Catalytic cracking catalyst containing modified molecular sieve and preparation method of catalytic cracking catalyst

A catalytic cracking and molecular sieve technology, applied in molecular sieve catalysts, catalytic cracking, physical/chemical process catalysts, etc., can solve problems such as unfavorable heavy metals, large particles of rare earth precipitates, unfavorable uniform dispersion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

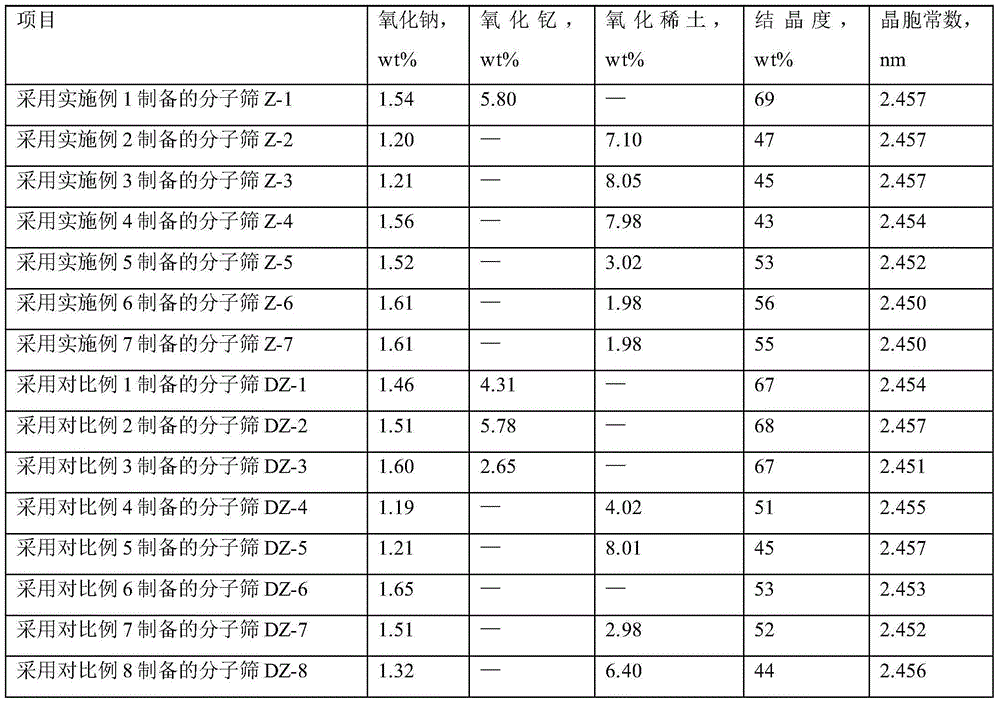

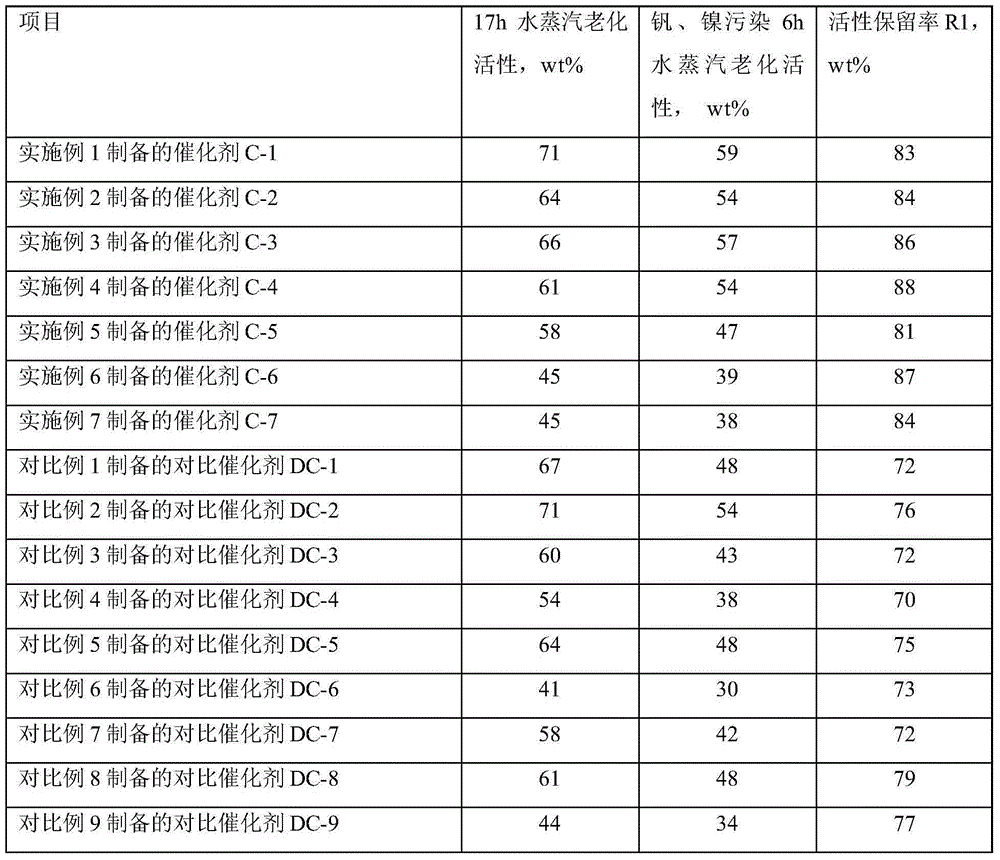

Examples

Embodiment 1

[0053] 16g of citric acid, 4g of ethylene glycol, 54g of yttrium nitrate and 128g of ammonium oxalate were simultaneously added to the self-made yttrium-containing Y-type molecular sieve slurry Y-1, and stirred at a temperature of 55°C for 20 minutes. Filtration, washing, and calcination of the filter cake at 600° C. and 100% water vapor atmosphere for 2 hours to obtain the modified molecular sieve Z-1 of the present invention.

[0054] Add 600 g (dry basis) of molecular sieve Z-1 into 1.2 L of deionized water, and perform sand milling to obtain molecular sieve slurry Z-1J. Mix 619g of alumina sol, 1499g of kaolin, and 2.2L of water for beating, then add molecular sieve slurry Z-1J, continue stirring for 30 minutes, homogenize, spray dry and form, roast, wash with water, and dry to obtain catalyst C-1 of the present invention.

Embodiment 2

[0056] Mix and beat 798g (dry basis) REUSY molecular sieve, 16g (dry basis) ZSM-5 molecular sieve, and water according to the weight ratio of molecular sieve (dry basis): water = 1:3 to form a molecular sieve slurry, add 110g ethylenediaminetetra Acetic acid, 104 mL of rare earth nitrate, and ammonia water were used to adjust the pH value of the molecular sieve slurry in the range of 7.5 to 8.0, then 23 g of ethanol was added, and stirred at room temperature (25° C.) for 30 minutes. Filter, wash, and dry the filter cake at 200°C. The modified molecular sieve Z-2 of the present invention is obtained.

[0057] 600g (dry basis) of molecular sieve Z-2 was added into 1.2L of deionized water, and subjected to sand milling to obtain molecular sieve slurry Z-2J. Mix 619g of alumina sol, 1513g of diatomaceous earth, and 2.2L of water for beating, then add molecular sieve slurry Z-2J, continue to stir for 30 minutes, spray dry after homogenization, roast, wash, and dry to obtain cataly...

Embodiment 3

[0059] Mix 798g (dry basis) REUSY molecular sieve and water according to the weight ratio of molecular sieve (dry basis): water = 1:3 to form a slurry, add 155g urea and 85g lanthanum nitrate in sequence, stir at room temperature (25°C), and use ammonia water Adjust the pH value of the molecular sieve slurry in the range of 6.5-7.0, then add 14 g of ethylene glycol, and continue stirring for 1.5 hours at room temperature (25° C.). Dry at 250°C. The modified molecular sieve Z-3 of the present invention is obtained.

[0060] Add 600 g (dry basis) of molecular sieve Z-3 into 1.2 L of deionized water, and perform sand milling to obtain molecular sieve slurry Z-3J. Mix 1054g kaolin, 587g pseudo-boehmite, and 2.2L water for beating, add 60mL hydrochloric acid, stir for 1 hour, then add molecular sieve slurry Z-3J, stir for 15min, then add 515g aluminum sol, continue stirring for 30min to form a gel, homogeneous Afterwards, it is formed by spray drying, calcined, washed with water,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com