Surface porous graphene material and preparation method thereof

A surface porous and graphene technology, applied in the field of nanomaterials, can solve the problem of low controllability of nanopore size and surface distribution density, low controllability of ablated pore size and density, and nanoparticle size and density. Uncontrollable load efficiency and other problems, to achieve the effect of uniform surface loaded oxide, short preparation time and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

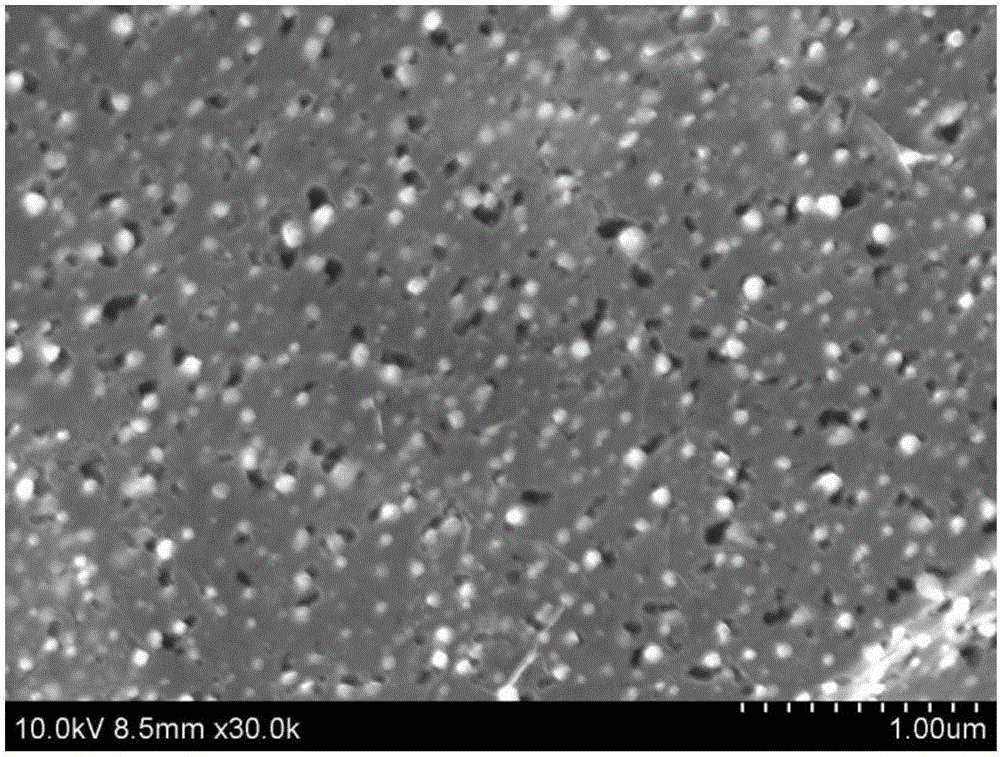

[0031] Disperse 2 mg of graphene oxide in 10 ml of ethanol, sonicate until the solution is evenly dispersed and translucent light brown, add 8 mg of nickel nitrate and stir to dissolve it completely. Add 5 grams of solid carbon dioxide (dry ice) to the above solution, place the above mixture in a 100 ml autoclave, heat and react at 200°C for 0.5 hour while stirring; cool, centrifuge, and dry the reacted solution in an inert Calcining at 800° C. for 1 hour in an atmosphere (nitrogen) to obtain graphene with nanopores on the surface. Such as figure 1 As shown, the pores on the surface of the porous graphene material are evenly distributed, and the nanopore diameters are concentrated in the range of 80-150nm.

Embodiment 2

[0033] Disperse 30 mg of graphene oxide in 20 ml of methanol, sonicate until the solution is uniformly dispersed and translucent light brown, then add 60 mg of copper nitrate and stir. Add 4 grams of solid carbon dioxide (dry ice) to the above solution, place the above mixture in a 100 ml autoclave, heat and react at 170°C for 0.8 hours while stirring; cool, centrifuge, and dry the reacted solution in an inert Calcining at 600° C. for 1 h in an atmosphere (argon gas) to obtain graphene with nanopores on the surface. The pores on the surface of the porous graphene material are evenly distributed, and the diameters of the nanopores are concentrated in the range of 100-200 nm.

Embodiment 3

[0035] Disperse 200 mg of graphene oxide in 40 ml of acetonitrile, sonicate until the solution is uniformly dispersed and translucent light brown, add 100 mg of ferric nitrate and stir to dissolve it completely. Add 5 grams of solid carbon dioxide (dry ice) to the above solution, place the above mixture in a 200 ml autoclave, heat and react at 180° C. for 1 hour while stirring; cool, centrifuge, and dry the reacted solution in an inert Calcining at 900° C. for 0.5 h in an atmosphere (argon gas) to obtain graphene with nanopores on the surface. The pores on the surface of the porous graphene material are evenly distributed, and the diameters of the nanopores are concentrated in the range of 50-100 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com