A shape-memory highly elastic active nanofiber scaffold and its application

A nanofiber, high-elasticity technology, applied in the field of preparation of bioabsorbable shape memory biomaterials, can solve the problems of mismatched biomechanical properties, biocompatibility and insufficient anticoagulation, and achieve good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

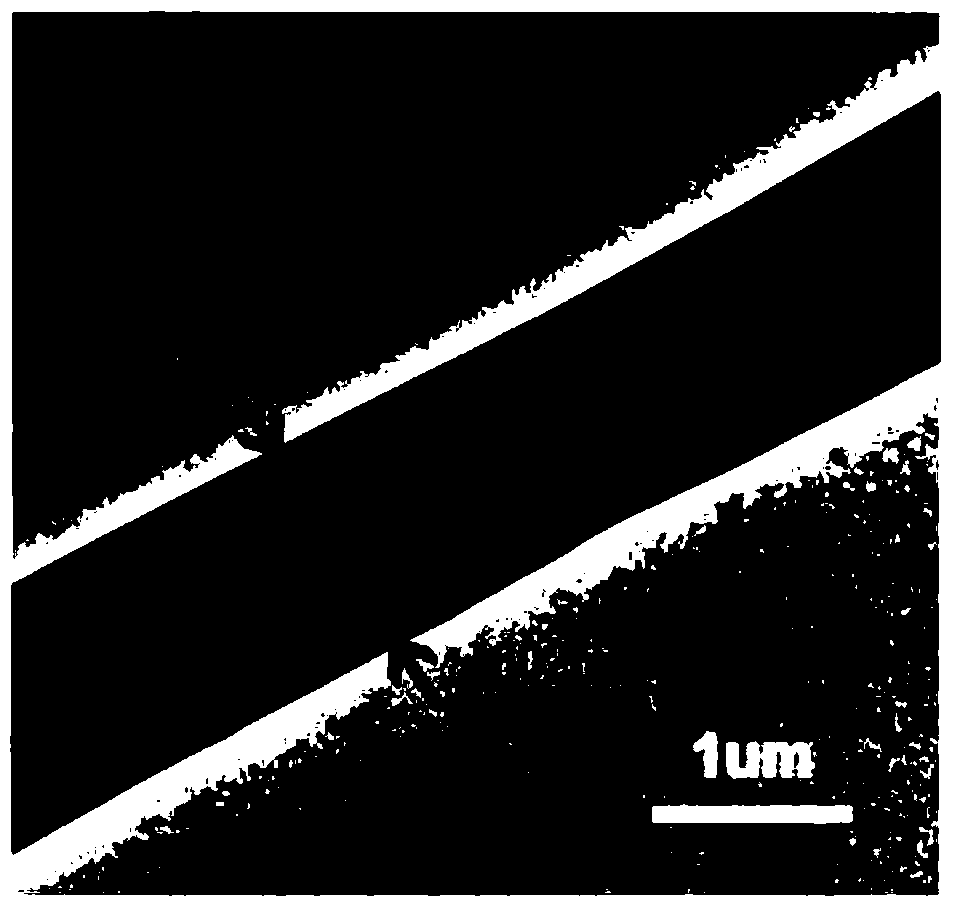

Image

Examples

Embodiment 1

[0064] (1) Take 2g of linear elastic polyester PCT 8-2 with an electronic balance and dissolve it in 18g of dichloromethane: in the mixed solvent of hexafluoroisopropanol=50:50, stir until completely dissolved to obtain linear elastic polyester PCT 8-2 PCT8-2 spinning solution with a final concentration of 10% (w / w).

[0065] (2) Select a 5mL syringe and a needle with an inner diameter of 1.2mm to extract the PCT 8-2 spinning solution with a concentration of 10% (w / w) obtained in step (1), and fix it on the electrospinning device for electrospinning Silk, the process parameters are: the spinning solution injection rate is 2mL / h, the voltage is 15kV, the receiving distance is 20cm, the ambient temperature is 22°C, and the ambient relative humidity is 40%. Aluminum foil was used as the receiving device, and the fiber membrane was spun for 2 hours, and the collected fiber membrane was dried in a vacuum oven at room temperature for 24 hours to obtain a shape-memory highly elastic ...

Embodiment 2

[0068] (1) Weigh 2g of linear elastic polyester PCT 9-1 with an electronic balance and dissolve it in 16g of DMF: trifluoroacetic acid = 50:50 mixed solvent, stir until completely dissolved to obtain linear elastic polyester PCT 9-1 PCT9-1 spinning solution with a final concentration of 8% (w / w).

[0069] (2) Select a 5mL syringe and a needle with an inner diameter of 1.2mm to extract the PCT 9-1 spinning solution with a concentration of 8% (w / w) obtained in step (1), and fix it on the electrospinning device for electrospinning Silk, the process parameters are: the spinning solution injection rate is 2mL / h, the voltage is 15kV, the receiving distance is 20cm, the ambient temperature is 22°C, and the ambient relative humidity is 40%. Aluminum foil was used as the receiving device, and the fiber membrane was spun for 2 hours, and the collected fiber membrane was dried in a vacuum oven at room temperature for 24 hours to obtain a shape-memory highly elastic active nanofiber scaff...

Embodiment 3

[0071] Example 3: Heparin Coaxial Spinning Stent Loaded with Growth Factors

[0072] (1) Weigh 2g of linear elastic polyester PCT 8-2 with an electronic balance and dissolve it in 16g of dimethyl sulfoxide: trifluoroacetic acid = 50:50 mixed solvent, stir until completely dissolved, and obtain linear elastic polyester PCT 8-2 PCT spinning dope A with a final concentration of 8% (w / w), used as the core layer for coaxial spinning.

[0073] (2) 400 mg of heparin, 600 mg of type I collagen and 1000 mg of linear elastic polyester PCT8-2 were dissolved in 16 g of hexafluoroisopropanol to obtain a final concentration of linear elastic polyester PCT 8-2 of 8% (w / w ) of heparin / collagen / elastic polyester spinning dope B, as the shell layer of coaxial spinning.

[0074] (3) Using coaxial spinning needles, the two kinds of spinning solutions were fixed on the electrospinning device through different syringe pumps for electrospinning. The process parameters were: the advancing speed of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com