Preparation method for NiCo2S4@NiCo2O4 nanoneedle composite catalytic electrode with core-shell structure

A technology of catalytic electrode and core-shell structure, which is applied in the field of electrocatalysis, can solve the problems of unfavorable electrocatalytic performance, poor stability and electronic conductivity, unfavorable commercial application, etc., and achieve favorable electrocatalytic performance and high stability and electron conductivity, the effect of low electrode cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

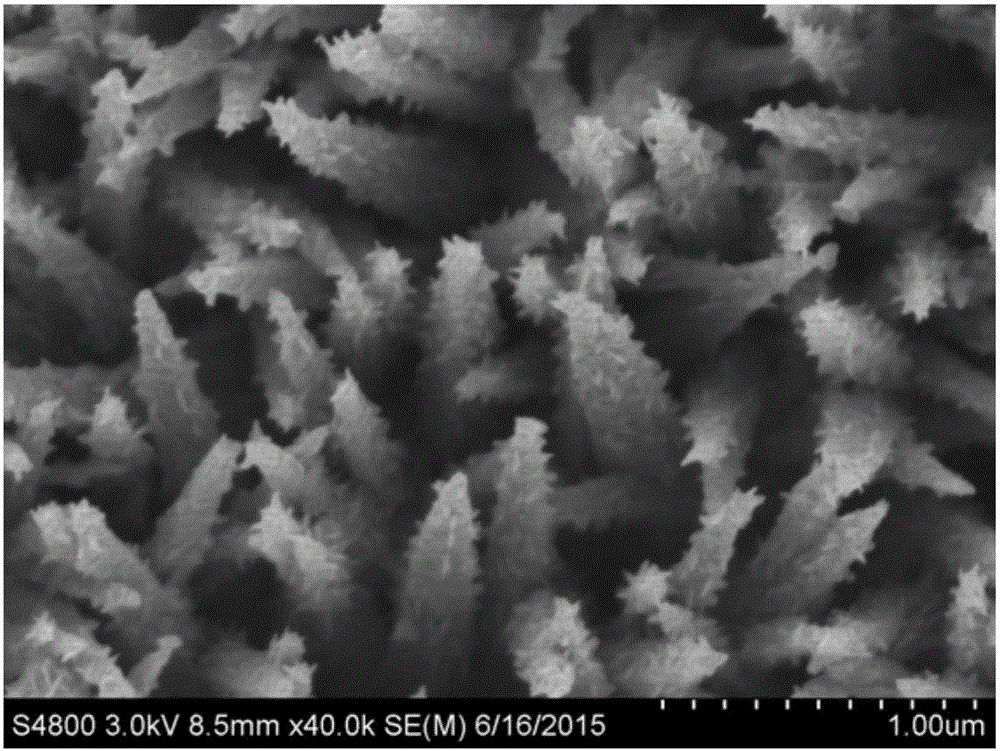

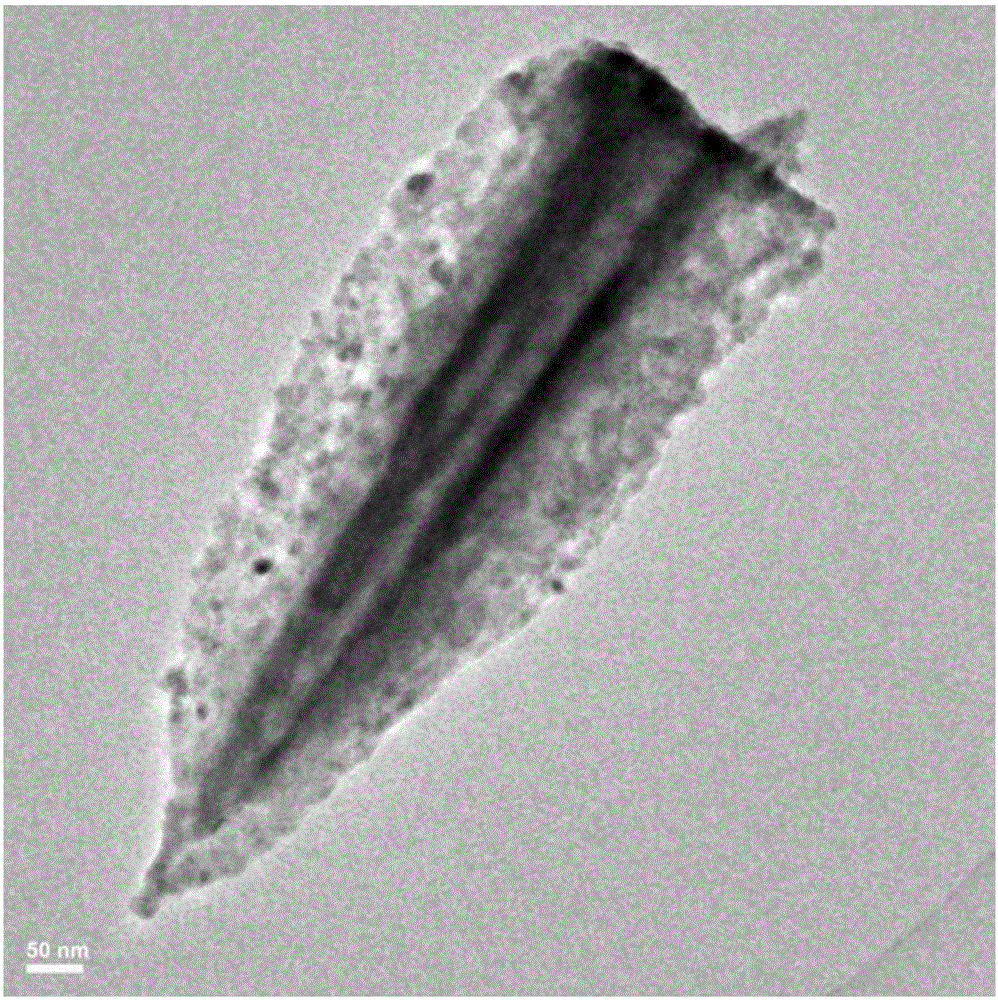

[0028] Wash the 4cm×1cm nickel foil with acetone, ethanol, and distilled water successively, and ultrasonically clean each for 15min until the surface is clean, then blow dry with nitrogen gas for use. Weigh 0.1426g NiCl 2 ·6H 2 O, 0.2852g CoCl 2 ·6H 2O and 0.4324g urea (the molar ratio is 1:2:12); they are dissolved in the mixed solution of 24mL water and ethanol (the volume ratio is 1:1); Transfer to a 30mL reactor and place in an oven at 95°C for 10h. After the reaction, the reactor was cooled to room temperature, and the Ni-Co composite precursor was taken out, washed with distilled water and ethanol in turn, and dried in a vacuum oven at 60° C. for 2 hours. Transfer 22.5mL of sodium sulfide solution (concentration 0.1-0.4mol / L) to a 30mL reactor, put the prepared Ni-Co composite precursor into the reactor, and place it in an oven at 120°C for vulcanization reaction, keeping 4-16h. After the vulcanization reaction is over, wait for the reactor to cool down to room te...

Embodiment 2

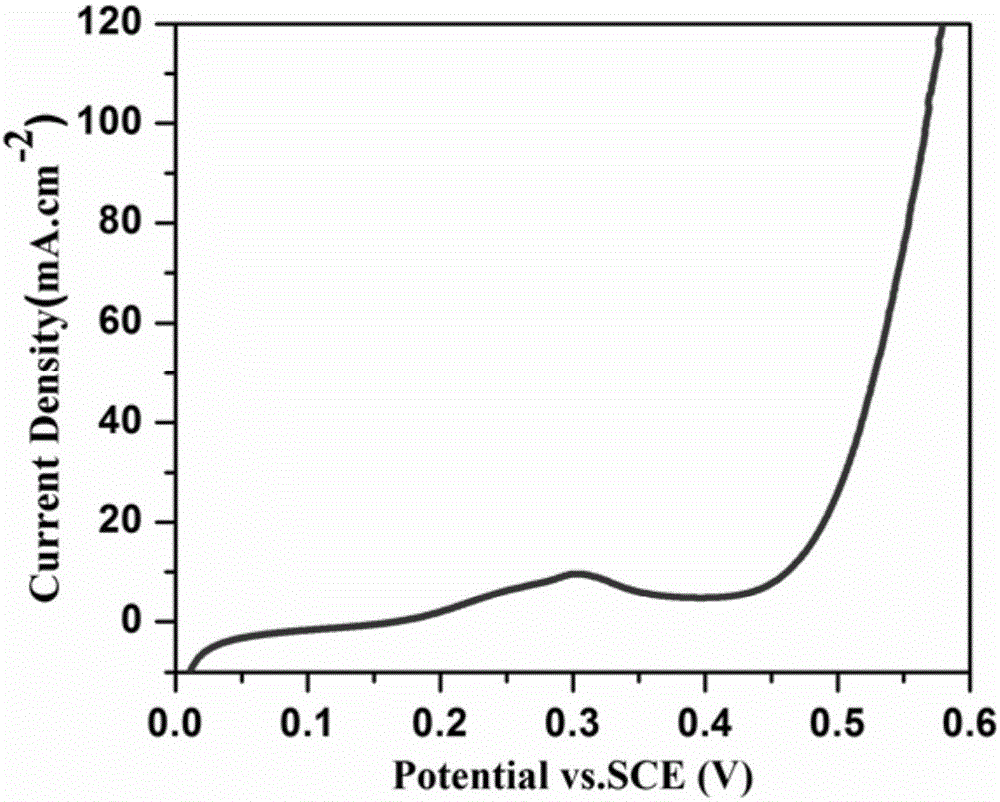

[0030] NiCo is prepared in Example 1 2 S 4 @NiCo 2 o 4 The electrochemical properties of the nanoneedle composite catalytic electrode were tested in 1M KOH solution.

[0031] Using a three-electrode electrochemical measurement system, on the CHI660c electrochemical workstation, the prepared NiCo 2 S 4 @NiCo 2 o 4 The nanoneedle composite catalytic electrode is the working electrode, the platinum wire electrode is the counter electrode, and the saturated calomel electrode (SCE) is the reference electrode. The linear sweep voltammetry curve (LSV) of the measurement electrode is shown in image 3 . The specific test conditions are as follows: the electrolyte is 1mol L -1 KOH solution; the potential window is 0-0.8V; the scan rate is 0.005V / s. from image 3 It can be seen in the synthesized NiCo 2 S 4 @NiCo 2 o 4 The nanoneedle composite catalytic electrode shows good catalytic performance in the process of water oxidation, and the current density has reached 120mA c...

Embodiment 3

[0033] NiCo is prepared in Example 1 2 S 4 @NiCo 2 o 4 Nanoneedle composite catalytic electrode at 1mol L -1 The stability of the electrode during water oxidation was tested in KOH solution.

[0034] Using a three-electrode electrochemical measurement system, on a CHI660c electrochemical workstation, the prepared core-shell structure NiCo 2 S 4 @NiCo 2 o 4 The nanoneedle composite catalytic electrode is the working electrode, the platinum wire electrode is the counter electrode, and the saturated calomel electrode (SCE) is the reference electrode. The stability of the electrode is measured by a multi-step current method, see Figure 4 . The specific test conditions are as follows: the electrolyte is 1mol L -1 KOH solution; the current value setting range is 0.005-0.05A, the current interval of each step is 0.005A, and the holding time of each step is 500s. from Figure 4 It can be seen that within about 1.5h, the catalytic performance of the catalyst is basically no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com