A kind of saline-alkali soil improving agent and preparation method thereof

A technology for improving agent and saline-alkali soil, applied in chemical instruments and methods, other chemical processes, organic fertilizers, etc., can solve the problems of incomplete environmental safety evaluation, high preparation cost of new biological inoculants, and limited application time, etc. The effect of improving the rhizosphere soil environment, improving the salt tolerance of crops, and improving the soil buffering capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

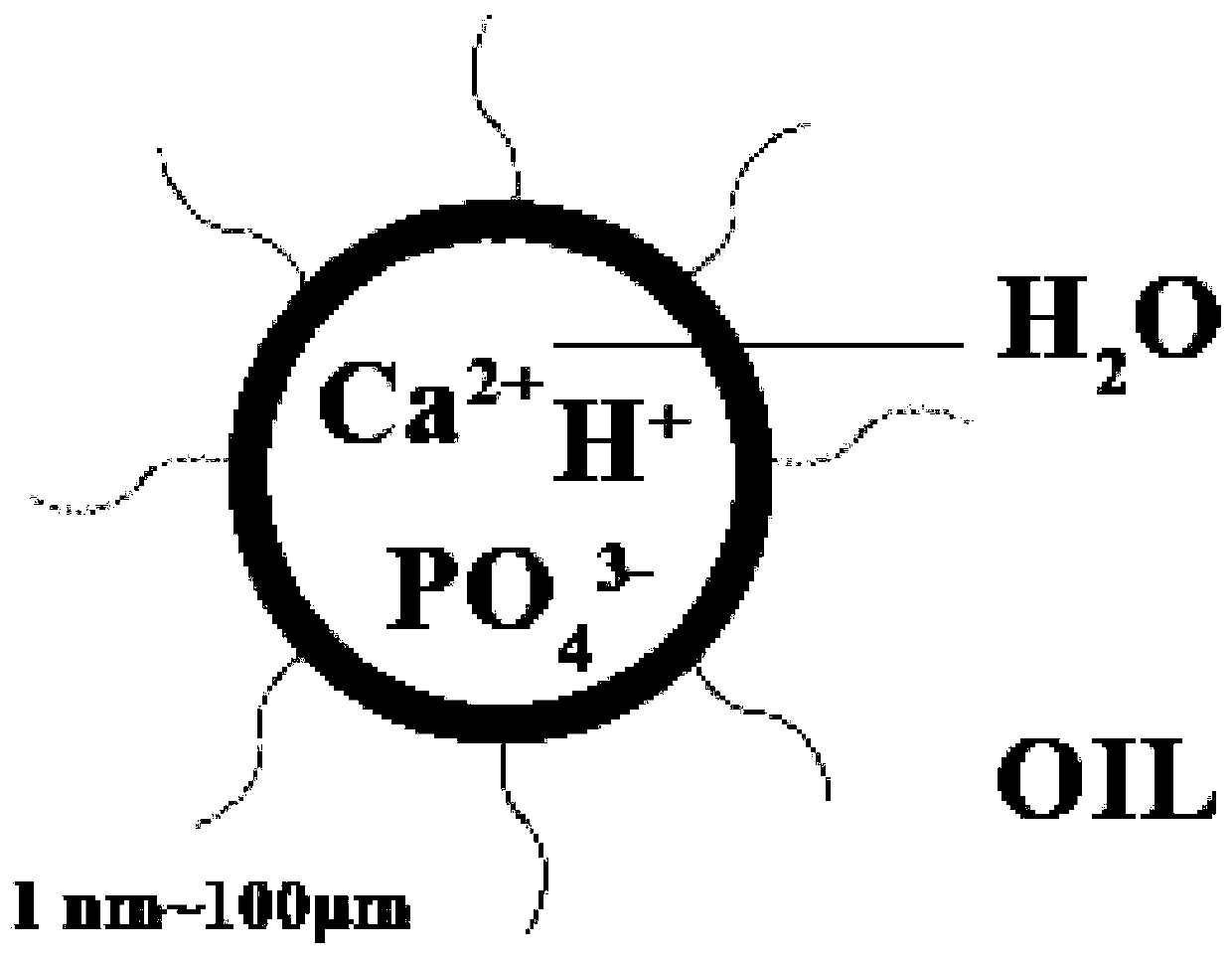

[0046] Embodiment 1, preparation saline land improved microcapsule suspension:

[0047] 1) Add 100ml deionized water to a 200ml reaction bottle, add 10g calcium citrate, 10g calcium nitrate, 5g calcium sulfate, 10g ammonium dihydrogen phosphate, 5g ferric chloride and 5g Tween-80 (polysorbate) In deionized water, stir at room temperature for 10 minutes until dissolved and dispersed evenly to obtain aqueous phase I;

[0048] 2) In a reactor equipped with heating and stirring equipment, add 200ml of biodiesel, 10g of n-butanol and 20g of SPAN-40 (SPAN), stir at room temperature for 20min until it dissolves and disperses evenly, and the oil phase II is obtained;

[0049] 3) Add the water phase I to the oil phase II, add 5 g of methacrylamide and 5 g of acrylic acid, stir and disperse at a speed of 3000 rpm for 10 min to make the system uniformly dispersed, and add the initiator azobisisobutyl Nitrile 0.8g, under nitrogen protection, heated to 50°C, stirred at a medium speed of 9...

Embodiment 2

[0050] Embodiment 2, preparation saline land improved microcapsule suspension:

[0051] 1) Add 100ml deionized water to a 200ml reaction flask, add 5g calcium citrate, 10g calcium acetate, 4g calcium sulfate, 6g amino acid calcium, 9g ammonium dihydrogen phosphate, 6g ammonium hydrogen phosphate and 10g alkylphenol polyoxyethylene Add ether (OP-10) into deionized water, stir at room temperature for 15 minutes until dissolved and dispersed evenly, and obtain aqueous phase I;

[0052] 2) In a reactor equipped with heating and stirring equipment, add 150 ml of the cyclohexane, 15 g of n-pentanol, and 10 g of agricultural milk 600#, and stir at room temperature for 15 minutes until it is dissolved and dispersed evenly, and the oil phase II is obtained;

[0053] 3) Add the water phase I to the oil phase II, add 6g of acrylamide, 4g of N-methylolacrylamide, and disperse at 2000rpm with high-speed shear stirring for 15min to make the system uniformly dispersed, and add the initiator ...

Embodiment 3

[0054] Embodiment 3, preparation saline land improved microcapsule suspension:

[0055] 1) Add 50ml of deionized water to a 100ml reaction bottle, add 6g of calcium citrate, 2g of calcium sulfate, 4g of calcium chloride, 10g of ferric ammonium citrate and 7g of Triton X-100 (TX-100) into the deionized In water, stir at room temperature for 10 minutes until dissolved and dispersed evenly to obtain aqueous phase I;

[0056] 2) In a reactor equipped with heating and stirring equipment, add 50 ml of turpentine-based vegetable oil, 2 g of isoamyl alcohol and 5 g of 1-hexanol, and stir at room temperature for 10 min until it dissolves and disperses evenly to obtain oil phase II.

[0057] 3) Add the water phase I to the oil phase II, add 4g of acrylamide, 1g of N,N-methylenebisacrylamide, and disperse at 2500rpm with high-speed shear stirring for 10min to make the system uniformly dispersed, add Initiator azobisisobutyronitrile 0.5g, nitrogen protection, heating to 60°C, stirring at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com