Composite photocatalytic antibacterial material and preparation method thereof

A technology of composite photocatalytic and antibacterial materials, which is applied in the field of composite photocatalytic antibacterial materials and their preparation to achieve the effect of avoiding low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] 3. Deposition of Mn-doped ZnO on NaYF 4 : Yb,ErSiO 2 A core-shell structure composite antibacterial material is formed on the surface, and its preparation method comprises the following steps:

[0037] (1) NaYF 4 :Yb,ErSiO 2 Nanoparticles with core-shell structure are ultrasonically dispersed in diethylene glycol to obtain a suspension system;

[0038] (2) Add zinc salt and manganese salt to the above suspension system in a certain proportion, stir at room temperature for 1 hour, then raise the temperature to 180°C, and reflux for 1-6 hours;

[0039] (3) The solid product was centrifuged and calcined at 500°C for 2 hours to obtain a manganese-doped zinc oxide deposited NaYF with visible / near-infrared photocatalytic activity. 4:Yb,ErSiO 2 Photocatalytic antibacterial materials with core-shell structure.

Embodiment 1

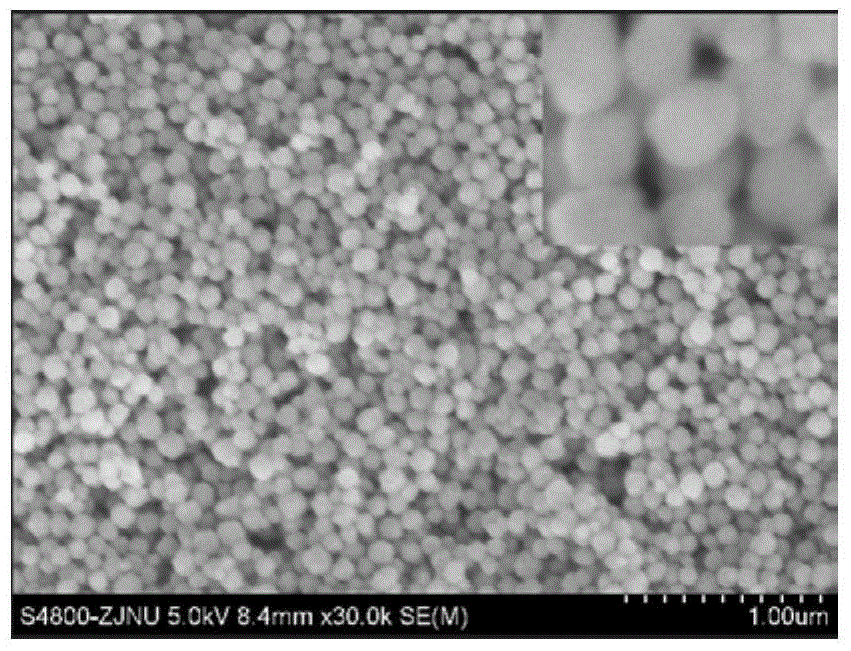

[0042] 0.78mmol yttrium acetate, 0.2mmol ytterbium acetate, 0.02mmol erbium acetate, 1mmolNaCl and 36mmolNH 4 F was dissolved in 35ml of ethylene glycol and stirred evenly, poured into a microwave digestion tank, placed in a microwave digestion apparatus at 180°C for 1 hour, washed and dried to obtain NaYF 4 : Yb, Er up-conversion fluorescent material, the microstructure of the resulting product is as follows figure 1 shown.

Embodiment 2

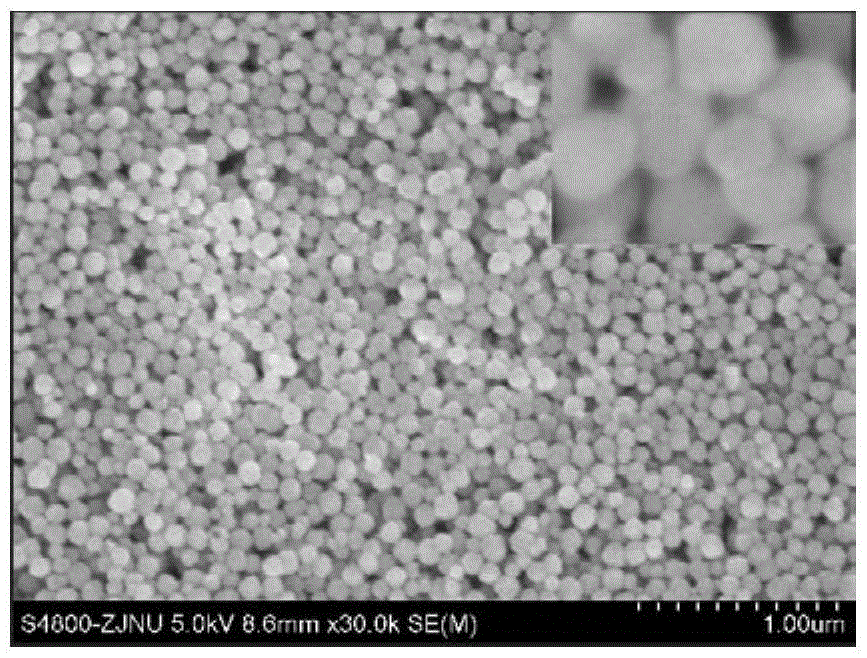

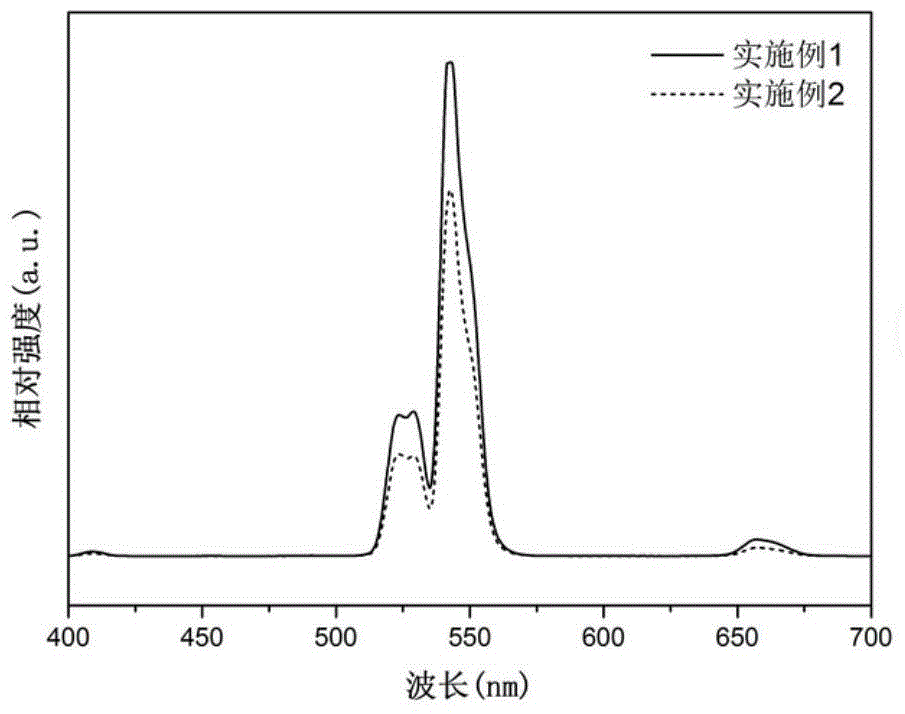

[0044] Using the process in Example 1, reducing the amount of ytterbium acetate to 0.15 mmol, and setting the microwave digestion temperature at 150°C, NaYF can also be obtained 4 : Yb, Er spherical nanoparticles, such as figure 2 As shown, the fluorescence intensity changes as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com