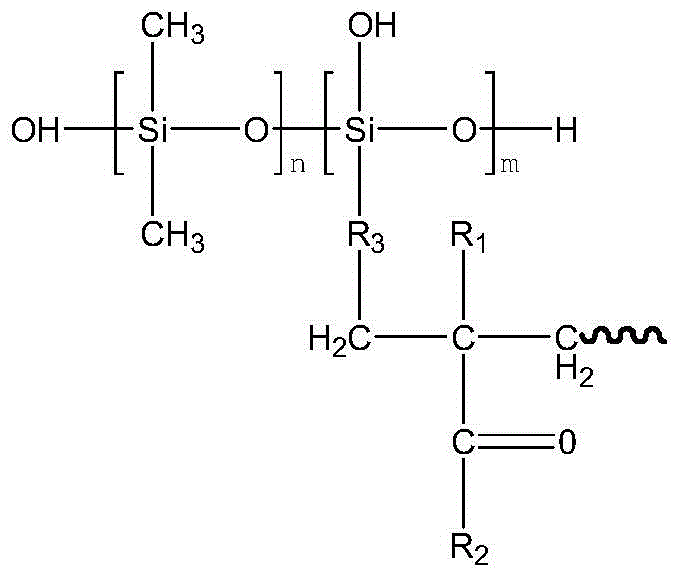

A kind of core-shell structure emulsion deepening agent for polyester fabric and preparation method thereof

A core-shell structure and polyester fabric technology is applied in the field of core-shell structure emulsion deepening agent and its preparation, which can solve the problems of cumbersome operation process, small molecular weight of organosilsesquioxane, limitation and the like, save textile resources, avoid Shade yellowing, to avoid the effect of hard feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

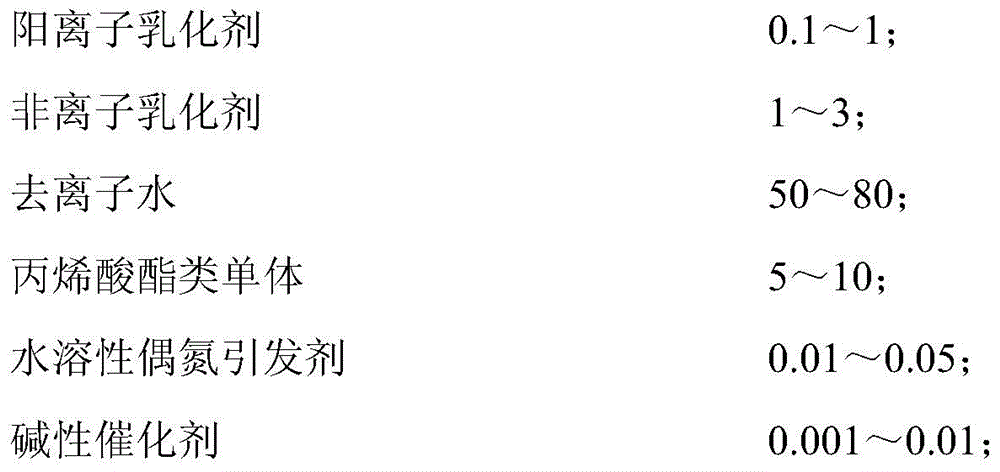

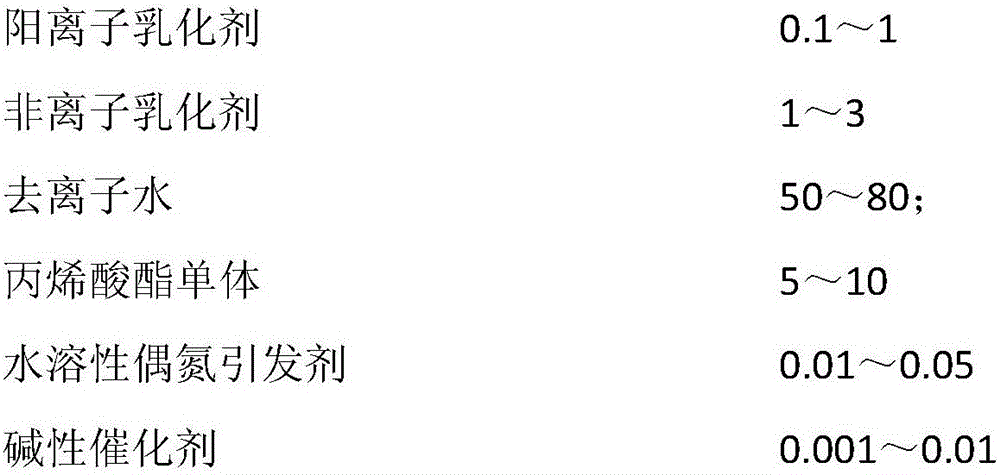

[0037] The preparation of core-shell structure emulsion deepening agent comprises steps:

[0038]Add 0.25g of dodecyldimethylbenzyl ammonium chloride into the reactor, then add 0.25g of fatty alcohol polyoxyethylene ether (AE0-3) and 25g of deionized water, heat and stir, and control the temperature to 45°C , after it was completely dissolved, 6 g of methyl methacrylate monomer was slowly added into the reactor, and the stirring was continued at a stirring speed of 1000 revolutions per minute, and the stirring time was 35 minutes.

[0039] 2) Reduce the stirring speed to 200 rpm, adjust the reaction temperature to 75°C, and add 10 mL of 0.1% azobisisobutylamidine hydrochloride aqueous solution with a certain concentration prepared in advance to the above reactor drop by drop , control the dropping time for 2 hours. After all the drops are completed, a transparent liquid with blue light is obtained. Cool down to 70°C, add 0.3mL of a pre-prepared 1mol / L tetramethylammonium hydro...

Embodiment 2

[0047] The preparation of core-shell structure emulsion deepening agent comprises steps:

[0048] 1) Add 0.3 g of dodecyl dimethyl benzyl ammonium chloride into the reactor, then add 0.3 octylphenol polyoxyethylene ether (OP-10) and 20 g of deionized water, heat and stir, and control the temperature to 50°C, after it is completely dissolved, slowly add 10 g of ethyl methacrylate monomer into the reactor, and keep stirring at a stirring speed of 1000 rpm for 40 minutes.

[0049] 2) Reduce the stirring speed to 250 rpm, adjust the reaction temperature to 80° C., and add 10 mL of 0.1% azoisobutylcyanoformamide aqueous solution with a certain concentration prepared in advance to the above reactor dropwise, Control the dropping time to 2.5 hours. After all the drops are completed, a transparent liquid with blue light is obtained. Cool down to 70°C, add 0.4 mL of a pre-prepared 1 mol / L potassium hydroxide aqueous solution, and adjust the pH to 10-11.

[0050] 3) In another reactor,...

Embodiment 3

[0057] The preparation of core-shell structure emulsion deepening agent comprises steps:

[0058] 1) Add 0.1 g of dodecyl dimethyl benzyl ammonium chloride and 0.1 g of cetyl trimethyl ammonium bromide into the reactor, and then add 0.2 g of fatty alcohol polyoxyethylene ether (AE0-3) , 0.3g of octylphenol polyoxyethylene ether (OP-10) and 20g of deionized water, heated and stirred, and the temperature was controlled at 40°C. After it was completely dissolved, 4g of methyl methacrylate was slowly added to the reactor, Stir continuously, the stirring speed is 900 rpm, and the stirring time is 30 minutes.

[0059] 2) Reduce the stirring speed to 200 rpm, adjust the reaction temperature to 78°C, and add 10 mL of 0.1% azobisisobutylamidine hydrochloride aqueous solution with a certain concentration prepared in advance to the above reactor drop by drop , control the dropping time to 2 hours. After all the drops are completed, a transparent liquid with blue light is obtained. The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com