Innovative multi-protective function cable

A multi-protection, cable technology, applied in power cables, insulated cables, cable/conductor manufacturing, etc., can solve problems such as hidden safety hazards, economic losses, and difficulties, avoid performance degradation, improve bond strength, and improve mechanical properties. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] Preparation of component A in the anti-phagocytosis layer

[0080] First, 10 parts by weight of triaryl boron is dissolved in 15 parts by weight of dichloromethane, and then the dissolved material is added dropwise to 20 parts by weight of polyvinyl alcohol. Polyvinyl alcohol, to obtain a dichloromethane dispersion, then add 6 parts by weight of foamed silicone rubber, heat to 60-70 ° C, feed compressed air to volatilize the dichloromethane, and weigh the reactant to constant weight, the reaction is complete. Get the antifeedant complex and set aside.

[0081] Then take 100 parts by weight of silicone rubber, 6 parts by weight of hydroxy silicone oil, 25 parts by weight of white carbon black and 10 parts by weight of the anti-food agent compound prepared above, knead them into a group, heat to 160-180 ° C and knead for 1-2 hour, kneading for half an hour after evacuating to prepare the anti-phagocytosis layer component A, which is set aside. The performance of compone...

Embodiment 2

[0083] Preparation of component C in silica gel layer

[0084] Weigh 100 parts by weight of methyl vinyl silicone rubber, 15 parts by weight of white carbon black and 3 parts by weight of hydroxy silicone oil into a kneader and knead into a dough, then add 10 parts by weight of aluminum hydroxide, 10 parts by weight of Magnesium hydroxide, 5 parts by weight of calcium aluminum fluorosilicate, after kneading into agglomerates, raise the temperature to 150±10°C and knead for 1.5 hours, then raise the temperature to 180±10°C and vacuumize and knead for half an hour, then cool to obtain a silica gel layer Component C of the silica gel layer was tested for performance and recorded in Table 2 below.

Embodiment 3

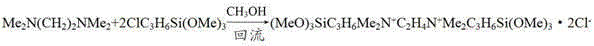

[0086] Preparation of single-core cables

[0087] Preparation of antifreeze rain liquid: Take 1mol of tetramethylethylenediamine and 2mol of chloropropyltrimethoxysilane, dissolve them in methanol, and reflux at 60-65°C for 2 hours to prepare cationic quaternary ammonium salt; take the above 100 parts by weight of the prepared cationic quaternary ammonium salt, 60 parts by weight of ethyl acetate, and 40 parts by weight of ethylene glycol monobutyl ether were mixed at room temperature and sealed for later use.

[0088] Coated heat insulation layer: After removing surface dirt and drying conductive metal wires (such as copper wires, copper-aluminum alloy wires, etc.), they are bundled or twisted to make a single conductor, and then the single conductor is placed in the casing or It is wrapped in glass cloth, then soaked in the MQ silicone resin solution with a solid content of 60wt% for 0.5-1 hour, then taken out, and dried at room temperature; repeat the above soaking steps tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com