Polymer-nanometer metal oxide composite ink, and preparation method and application thereof

A nano-metal and oxide technology, applied in applications, inks, household appliances, etc., can solve the problems of increasing the cost of device preparation, difficulty in uniform thin film, low device yield, etc., achieving low film thickness dependence and reducing roughness. , Improve the effect of density and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] Preparation of polymer-nano metal oxide:

[0054] The nanometer metal oxide particle dispersion liquid and the polymer dispersion liquid are mixed through different volume ratios to obtain the polymer-nano metal oxide composite ink. Take ZnO:PEI composite ink as an example: ZnO dispersion liquid and PEI dispersion liquid are mixed according to different volume ratios, and then obtained by ultrasonic dispersion.

[0055] Preparation of polymer-nano metal oxide cathode modification layer:

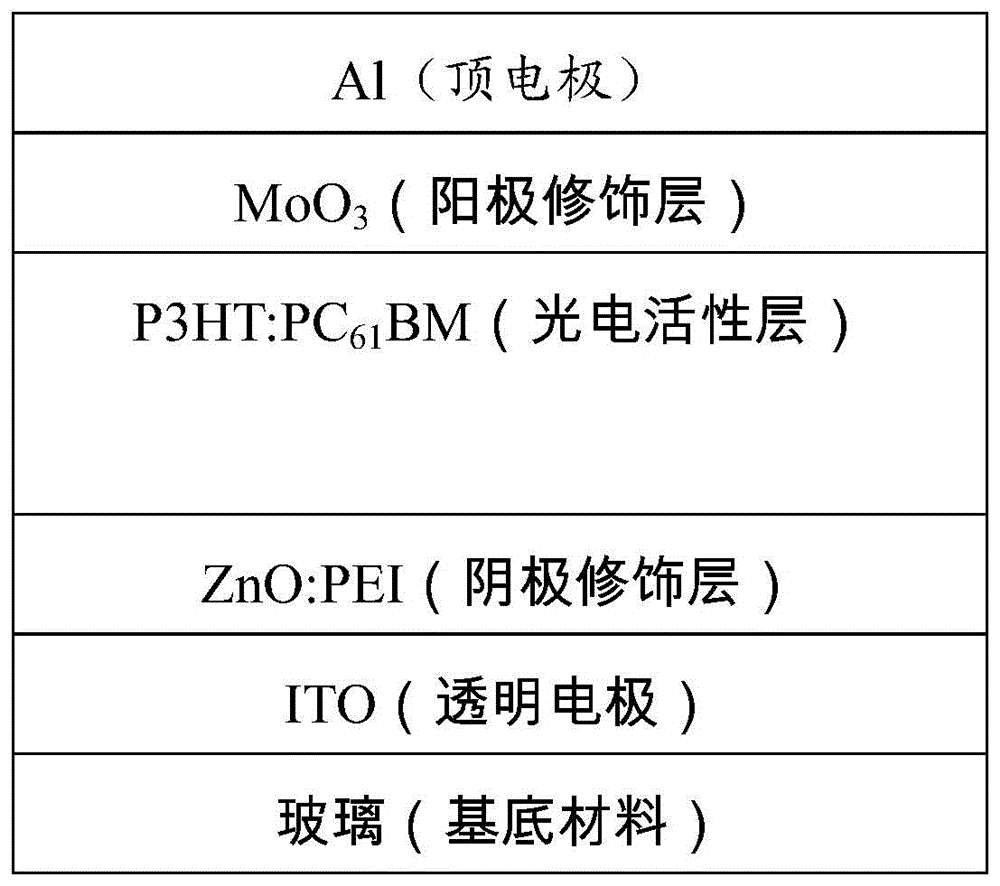

[0056] The polymer-nano metal oxide composite ink can be deposited on the surface of the ITO electrode or the organic photoactive layer by methods such as spin coating and doctor blade coating to obtain a cathode modification layer. In some examples, a composite cathode modification layer is deposited on the surface of the cathode by spin coating in an organic photoelectric device with an inverted structure.

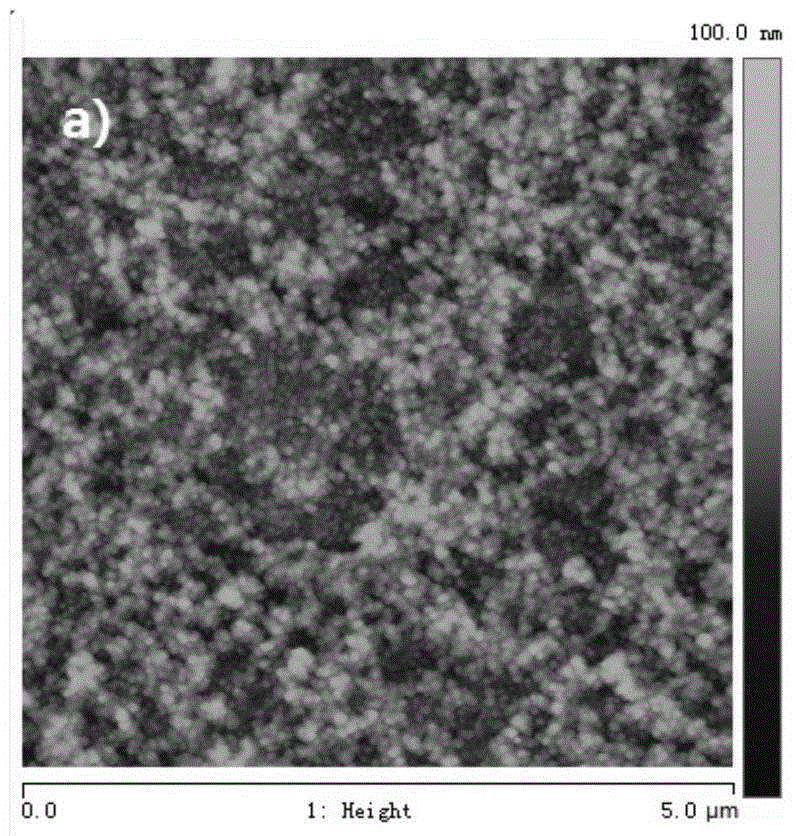

[0057] The nanometer metal oxide-conductive polymer composition prepared b...

Embodiment 1

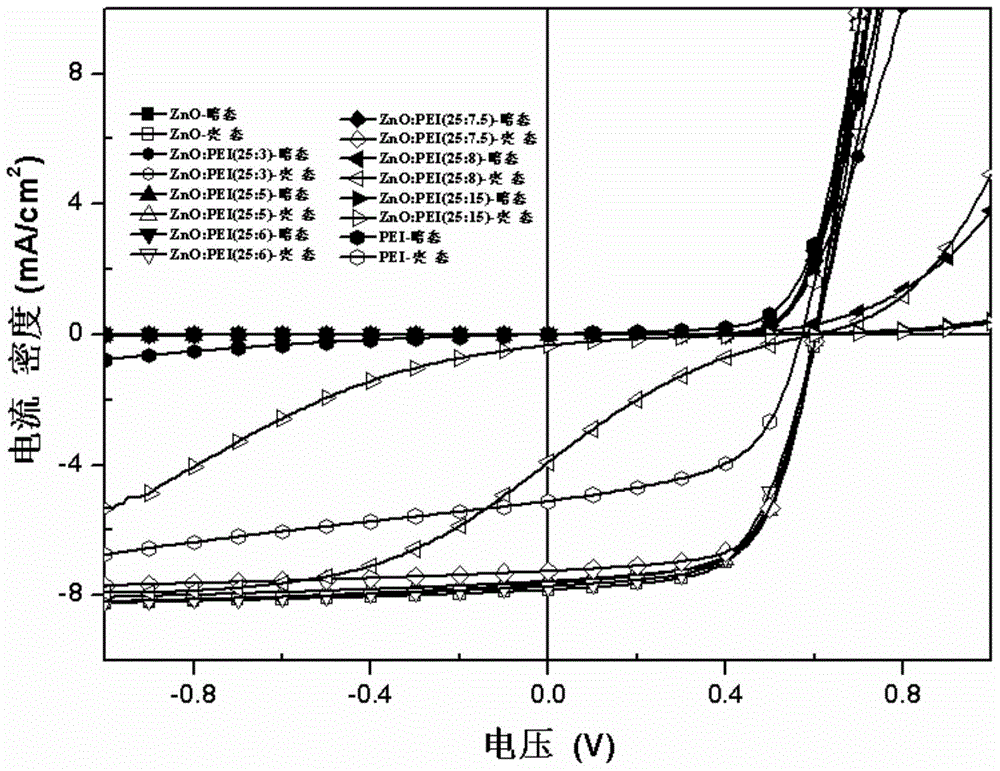

[0059] Example 1ZnO: Preparation of PEI Composite Ink and Application in Organic Photovoltaic Devices

[0060] The specific operating process of the present embodiment is as follows:

[0061] 1. Preparation of ZnO nanoparticles: Take 2.950g of zinc acetate dihydrate, dissolve it in 125mL of anhydrous methanol, heat and stir to 60°C. Take 1.480g of potassium hydroxide, dissolve it in 65mL of anhydrous methanol, ultrasonically dissolve, add the methanol solution of potassium hydroxide to the zinc acetate solution drop by drop, and stir magnetically at 600rpm for 2h under heating at 60-65°C. During the reaction process, the solution was colorless at first, then a white precipitate appeared until the precipitate gradually disappeared, and the solution turned light blue, and a white precipitate appeared after about 2h. Continue heating for 0.5h, stop heating, and the reaction is complete.

[0062] 2. Preparation of ZnO ink: After the preparation of ZnO nanoparticles is completed, ...

Embodiment 2

[0070] The preparation of ZnO:PEIE composite ink: get the solution of the PEIE (80% methoxylated polyethyleneimine) that the concentration is 10mg / ml ZnO ink (its preparation process can refer to embodiment 1) and weight concentration is 0.4% according to Different volume ratios were mixed and ultrasonically dispersed to obtain ZnO:PEIE composite ink.

[0071] Preparation of ZnO:PEIE composite cathode modification layer: the ZnO:PEIE composite cathode modification layer can be obtained by spin-coating on the surface of the ITO electrode at 2300rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com