Preparation method of high-glossiness high-water-permeability polyurethane resin

A polyurethane resin, water-permeable technology, used in polyurea/polyurethane coatings, animal husbandry, chemical treatment of small raw hides/large raw hides/leather hides/furs, etc. To avoid problems such as large dosage of additives, environmental and human health hazards, etc., to achieve the effects of excellent hand feel and anti-wrinkle performance, excellent hydrophilicity, and increased solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

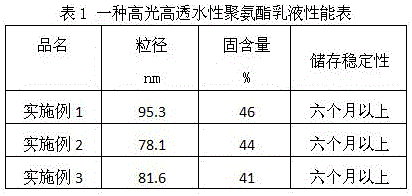

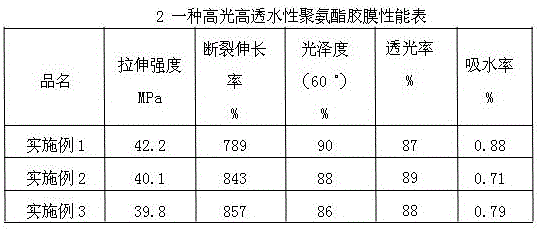

Examples

Embodiment 1

[0018] Embodiment 1 A kind of preparation method of high light and high water permeability polyurethane resin, steps and conditions are as follows: material and mass percentage are as follows:

[0019] Polyol 49.2%, diisocyanate 38.4%, catalyst 0.8%, carboxylic acid type hydrophilic chain extender 2.5%, neutralizer 2.1%, pre-chain extender 4.2%, end-blocking agent 1.7%, post-chain extender 1.1% ;

[0020] The specific addition amount is as follows: the polyol is polybutylene adipate (Mn=2000), the mass is 43.48g; the diisocyanate is isophorone diisocyanate, the mass is 33.9g; the catalyst is organic bismuth, the mass is 0.70g; The carboxylic acid-type hydrophilic chain extender is dimethylolpropionic acid, with a mass of 2.2g; the neutralizer is triethylamine, with a mass of 1.88g; the pre-chain extender is 1,4 butanediol, with a mass of 3.74g; The agent is octadecylamine, quality 1.52g; The post-chain extender is 2-[(2-aminoethyl)amino]sodium ethanesulfonate aqueous solution...

Embodiment 2

[0026] Embodiment 2 A kind of preparation method of high light and high water permeability polyurethane resin, steps and conditions are as follows: material and mass percentage are as follows:

[0027] Polyol 66%, diisocyanate 24.5%, catalyst 1%, carboxylic acid type hydrophilic chain extender 2.6%, neutralizer 1.9%, pre-chain extender 1.1%, end-blocking agent 1.4%, post-chain extender 1.5% ;

[0028] The specific addition amount is as follows: the polyol is polytetrahydrofuran ether diol (Mn=2000), the mass is 50.21g; the polypropylene glycol (Mn=2000), the mass is 20.45g; the diisocyanate is isophorone diisocyanate, the mass is 26.32g; The catalyst is organic bismuth, with a mass of 1.06g; the carboxylic acid type hydrophilic chain extender is dimethylol propionic acid, with a mass of 2.8g; the neutralizer is triethylamine, with a mass of 2.11g; the pre-chain extender is 1,4 butyl Diol, quality 1.22g; End-capping agent is octadecylamine, quality 1.51g; Post-chain extender i...

Embodiment 3

[0034] Example 3 A preparation method of high-gloss and high-water-permeability polyurethane resin, the steps and conditions are as follows: materials and mass percentages are as follows: polyol 57.8%, diisocyanate 29%, catalyst 0.9%, carboxylic acid type hydrophilic chain extender 3.1% , neutralizer 2.3%, pre-chain extender 3%, end-capping agent 2.2%, post-chain extender 1.7%

[0035] The specific addition amount is as follows: the polyol is polytetrahydrofuran ether diol (Mn=2000), the mass is 53.83g; the diisocyanate is isophorone diisocyanate, the mass is 27g;

[0036] The catalyst is organic bismuth, with a mass of 0.83g; the carboxylic acid type hydrophilic chain extender is dimethylolpropionic acid, with a mass of 2.9g; the neutralizer is triethylamine, with a mass of 2.18g; the pre-chain extender is 1,4 Butanediol, quality 2.83g; End-capping agent is octadecylamine, quality 2.1g; Post-chain extender is the 2-[(2-aminoethyl)amino] sodium ethanesulfonate aqueous solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com