Encapsulated pesticide composition

The technology of a pesticide composition and a microcapsule is applied in the field of herbicidal compositions with improved performance, which can solve the problems of low utilization rate of drug efficacy and the like, and achieve the advantages of improving the safety of crops, reducing labor costs, and improving the utilization rate of active ingredients. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

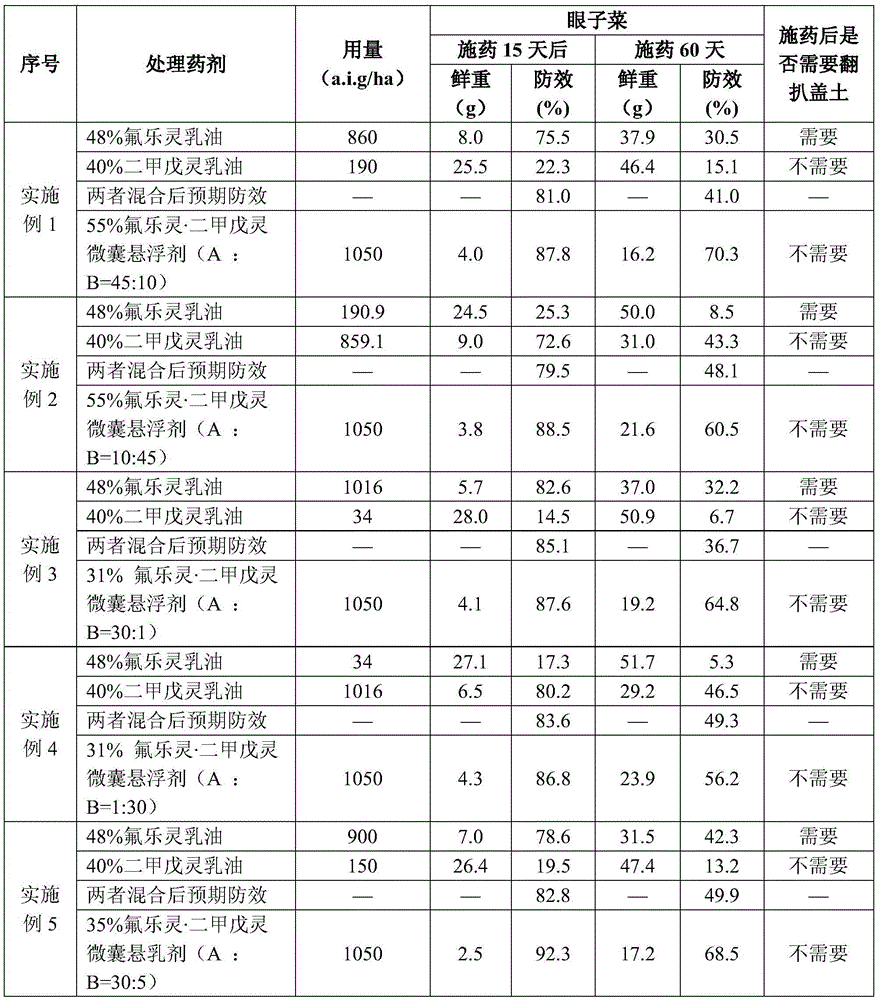

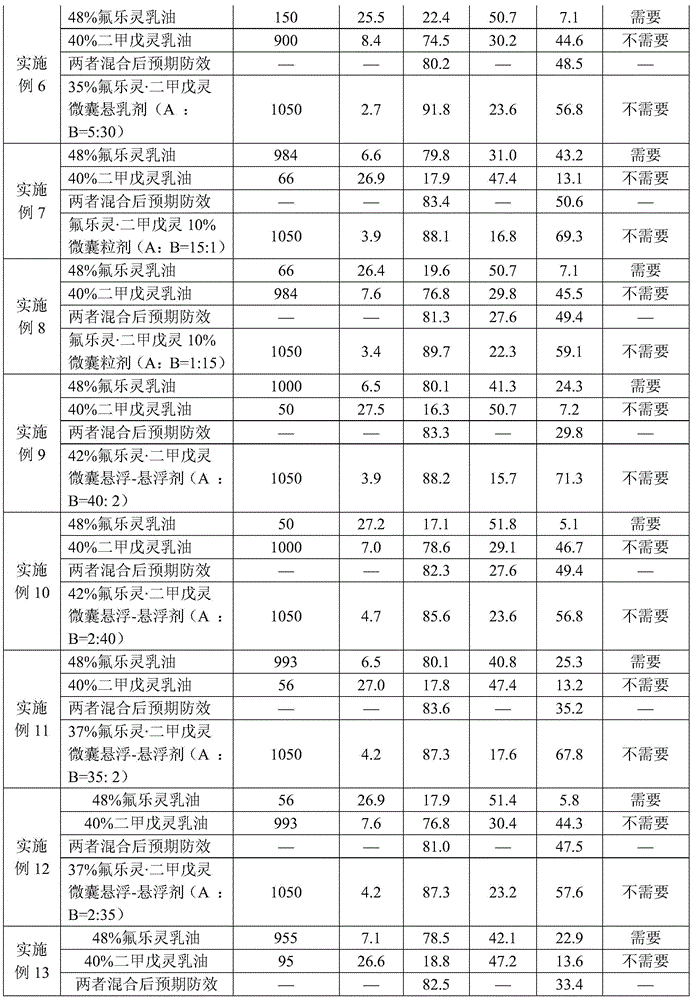

Embodiment 155

[0038] Example 155% trifluralin pendimethalin microcapsule suspension (active ingredient A:active ingredient B=45:10)

[0039] Add 45% of the active ingredients trifluralin and 10% of pendimethalin into 12% solvent turpentine vegetable oil and stir evenly, then add 1.8% of stabilizer triphenyl phosphite and 2% of emulsifier polyoxyethylene castor oil, Add 1.5% glyceryl lactate as initiator, add 10% vesicle-forming monomer toluene diisocyanate and stir evenly to obtain an oil phase; mix 2.5% dispersant acrylic acid-acrylate copolymer with 2% antifreeze propylene glycol, 0.3% preservative sodium benzoate, Thickener Xanthan Gum 1.8% is added to water (water up to 100%) and stirred evenly to obtain the water phase; preheat the oil and water to 45°C, then pour the oil phase into the water phase and start high-speed emulsification until a stable The emulsion was kept at temperature for 4 hours, and a 50% trifluralin pendimethalin microcapsule suspension (active ingredient A:active i...

Embodiment 255

[0040] Example 255% trifluralin pendimethalin microcapsule suspension (active ingredient A:active ingredient B=10:45)

[0041] Add 10% of the active ingredients trifluralin and 45% of pendimethalin into the solvent methyl ester soybean oil 13% and stir evenly, then add the stabilizer epoxy soybean oil 2%, emulsifier fatty alcohol polyoxyethylene ether 1.5% , initiator 1-octyn-3-ol 0.8%, add vesicle-forming monomer toluene diisocyanate 11% and stir evenly to obtain an oil phase; dispersant polymerized carboxylic acid sodium salt 2% and antifreeze agent ethylene glycol 2% 1.8% of the preservative Kaison and 0.8% of the thickener xanthan gum are added to water (the water is supplemented to 100%) and stirred evenly to obtain the water phase. Preheat the oil and water to 40°C, then pour the oil phase into the water phase and turn on high-speed emulsification to obtain a stable emulsion, keep the temperature for 6 hours, and use the interfacial polymerization method to obtain a micr...

Embodiment 331

[0042] Example 331% Trifluralin · Pendimethalin microcapsule suspension (active ingredient A:active ingredient B=30:1)

[0043] Add 30% of the active ingredients trifluralin and 1% of pendimethalin into the solvent 15% turpentine vegetable oil and stir evenly, then add the emulsifier polyoxyethylene lauryl ether 6%, and the initiator fatty acid glyceride 4% and stir evenly to obtain Oil phase; 4.5% of antifreeze agent glycerin, 1% of potassium dihydrogen phosphate as a stabilizer, 14% of formaldehyde-urea prepolymer of encapsulating prepolymer are added to water (water is supplemented to 100g) and stirred to obtain an aqueous phase; Preheat the oil and water to 60°C, then pour the oil phase into the water phase and turn on high-speed emulsification, wait until the emulsion is stable, add dilute hydrochloric acid in batches to adjust the pH=2.5 to undergo polycondensation reaction, keep the temperature for 4 hours, and then add the dispersant Sodium lignosulfonate 3%, thickener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com