Metal nanoparticle-foamy carbon catalyst, and preparation method and application thereof

A technology of metal nanoparticles and foamed carbon, which is applied in the direction of metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the cumbersome preparation process, difficult structure control, and high price and other problems, to achieve the effect of simple process, low equipment requirements and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] The main raw material used in this example-polymer nanoparticles: polymethylmethacrylate-b-poly(4-vinylpyridine) (PMMA 2250 -b-P4VP 286 , subscript indicates degree of polymerization, Mw / Mn=1.13) purchased from Polymer Source Company. Add propyne bromide in DMF solvent and obtain it through intramolecular cross-linking. The average particle size is 12 nanometers.

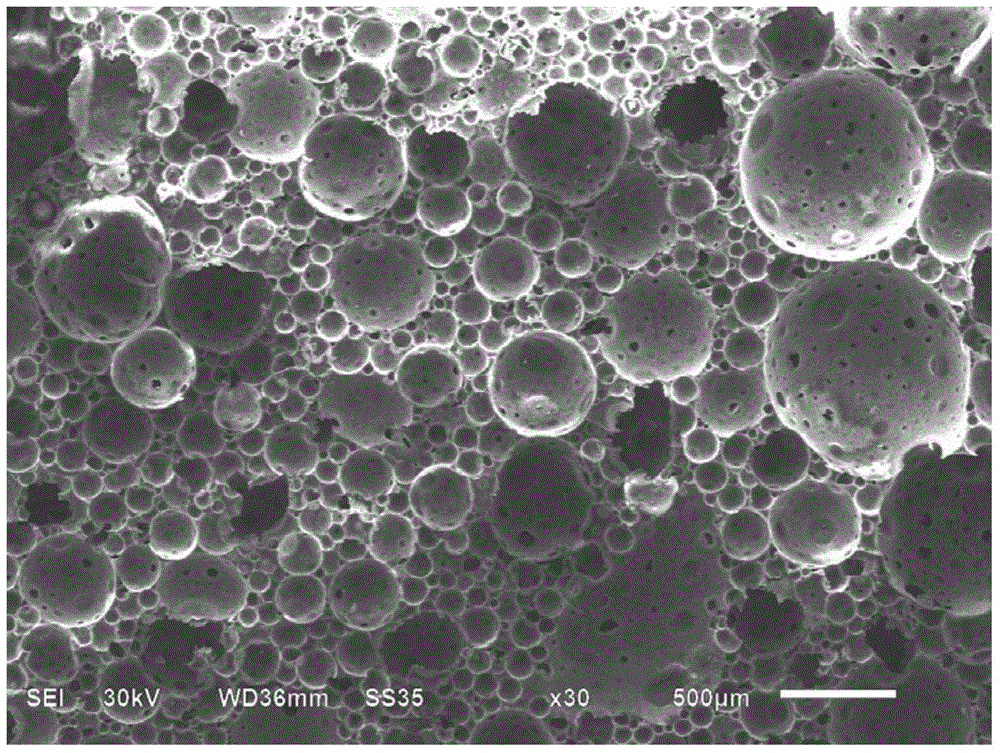

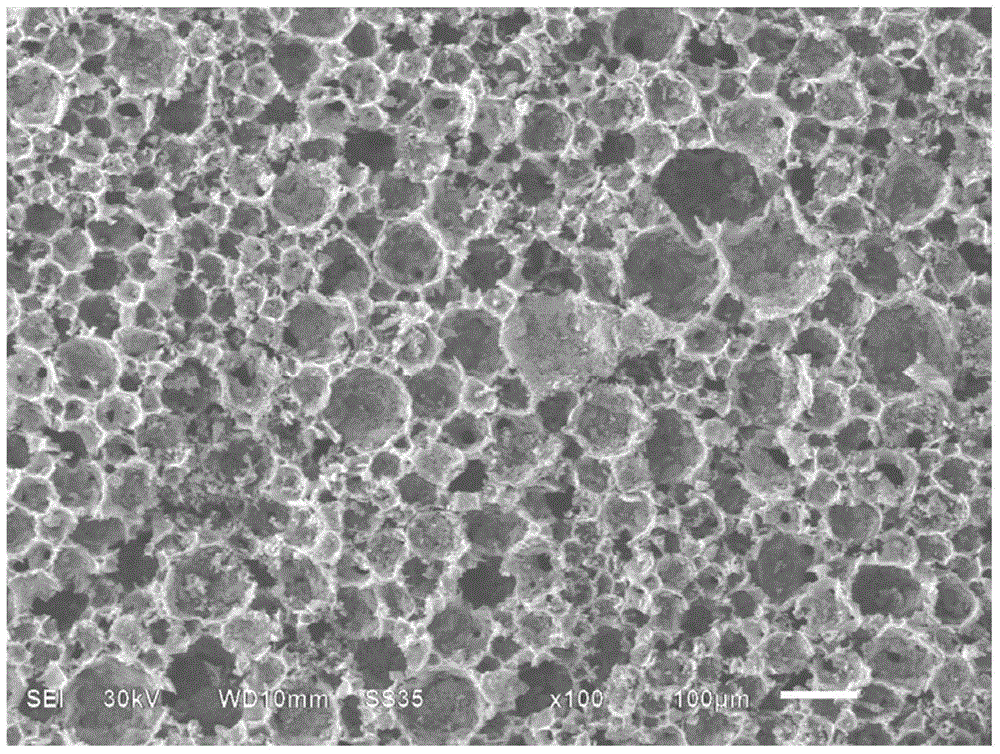

[0064] The preparation process of the metal nanoparticle / foamed carbon composite material of the present embodiment is specifically as follows: the polymer nanoparticle raw material (single molecular chain head-tail structure, the tail is a linear PMMA polymer, and the head is a cross-linked polymer) with an average particle diameter of 12nm P4VP polymer, wherein P4VP represents poly-4-vinylpyridine), is soluble in divinylbenzene and acrylonitrile mixed system. The volume ratio of divinylbenzene:acrylonitrile is 9:1, and the mass fraction of polymer nanoparticles relative to the oil phase is 0.16%. Under ...

Embodiment 2

[0069]The preparation process of the metal nanoparticle / foamed carbon composite material in this embodiment is as follows: Weigh the single-chain polymer nanoparticle PMMA-b-P4VP with a mass fraction of 0.16% relative to the oil phase, and dissolve it in a volume ratio of divinylbenzene : acrylonitrile=1:9 mixed oil phase, stirred until the solution is transparent. Prepare an aqueous solution of metal chloropalladate precursor with a mass fraction of 0.005%. Under the condition of stirring at 1000rpm, the aqueous solution containing the metal chloropalladate precursor was slowly added dropwise to the oil phase to form a high internal phase Pickering emulsion with an internal phase volume fraction of 75%. Add 1.5% initiator AIBN relative to the mass fraction of the oil phase to initiate the polymerization of the oil phase at 60° C. to form a polymeric foam material. Put the obtained polymeric foam material in tetrahydrofuran solvent, add 1 ml of hydrazine hydrate, and react at...

Embodiment 3

[0073] The preparation process of the metal nanoparticle / foamed carbon composite material in this embodiment is as follows: Weigh the single-chain polymer nanoparticle PMMA-b-P4VP with a mass fraction of 0.22% relative to the oil phase, and dissolve it in a volume ratio of divinylbenzene : acrylonitrile=9:1 mixed oil phase, stir until the solution is transparent. Prepare an aqueous solution of metal chloropalladate precursor with a mass fraction of 0.005%. Under the condition of stirring at 1000rpm, the aqueous solution containing the metal chloropalladate precursor was slowly added dropwise to the oil phase to form a high internal phase Pickering emulsion with an internal phase volume fraction of 75%. Add 1.5% initiator AIBN relative to the mass fraction of the oil phase to initiate the polymerization of the oil phase at 60° C. to form a polymeric foam material. Put the obtained polymeric foam material into a tetrahydrofuran solvent, add 1 ml of hydrazine hydrate, and react ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average cell diameter | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com