Core-shell type ultra-micro electrode prepared through coaxial electrostatic spinning and preparation method thereof

A technology of coaxial electrospinning and ultra-micro electrodes, which is applied in separation methods, filament/wire forming, chemical instruments and methods, etc., can solve the problems that the ablation process is not easy to control, and avoid the process of electrode surface modification, The effect of a wide range of options and a simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

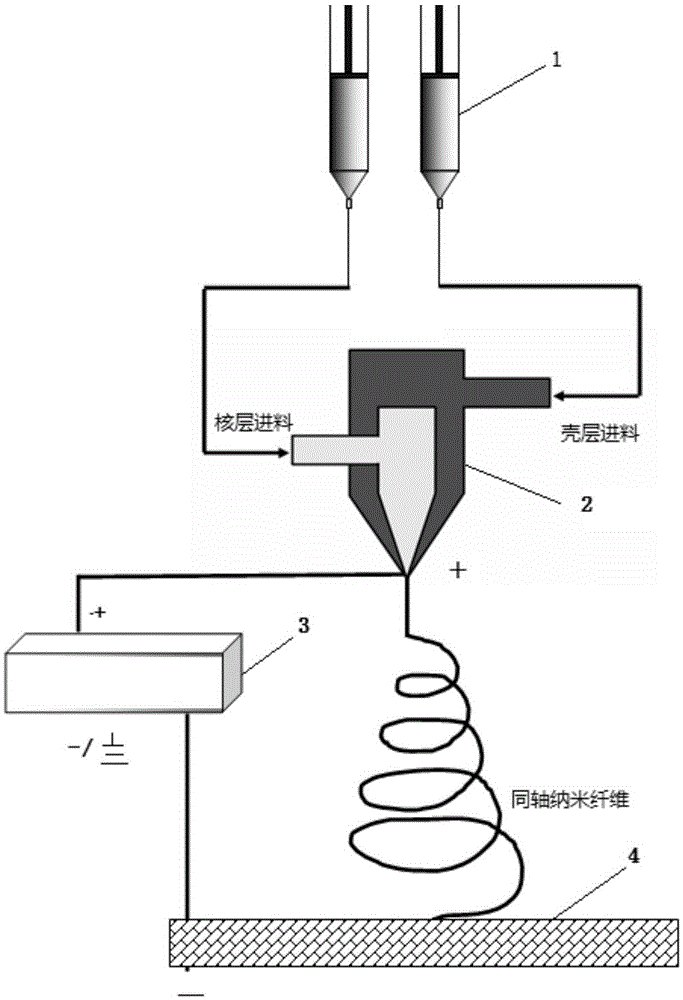

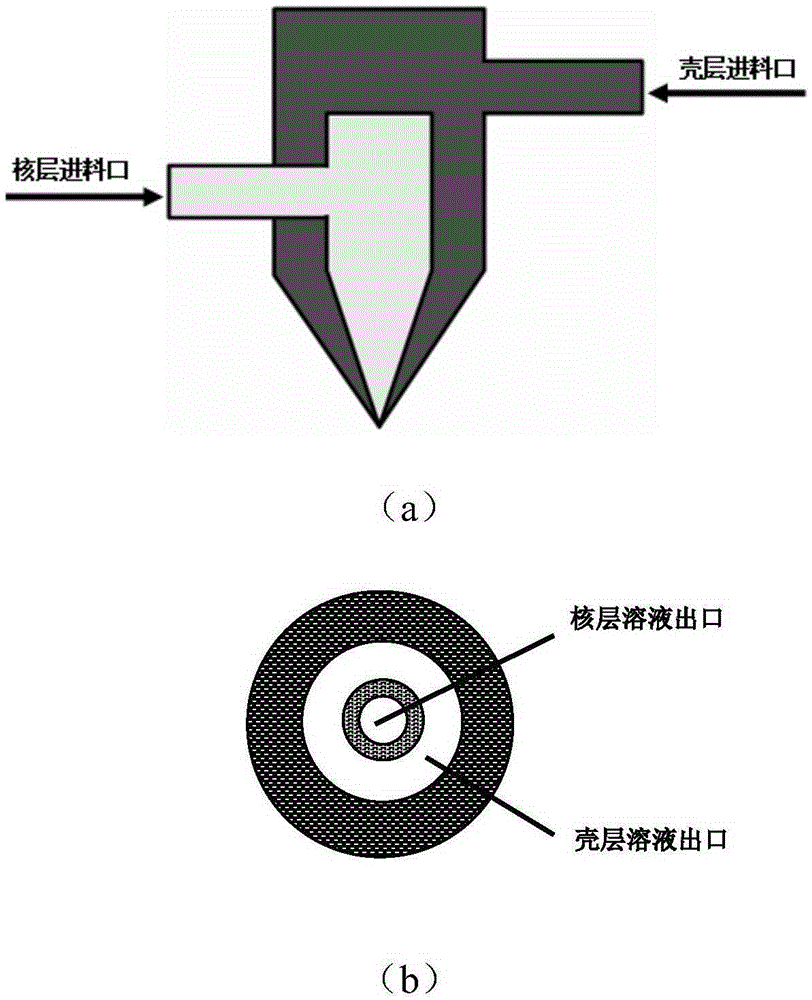

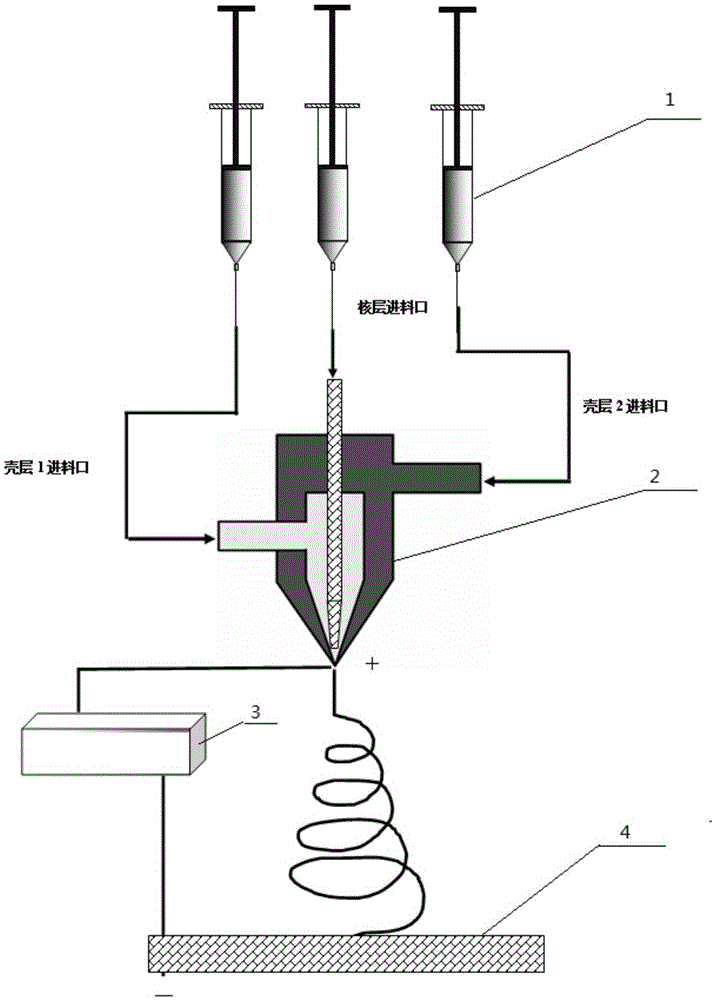

Method used

Image

Examples

Embodiment 1

[0063] The ATP sensor prepared in this example has a core-shell double-layer structure; the core layer is composed of polyvinylpyrrolidone (PVP) and graphite powder, and the shell layer is composed of gelatin and graphene. PVP plays the role of plasticization and molding in the core layer, and graphite powder plays the role of electron transfer. Gelatin plays a plasticizing role in the shell, and its molecular structure is rich in carbonyl and ether groups, which can screen and enrich the target detection substance (ATP). Graphene is the second component of the shell, its huge specific surface area and good conductivity are conducive to the attachment of ATP and improve the electron transfer efficiency between ATP and graphene.

[0064] Preparation of nuclear layer solution: 1 g of polyvinylpyrrolidone (PVP; M w =1,300,000) into 21 mL of absolute ethanol, then 7 mL of glacial acetic acid, and stirred for 3 to 5 hours to obtain a PVP solution with a mass concentration of 4%. ...

Embodiment 2

[0071]The ATP sensor prepared in this example has a core-shell double-layer structure, and the composition of the core layer is based on Example 1 (PVP+graphite powder), and the conductive phase in the core layer is improved by adding a certain amount of toluene acetylene. Density and electron transport rate, thereby improving the detection accuracy of the sensor.

[0072] Preparation of the nuclear layer solution: Add 1 g of polyvinylpyrrolidone (PVP; Mw=1,300,000) into 21 mL of absolute ethanol, then add 7 mL of glacial acetic acid, and stir for 3 to 5 hours to prepare a PVP solution with a mass concentration of 4%. In order to improve the transport capacity of electrons in the electrode, add 1.0 g of ultrafine graphite powder (average particle size is 1.2 microns) and 0.5 g of tolanin to the prepared nuclear layer solution, and stir for 1 hour to obtain a nuclear layer spinning silk solution.

[0073] Preparation of the shell solution: the same as in Example 1.

[0074] P...

Embodiment 3

[0079] Preparation of nuclear layer solution: same as in Example 2.

[0080] Preparation of shell solution: due to the large electrostatic repulsion between chitosan molecules, it is not easy to directly carry out electrospinning, so a certain proportion (1:1) of polyethylene oxide is added in this embodiment to improve chitosan Electrospinning performance. First, 0.5 g of chitosan and polyethylene oxide (PEO) were respectively added into 5.5 mL of glacial acetic acid, and stirred for 1 hour to obtain a solution with a mass concentration of 8%. Then the two solutions were mixed and stirred for 30 minutes to obtain a mixed solution containing chitosan and PEO.

[0081] Preparation of coaxial ultramicroelectrode fibers: Fill the prepared core layer and shell layer spinning solutions into two 5mL syringes respectively, and fix the syringes on two syringe pumps respectively. According to the different positions of the mixed solution in the coaxial electrode layer, connect the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com