Preparation method of irradiation-resistant glass fiber air filter paper

A technology of glass fiber and air filter paper, applied in the field of nuclear power, can solve the problems of poor radiation resistance and achieve the effects of increasing radiation resistance, wide application range, and enhancing hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

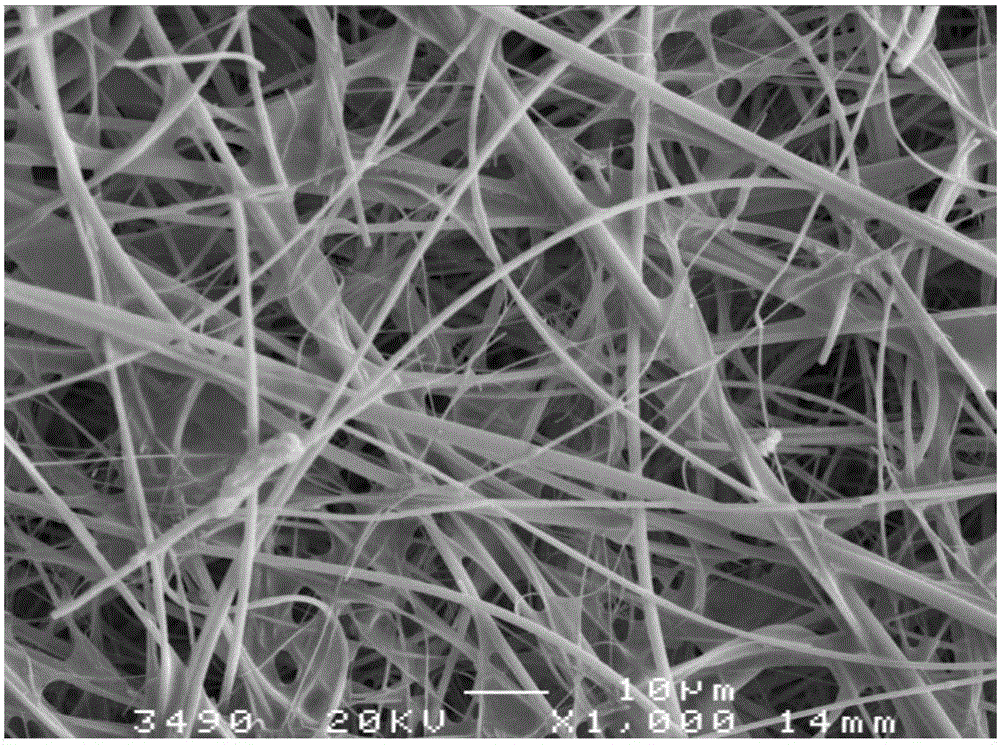

Image

Examples

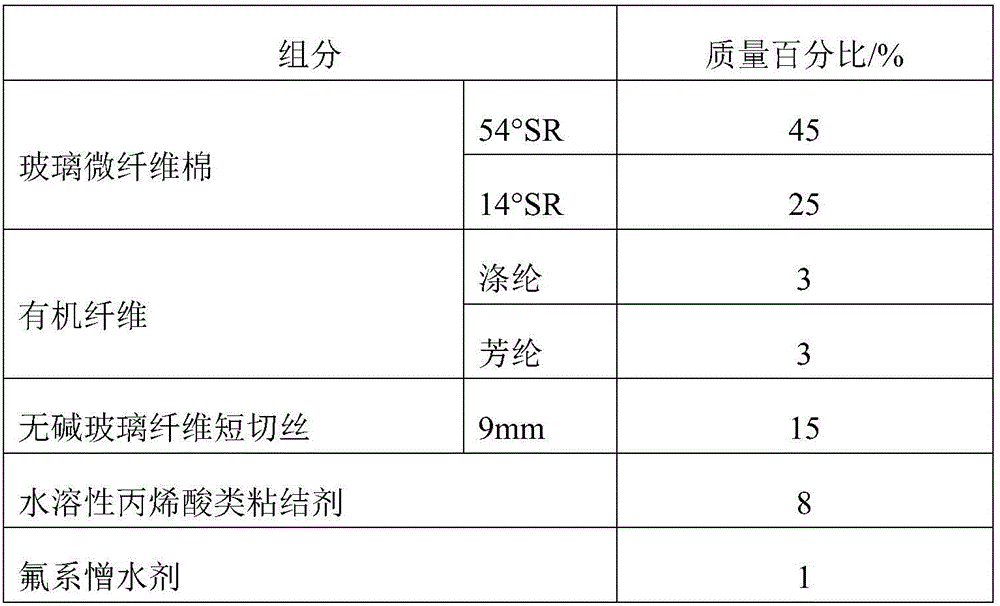

Embodiment 1

[0026] Radiation-resistant glass fiber air filter paper uses two kinds of glass microfiber cotton as the main raw material, 0.7d (fineness) × 6mm (length) polyester, aramid fiber, 7μm (diameter) × 9mm (length) non-alkali glass fiber Chopped shreds, adding water and hydrochloric acid (mass concentration is 10%), stirred by a high-frequency deflagger to make a pulp suspension with a concentration of 0.9wt% and a pH value of 2.5, and diluted to a concentration of less than 0.2 after passing through the slag removal system The pulp suspension of wt% is sent to the wire head box, forms wet paper sheet by Fourdrinier machine, sprays S560 acrylic binder (produced by BASF) and TG-5521 fluorine water-repellent agent (large size) evenly on the wet paper sheet Gold company), dried at 160°C for 30 minutes to form radiation-resistant glass fiber air filter paper.

[0027] The above two glass microfiber wools are composed of the following components by mass: SiO 2 : 59%, Al 2 o 3 : 13%, ...

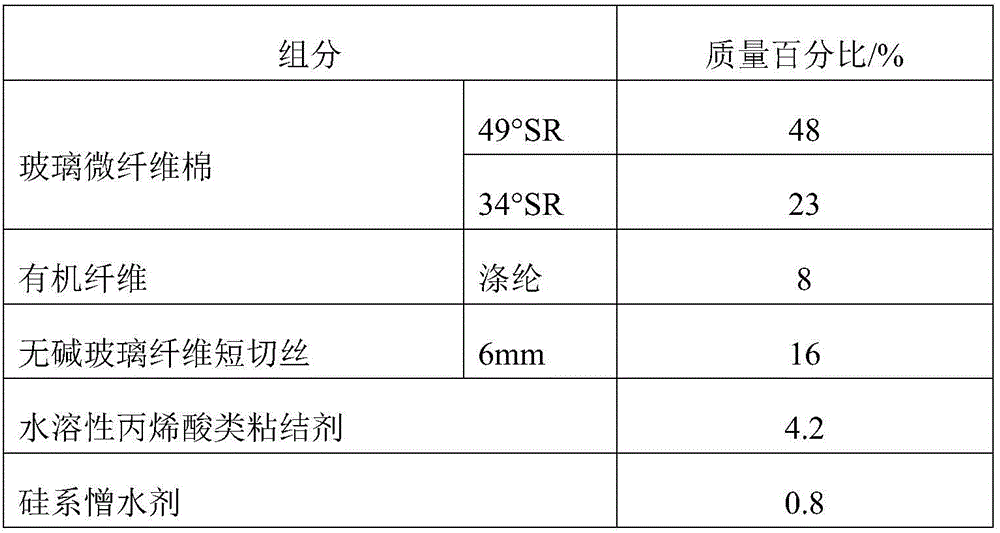

Embodiment 2

[0036] Radiation-resistant glass fiber air filter paper uses two kinds of glass microfiber cotton as the main raw materials, 2d × 9mm polyester fiber, 5 μm × 6mm alkali-free glass fiber chopped shreds, water and sulfuric acid (mass concentration 15%), after high frequency The deflaking machine stirs evenly to make a pulp suspension with a concentration of 1.0wt% and a pH value of 2. After passing through the slag removal system, it is diluted to a pulp suspension with a concentration of less than 0.2wt%, and sent to the head box, and formed by a fourdrinier machine. On the paper sheet, apply 26084 acrylic adhesive (produced by Lubrizol) and IE-6683 silicon-based water repellent (produced by Dow Corning) evenly on the wet paper, and dry at 200°C for 40min to form radiation-resistant Fiberglass air filter paper.

[0037] The above two glass microfiber wools are composed of the following components by mass: SiO2 : 61%, Al 2 o 3 : 11%, CaO: 6%, MgO: 2%, BaO: 3%, ZnO: 2%, K 2 O:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com