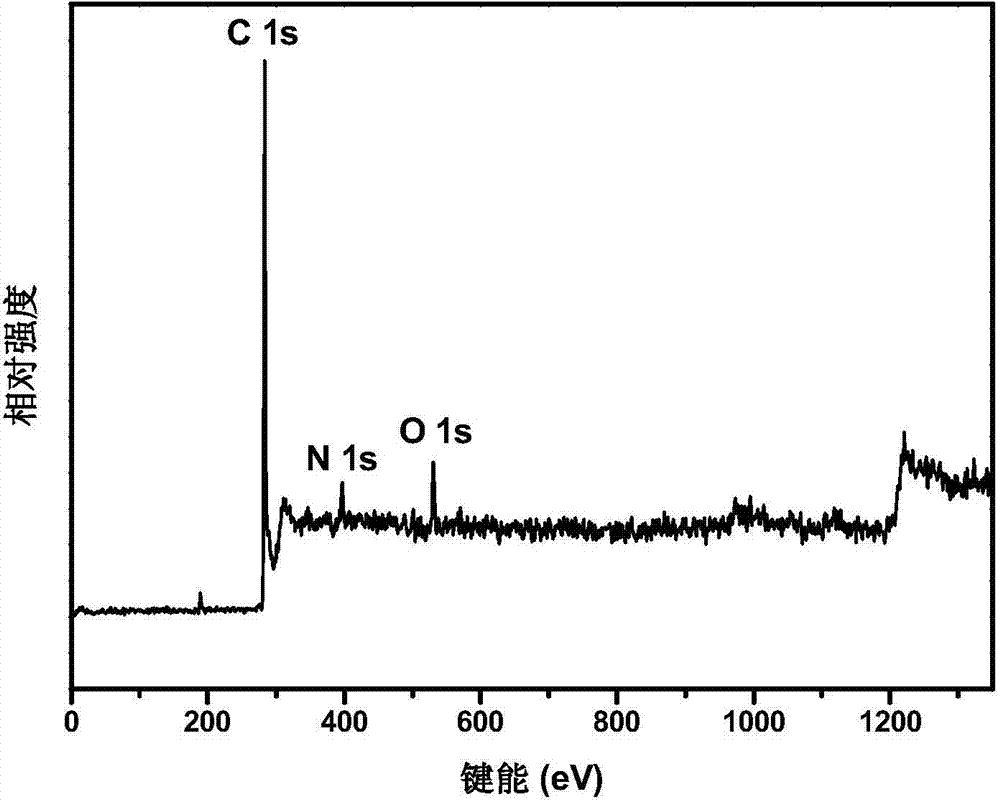

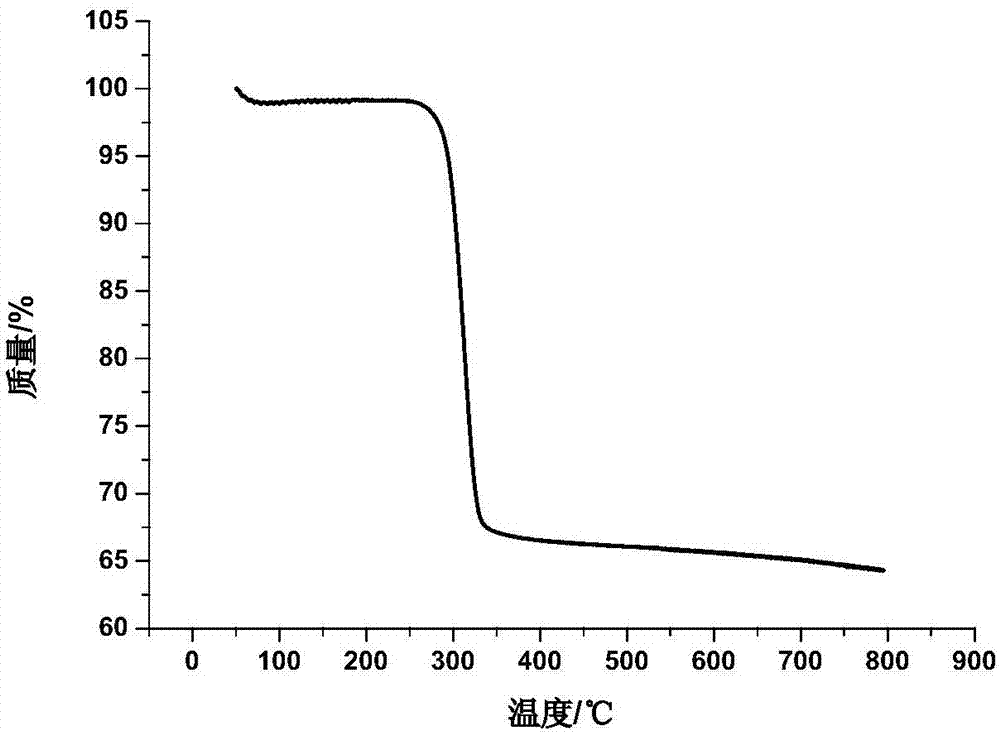

[0032] (1) With nickel foam as the substrate, in hydrogen (flow rate of 20sccm) and argon (flow rate of 20sccm), the substrate is heated from room temperature to 900°C for 10 minutes in a tube furnace, then annealed at a constant temperature for 1 minute, and then closed Hydrogen gas is fed into carbon source methane (flow rate of 1 sccm) and nitrogen source ammonia gas (flow rate of 1 sccm) to stay for 1 min for growth. The volume ratio of methane and ammonia gas is 1:1, and the temperature is lowered to room temperature for 1 min to obtain substrate-containing Three-dimensional nitrogen-doped graphene;

[0033] (2) Transfer the three-dimensional nitrogen-doped graphene obtained in step (1) to 0.1mol / L FeCl 3 After etching for 48 hours, transfer it to a glass Petri dish filled with ultrapure water and soak for a total of 6 times, the first two times for 5 minutes each, and the last four times for 5 minutes each time to obtain three-dimensional nitrogen-doped graphene;

[003...

Embodiment 2

[0037] (1) With nickel foam as the substrate, in hydrogen (flow rate of 200sccm) and argon (flow rate of 400sccm), in a tube furnace, heat the substrate from room temperature to 1000°C for 30 minutes, then anneal at a constant temperature for 5 minutes, and then close Hydrogen gas, feed carbon source methane (flow rate is 10 sccm) and nitrogen source ammonia gas (flow rate is 14 sccm) and stay for 4 minutes to grow, the volume ratio of methane and ammonia gas is 5:7, cool down to room temperature for 25 minutes, and obtain substrate-containing Three-dimensional nitrogen-doped graphene;

[0038] (2) Transfer the three-dimensional nitrogen-doped graphene obtained in step (1) to 1mol / L FeCl 3 Etched for 13 hours, then transferred to a glass petri dish filled with ultrapure water for immersion, a total of 6 times, 20 minutes each time for the first two times, and 8 minutes each time for the last four times, the three-dimensional nitrogen-doped graphene was obtained;

[0039] (3) ...

Embodiment 3

[0045] (1) With nickel foam as the substrate, in hydrogen (flow rate of 1000sccm) and argon (flow rate of 1000sccm), the substrate is heated from room temperature to 1500°C for 60 minutes in a tube furnace and then annealed at a constant temperature for 5 minutes. Hydrogen gas, carbon source methane (flow rate of 100 sccm) and nitrogen source ammonia gas (flow rate of 200 sccm) were introduced to grow for 25 minutes, the volume ratio of methane and ammonia gas was 1:2, and the temperature was lowered to room temperature for 30 minutes to obtain substrate-containing Three-dimensional nitrogen-doped graphene;

[0046] (2) Transfer the three-dimensional nitrogen-doped graphene obtained in step (1) to the nitric acid of 1:5 (analytical pure nitric acid: ultrapure water) for etching for 6 hours, and then transfer to glass culture filled with ultrapure water Soak in a dish for a total of 6 times, the first two times for 60 minutes each time, and the last four times for 30 minutes ea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com