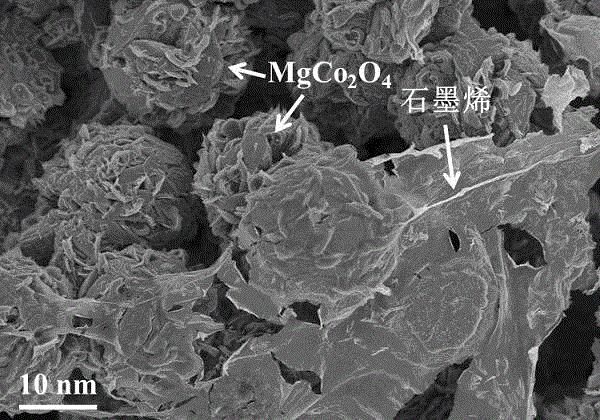

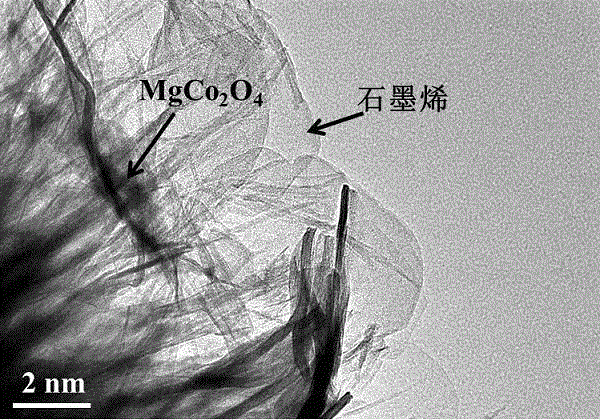

Magnesium-cobalt oxide/graphene composite material used as supercapacitor electrode material and preparation method thereof

A technology of supercapacitor and cobalt oxide, applied in the field of electrochemical energy, can solve the problems of low electric capacity of electric double layer capacitor electrode material, poor cycle stability and rate of goose capacitance, etc., achieve low cost, improve total capacitance, Penetration-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

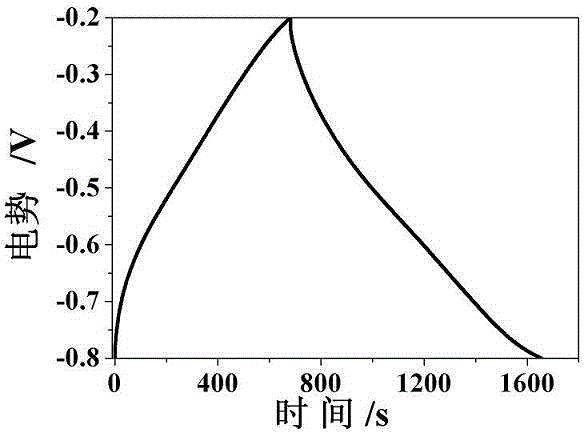

Method used

Image

Examples

Embodiment 1

[0027] The first step: 1) Graphene oxide was prepared by the Hume method using graphite as raw material, and the graphene oxide after pickling, alcohol washing, and drying was ground, and ultrasonically dispersed in deionized water to obtain a concentration of 2 mg / mL graphene oxide aqueous dispersion; 2) Weigh 190 mg (0.80 mmol) NiCl 2 ·6H 2 O, dispersed in 20 mL of the graphene oxide water dispersion obtained in 1), diluted with water to 80 mL, stirred evenly to fully dissolve; 3) After successive centrifugation, precipitation, deionized water washing, and drying, nickel ion modified modified graphene oxide, which was ground and dispersed in deionized water to obtain a 2 mg / mL modified graphene oxide solution.

[0028] The second step: the molar ratio of 2:1 Co(CH 3 COO) 2 4H 2 O and Mg(CH 3 COO) 2 4H 2 O was dissolved in dilute nitric acid to make 80 mL of Co 2+ and Mg 2+For a solution with a total concentration of 0.015 mol / L, 25 wt% ammonia water was added as an...

Embodiment 2

[0030] The first step: 1) Graphene oxide was prepared by the Hume method using graphite as raw material, and the graphene oxide after pickling, alcohol washing, and drying was ground, and ultrasonically dispersed in deionized water to obtain a concentration of 2 mg / mL graphene oxide aqueous dispersion; 2) Weigh 136 mg (0.80 mmol) CuCl 2 2H 2 O, dispersed in 20 mL of the graphene oxide aqueous dispersion obtained in 1), diluted with water to 80 mL, stirred evenly to fully dissolve; 3) successively centrifuged, precipitated, washed with deionized water, and dried to obtain the modified copper ion modified graphene oxide, which was ground and dispersed in deionized water to obtain a 2 mg / mL modified graphene oxide solution.

[0031] The second step: the molar ratio of 2:1 Co(CH 3 COO) 2 4H 2 O and Mg(CH 3 COO) 2 4H 2 O was dissolved in dilute nitric acid to make 80 mL of Co 2+ and Mg 2+ For a solution with a total concentration of 0.05 mol / L, use 25 wt% ammonia water as...

Embodiment 3

[0033] The first step: 1) Graphene oxide was prepared by the Hume method using graphite as raw material, and the graphene oxide after pickling, alcohol washing, and drying was ground, and ultrasonically dispersed in deionized water to obtain a concentration of 2 mg / mL graphene oxide aqueous dispersion; 2) Weigh 190 mg (0.80 mmol) CoCl 2 ·6H 2 O, dispersed in 20 mL of the graphene oxide aqueous dispersion obtained in 1), diluted with water to 80 mL, stirred evenly to fully dissolve; 3) After successive centrifugation, precipitation, deionized water washing, and drying, the cobalt ion modified The modified graphene oxide was finely ground and dispersed in deionized water to obtain a 2 mg / mL modified graphene oxide solution.

[0034] The second step: the molar ratio of 2:1 Co(CH 3 COO) 2 4H 2 O and Mg(CH 3 COO) 2 4H 2 O was dissolved in dilute nitric acid to make 80 mL Co 2+ and Mg 2+ For a solution with a total concentration of 0.10 mol / L, use 25 wt% ammonia water as a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific capacitance value | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com