Preparation method of flexible and foldable all-organic secondary battery

A secondary battery, organic technology, used in secondary batteries, electrolyte battery manufacturing, battery electrodes, etc., can solve problems such as long-term, random, large-scale folding and bending, human health threats, and human poisoning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

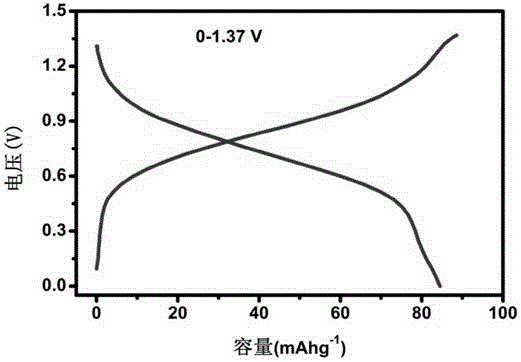

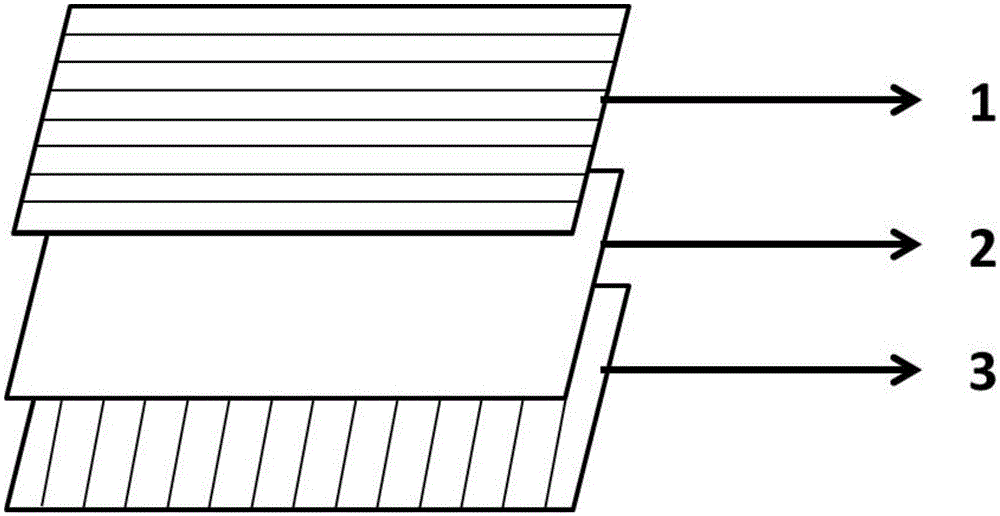

[0050] A method for preparing a flexible and foldable all-organic secondary battery. Its positive electrode material, negative electrode material and electrolyte are all made of organic polymer materials. The preparation process includes the following process steps:

[0051] 1. Preparation of negative electrode materials and thin films:

[0052]Using polyimide materials as the main body, a suitable working voltage can be obtained by adjusting the electron-withdrawing and electron-donating functional groups on the imine, and the inactive main chain functional group is used to adjust the polyimide or polymer intermediate in the conventional Solubility in solvents, in order to form a composite film with conductive carbon.

[0053] The specific manufacturing steps are as follows:

[0054] Preparation of polyamide

[0055] Naphthalene tetracarboxylic anhydride and 4,4'-diaminodiphenylether (ODA) are used as raw materials. ODA and naphthalenetetracarboxylic anhydride with a molar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com