Eleostearic acid ester alkylated compound containing phenolic hydroxyl, and preparation method and application of eleostearic acid ester alkylated compound

A technology for the alkylation of oleic acid esters, which is applied in the field of alkylated compounds containing phenolic hydroxyl esters and their preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

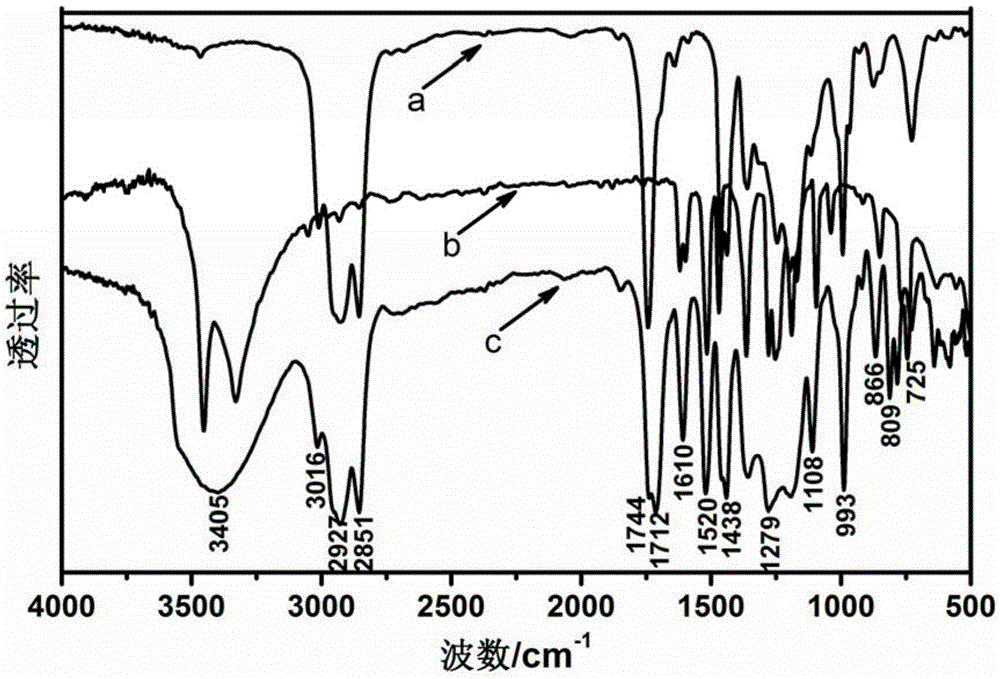

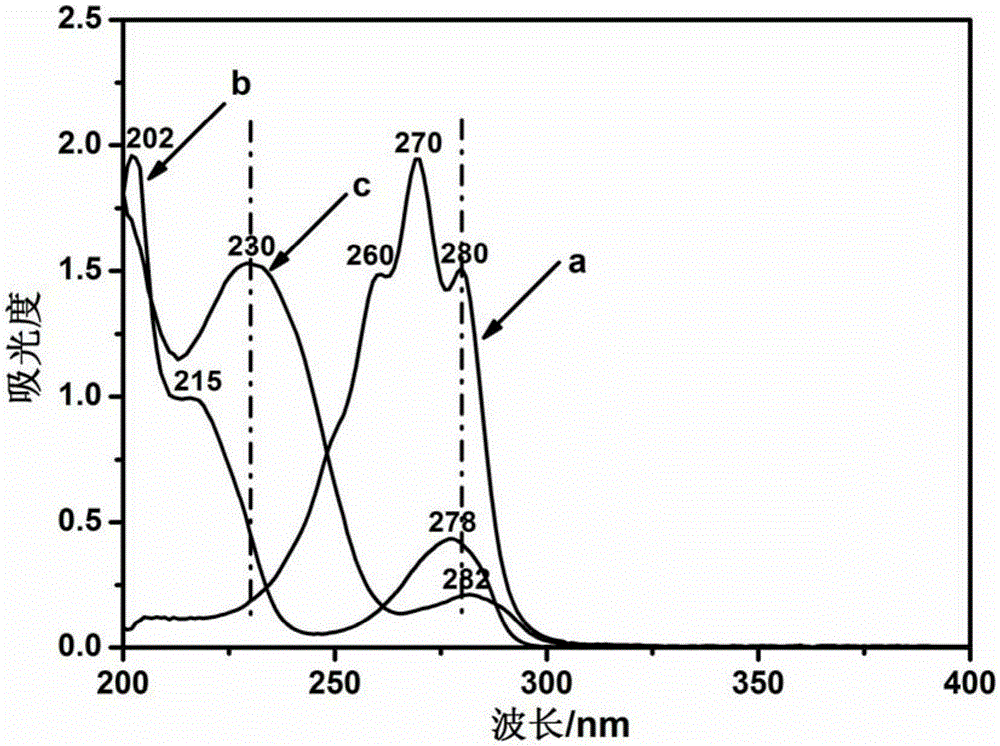

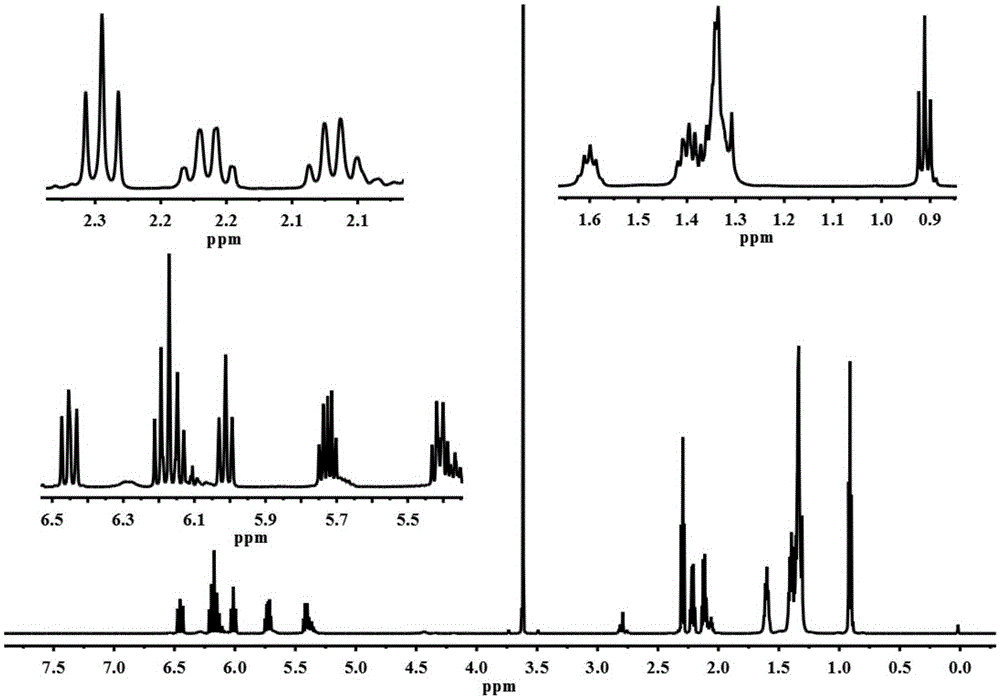

Examples

Embodiment 1

[0042] According to the following steps to prepare the alkylated compound containing phenolic hydroxyl oleic acid ester:

[0043] (1) Synthesis and separation and purification of methyl trophic acid: add 43.6 g tung oil (0.05 mol, tung oil is calculated as acid glycerol (872)) in a 250 mL three-necked flask, install a condensing reflux device, and heat the constant temperature water bath to 70 After ℃, add the prepared NaOH / methanol solution (0.436g / 9.6g), wherein methanol: tung oil=6:1 (mol / mol), methyl alcohol 0.3mol (9.6g); NaOH is 1% (0.436g) of tung oil quality g); turn on the magnetic stirring, and stop the reaction after reacting for about 1 hour; add an appropriate amount of phosphoric acid to neutralize, transfer the reaction solution to a separatory funnel while it is still hot, and separate the glycerin layer (lower layer); Wash 3 to 4 times, remove the water phase in the lower layer, distill off methanol and most of the water under reduced pressure, and dry with an...

Embodiment 2

[0056] According to the following steps to prepare the alkylated compound containing phenolic hydroxyl oleic acid ester:

[0057] (1) Synthesis and separation and purification of ethyl chertate:

[0058]In a 250mL three-necked flask, add 43.6g tung oil (0.05mol, tung oil is calculated as acid glyceryl tungate (872)), install a condensation reflux device, and after the constant temperature water bath is heated to 60°C, add the prepared KOH / ethanol solution, wherein Ethanol: tung oil=5:1 (mol / mol), ethanol 0.25mol; KOH is 2% of the quality of tung oil; turn on the magnetic stirring, and stop the reaction after reacting for about 80min; add an appropriate amount of phosphoric acid for neutralization, and transfer the reaction solution to Separate the funnel, let it stand, separate the glycerol layer (lower layer); wash the upper liquid with hot distilled water 3 to 4 times, remove the lower water phase, distill under reduced pressure to remove ethanol and most of the water, etc.,...

Embodiment 3

[0064] According to the following steps to prepare the alkylated compound containing phenolic hydroxyl oleic acid ester:

[0065] (1) Synthesis and separation and purification of n-propyl chertate:

[0066] Add 43.6g tung oil (0.05mol, tung oil is calculated as tung-glyceride 872) in a 250mL three-necked flask), install a condensation reflux device, and after the constant temperature water bath is heated to 80°C, add the prepared KOH / n-propanol solution, Among them, n-propanol: tung oil=8:1 (mol / mol), n-propanol 0.4mol; KOH is 2% of the quality of tung oil; turn on the magnetic stirring, after reacting for about 50min, stop the reaction; add an appropriate amount of phosphoric acid for neutralization, while hot Transfer the reaction solution to a separatory funnel, let it stand, and separate the glycerin layer (lower layer); wash the upper liquid with hot distilled water for 3 to 4 times, remove the lower water phase, and distill under reduced pressure to remove n-propanol and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com