Preparation method and application of hapten and artificial antigen capable of being used for detecting crystal violet and malachite green together

A malachite green and artificial antigen technology, applied in the field of immunochemistry, can solve the problems of potential safety hazards of raw materials, poor stability of hapten, large difference between batches of antigens, etc., and the temperature requirements are not harsh, the product properties are stable, and the cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

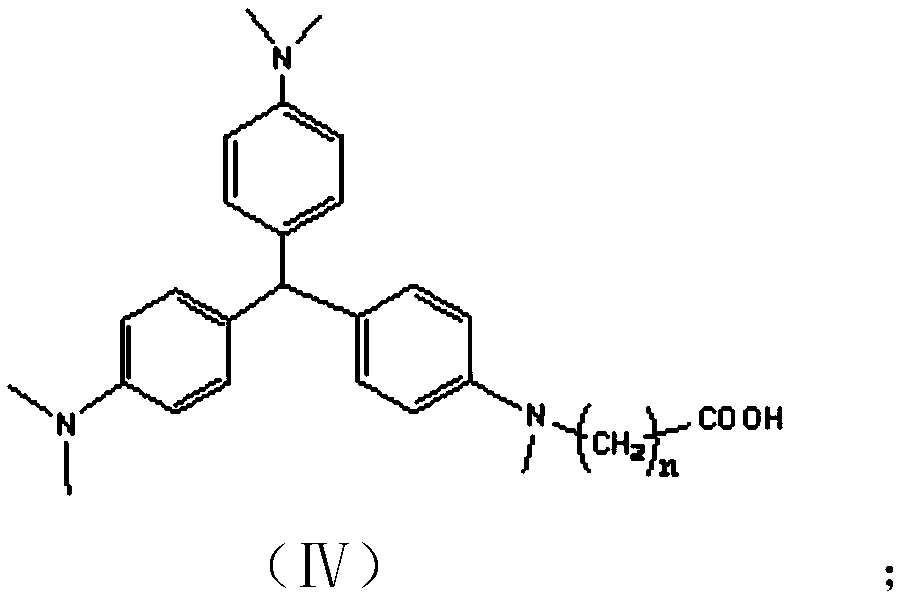

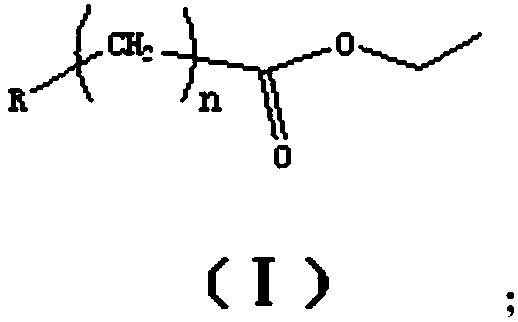

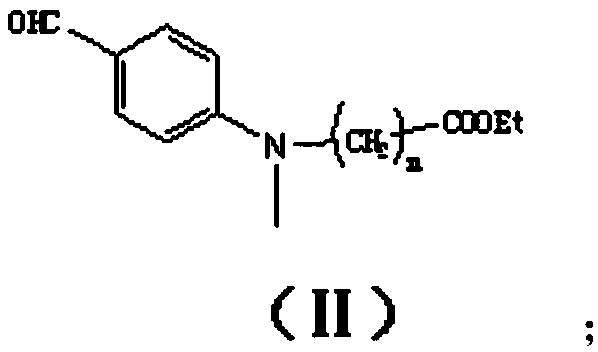

[0056] (1) Get 2.0g (14.8mmol) of 4-methylaminobenzaldehyde in a 50ml round bottom flask, then add 20ml dehydrated alcohol successively, 3.7g (22.2mmol) of ethyl 2-bromoacetate and 2.0g of potassium carbonate ( 14.8 mmol). Reflux at 80-90°C for 3h. After the reaction is complete, remove the solvent under reduced pressure, add 40ml of purified water, extract twice with ethyl acetate, remove the solvent under reduced pressure, crystallize petroleum ether to obtain the desired compound a 1 2.6g.

[0057] (2) 2.6g compound a 1 Dissolve in 13ml of ethanol, add 3.6g (29.4mmol) of N,N-dimethylaniline and 4.0g (29.4mmol) of zinc chloride, and reflux at 80-90°C for 24h. After the reaction was completed, the solvent was removed under reduced pressure. Add 40ml of purified water, extract with ethyl acetate, remove the solvent under reduced pressure, and purify by column chromatography to obtain the desired compound b 1 2.3 g (ethyl acetate / petroleum ether, 1 / 10, v / v).

[0058] (3) ...

Embodiment 2

[0062] (1) Take 2.0g (14.8mmol) of 4-methylaminobenzaldehyde in a 50ml round bottom flask, then add 20ml of absolute ethanol, 4.3g (22.2mmol) of ethyl 4-bromobutyrate and 2.0g of potassium carbonate (14.8 mmol). Reflux at 80-90°C for 3h. After the reaction is complete, remove the solvent under reduced pressure, add 40ml of purified water, extract twice with ethyl acetate, remove the solvent under reduced pressure, crystallize petroleum ether to obtain the desired compound a 2 2.9g.

[0063] (2) 2.9g compound a 2 Dissolve in 13ml of ethanol, add 3.5g (29.1mmol) of N,N-dimethylaniline and 4.0g (29.1mmol) of zinc chloride, and reflux at 80-90°C for 24h. After the reaction was completed, the solvent was removed under reduced pressure. Add 40ml of purified water, extract with ethyl acetate, remove the solvent under reduced pressure, and purify by column chromatography to obtain the desired compound b 2 2.0 g (ethyl acetate / petroleum ether, 1 / 10, v / v).

[0064] (3) 2.0g compou...

Embodiment 3

[0068] (1) Take 2.0g (14.8mmol) of 4-methylaminobenzaldehyde in a 50ml round bottom flask, then add 20ml of absolute ethanol, 5.0g (22.2mmol) of ethyl 6-bromohexanoate and 2.0g of potassium carbonate (14.8 mmol). Reflux at 80-90°C for 3h. After the reaction is complete, remove the solvent under reduced pressure, add 40ml of purified water, extract twice with ethyl acetate, remove the solvent under reduced pressure, crystallize petroleum ether to obtain the desired compound a 3 2.7g.

[0069] (2) 2.7g compound a 3 Dissolve in 13ml of ethanol, add 2.9g (24.3mmol) of N,N-dimethylaniline and 3.3g (24.3mmol) of zinc chloride, and reflux at 80-90°C for 24h. After the reaction was completed, the solvent was removed under reduced pressure. Add 40ml of purified water, extract with ethyl acetate, remove the solvent under reduced pressure, and purify by column chromatography to obtain the desired compound b 3 2.6 g (ethyl acetate / petroleum ether, 1 / 10, v / v).

[0070] (3) 2.6g compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reaction rate constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com