Method for removing valence electrons of graphene

A technology of valence electrons and graphene, which is applied in the field of graphene devalence electrons, can solve the problems of undisclosed graphene devalence electron technology, high chemical stability of graphene, difficulty in graphene application, etc., so as to change the characteristics of mutual attraction , easy industrial amplification, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

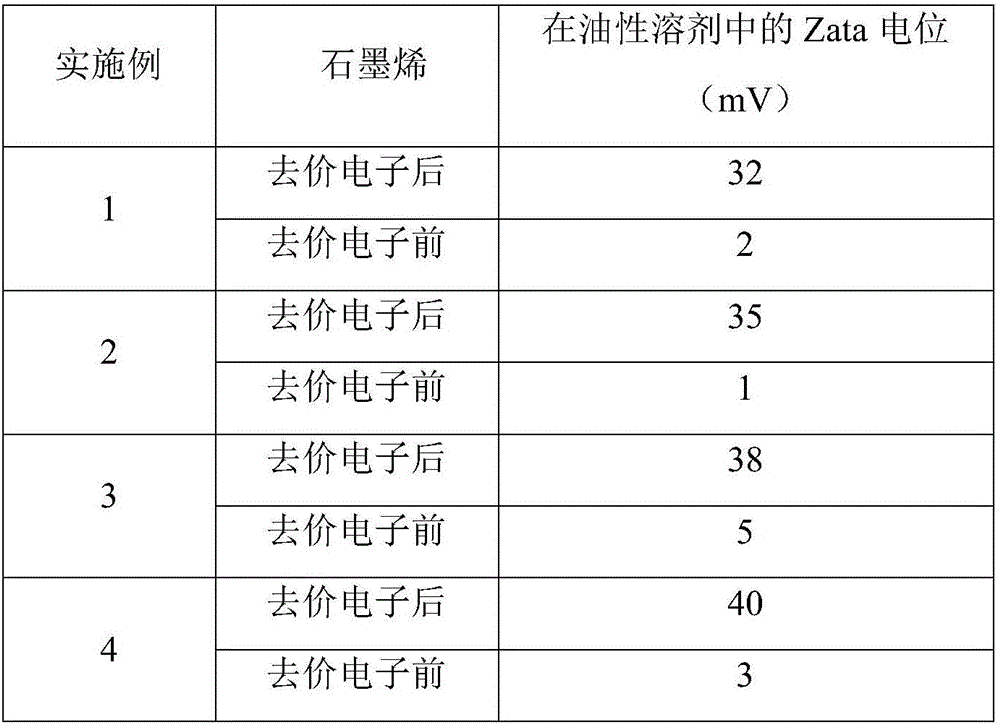

Examples

Embodiment 1

[0023] Graphene oxide, PEG, urea, and sodium sulfide were sequentially added to ether solvent (graphene oxide: PEG: urea: sodium sulfide: ether = 100g: 4g: 5g: 3g: 2L), ultrasonicated for 2 hours, and the mixed solution was placed in In the fume hood, the graphene / valence electron remover mixture is obtained after the solvent is volatilized. The obtained graphene / valence electron remover mixture is placed in carbon dioxide / water vapor (flow 200ml / min) / argon (flow is 200ml / min) atmosphere, after activating 100min at a temperature of 800°C, stop heating, and The gas flow was switched to diborane, and the reaction was carried out at 200° C. for 15 hours. Finally, the temperature was naturally lowered to room temperature under a mixed atmosphere of argon (flow rate: 200 ml / min), and devalent electron graphene was obtained.

Embodiment 2

[0025] Graphene oxide, 12-potassium tungstophosphate, and phosphoric acid were dissolved in deionized water (graphene oxide: 12-potassium tungstophosphate: phosphoric acid: water=100g: 3g: 5g: 2L), ultrasonically stirred for 1 hour, and centrifuged to obtain The graphene / valence electron remover mixture is placed under the atmosphere of carbon dioxide / water vapor (flow rate 200ml / min) / argon gas (flow rate is 200ml / min), after activation at a temperature of 500°C for 120min, stop heating and switch the gas flow Borane was reacted at 180°C for 12 hours, and finally the temperature was naturally lowered to room temperature under the mixed atmosphere of argon (flow rate: 200ml / min) to obtain devalent electron graphene.

Embodiment 3

[0027] Dissolve graphene oxide, polymethyl methacrylate, siloxane, sodium hydrosulfide, and triphenylphosphine in a mixed solution of cyclohexane and methylpyrrolidone (graphene: polymethyl methacrylate: silicon oxide alkane: sodium hydrosulfide: triphenylphosphine: cyclohexane and methylpyrrolidone mixed solution=100g: 4g: 5g: 3g: 2g: 2L), ultrasonic stirring for 1.5 hours, solvent removal, the obtained graphene / valent Electron remover mixture is placed in carbon dioxide / water vapor (flow rate 200ml / min) / argon (flow rate is 200ml / min) atmosphere, after activation at 750°C for 120min, stop heating, switch the gas flow to propborane, The reaction was carried out at 150°C for 24 hours, and finally the temperature was naturally lowered to room temperature in a mixed atmosphere of argon (flow rate: 200ml / min), and devalent electron graphene was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com