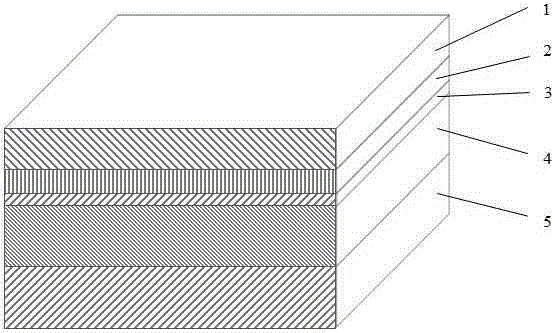

Preparation method for WS<2>/Si heterojunction solar cell

A solar cell and heterojunction technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems that cannot be separated from the preparation process of new semiconductor materials, affect the large-scale popularization and application, and the efficiency is close to the theoretical limit. Application prospect, high crystallization performance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

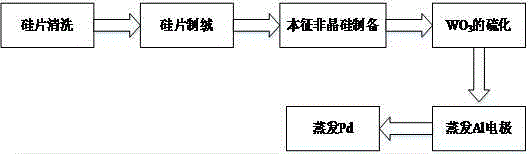

[0030] WS of the present invention 2 / Si heterojunction solar cell preparation method, comprising the following steps:

[0031] (1) Use acetone solution to ultrasonically clean the single crystal silicon wafer to remove organic dirt on the surface of the silicon wafer, and use alcohol to carry out ultrasonic cleaning to the silicon wafer to remove the acetone on the surface of the silicon wafer, and rinse with deionized water for 3 times . Among them, the thickness of monocrystalline silicon wafer is 150 microns to 300 microns, and the resistivity is 0.2Ω•㎝~1.0Ω•㎝.

[0032] (2) Using NH 4 F. Clean the above-mentioned silicon wafer with HF mixed solution at room temperature to remove the surface oxide layer, and then rinse it in deionized water. The ammonium fluoride solution has a concentration of 35 wt% to 45 wt%, and the hydrofluoric acid solution has a concentration of 45 wt% to 55 wt%. The cleaned single crystal silicon wafer is designated as single crystal silicon waf...

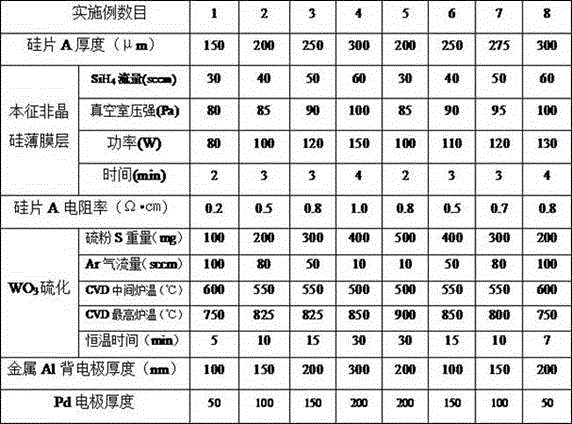

example 1

[0044] (1) Complete the basic etching and cleaning of the monocrystalline silicon wafer according to the above scheme. Among them, the thickness of the silicon wafer is 150 μm, and the resistivity is 0.2 Ω•cm.

[0045] (2) SiH is introduced into the PECVD system 4 , flow 30 sccm, pressure 80 Pa, time 2 min, power 80W.

[0046] (3) Place the quartz boat filled with sulfur powder S (100mg) in the low-temperature area upstream of the vent of the quartz tube of the heating furnace at a temperature of 250°C. WO 3 Place the silicon wafer in the center of the furnace, fill the quartz tube with protective gas Ar for 10 min to exhaust the air, and then heat the quartz tube to 600 °C. The Ar gas flow is 100 sccm.

[0047] (4) Keep the above-mentioned Ar gas flow constant, slowly heat the quartz tube to 750°C at 3°C / min, keep the temperature constant for 5 minutes, and then cool to room temperature.

[0048] (5) Thermally evaporated Al electrodes on the back of the silicon wafer wi...

example 2

[0051] (1) Complete the etching and cleaning of the monocrystalline silicon wafer according to the above scheme. Among them, the thickness of the silicon wafer is 200 μm, and the resistivity is 0.5 Ω•cm.

[0052] (2) SiH is introduced into the PECVD system 4 , flow 40 sccm, pressure 85 Pa, time 3 min, power 100W.

[0053] (3) Place the quartz boat filled with sulfur powder S (200mg) in the low-temperature area upstream of the vent of the quartz tube of the heating furnace at a temperature of 230°C. WO 3 Place the silicon wafer in the center of the furnace, fill the quartz tube with protective gas Ar for 15 min to exhaust the air, and then heat the quartz tube to 550 °C. The Ar gas flow rate is 80 sccm.

[0054] (4) Keep the above-mentioned Ar gas flow constant, slowly heat the quartz tube to 825 °C at ~5 °C / min, keep the temperature for 10 min, and then cool to room temperature.

[0055] (5) Thermally evaporated Al electrodes on the back of the silicon wafer with tungste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com