Foamed ceramic microspheres with core-shell structure and its preparation method and application

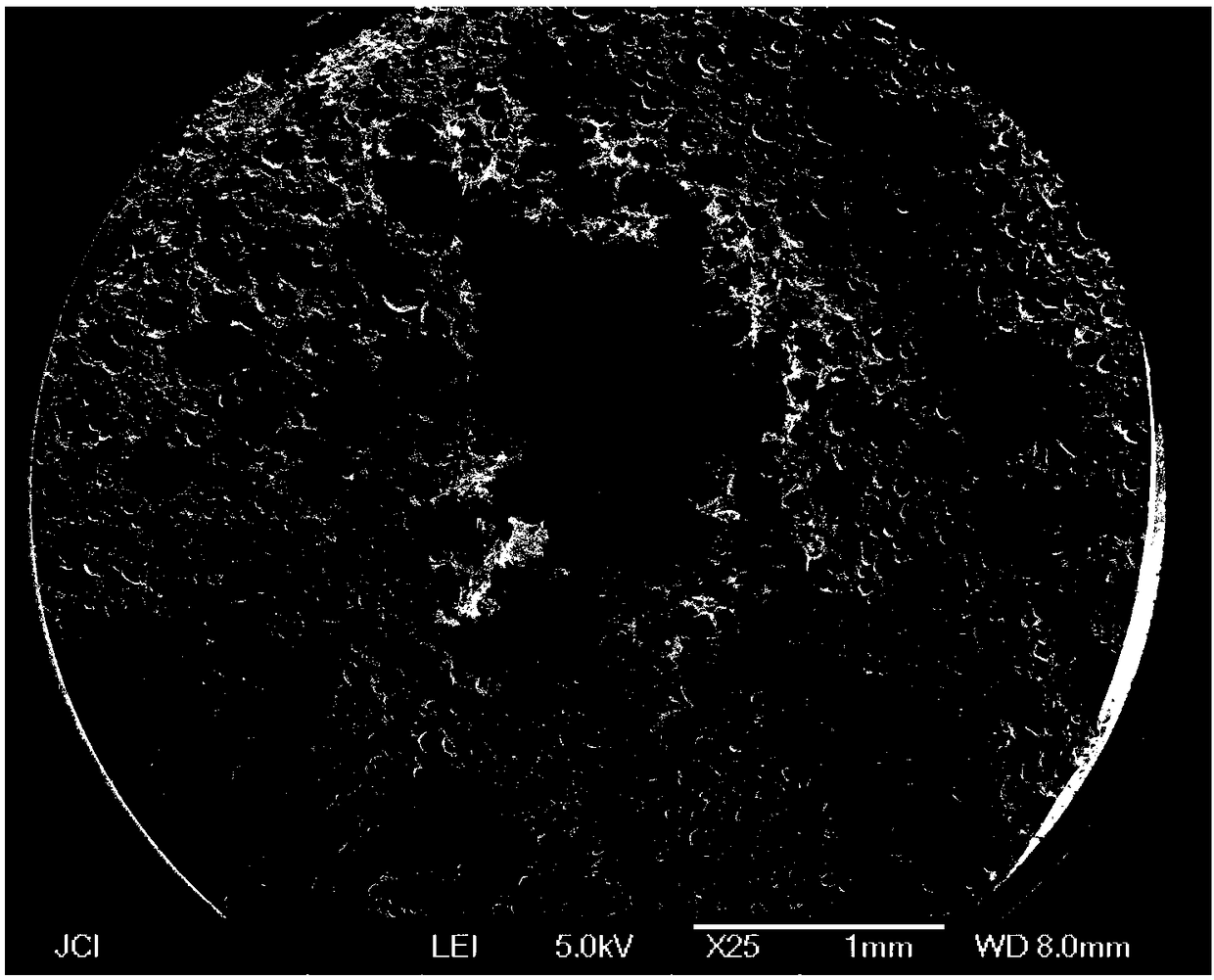

A technology of foam ceramics and core-shell structure, applied in the field of ceramic materials, can solve the problems of limited preparation methods, insufficient foaming, low porosity, etc., and achieve the effects of controllable and consistent growth, complete reaction, and good sound absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

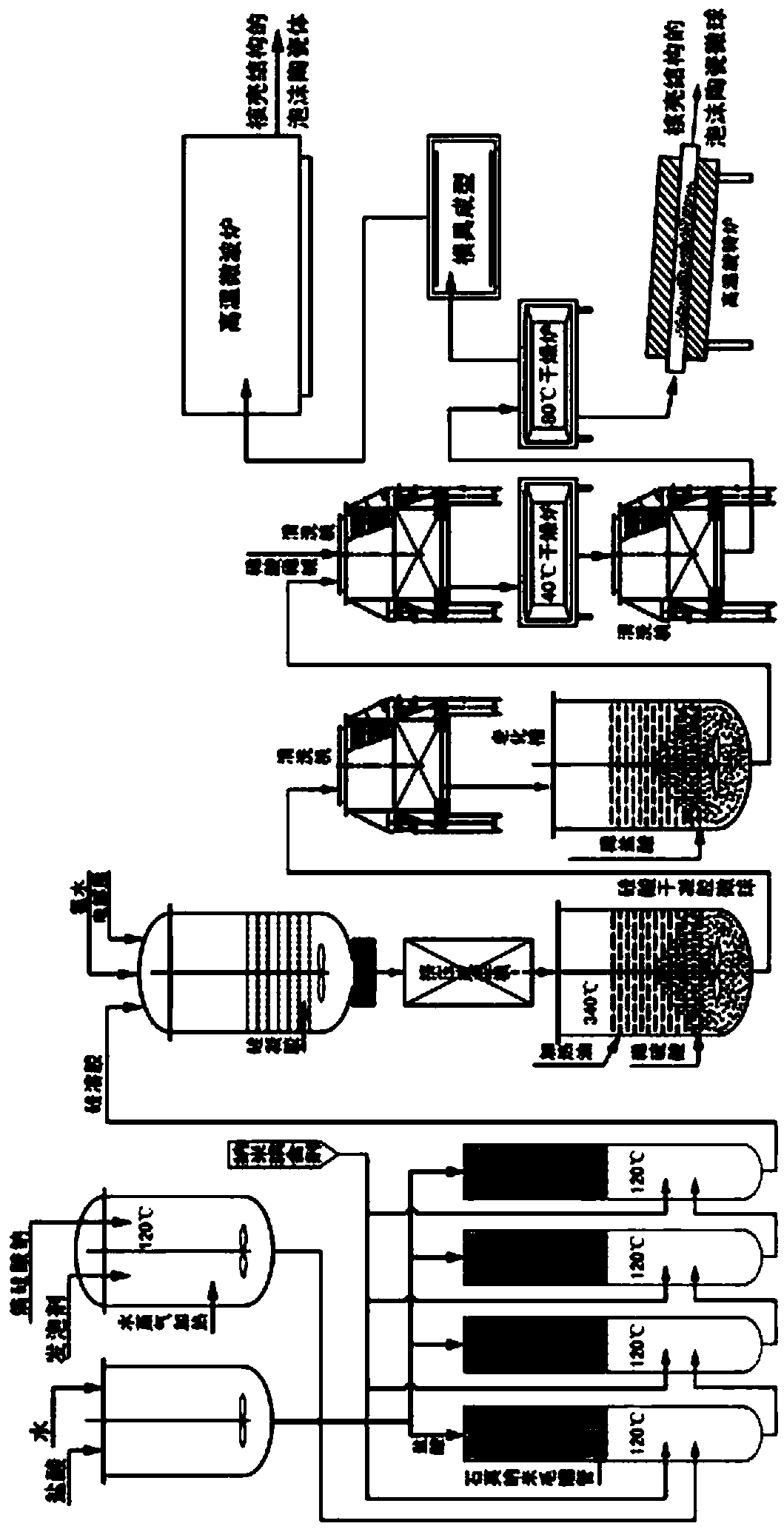

Method used

Image

Examples

preparation example Construction

[0054] The preparation method of foamed ceramic microspheres with a core-shell structure of the present invention: comprising silica sol configuration, silica sol gelation, preparation of silicic acid xerogel microspheres, water washing-surface aging treatment, re-washing and drying, and high-temperature foaming processes , the specific preparation steps are as follows:

[0055] (a) Silica sol configuration: mix sodium metasilicate solution with styrene copolymer to obtain a mixed solution, heat and pressurize; in the reaction process, it is carried out in four stages: the first stage, dilute hydrochloric acid is passed through the hollow In the second stage, when the diameter of the sol particles in the first stage grows to be greater than 30nm, continue to dilute Hydrochloric acid is poured / dropped into the mixed solution through a hollow quartz capillary, and organic platinum is added again to control the pH value of the mixed solution to 9-10; in the third stage, when the ...

Embodiment 1

[0065] (a) Preparation of raw and auxiliary materials:

[0066] The configuration of dilute hydrochloric acid: water, concentrated hydrochloric acid are dropped into the batching tank in proportion to be made into the dilute hydrochloric acid solution of 5% (mass fraction), standby;

[0067] The configuration of the mixed solution: Put the big bag of solid sodium metasilicate (modulus 3.2) into the dissolution kettle, and at a temperature of 120°C, mix it with water to form a 40% (mass fraction) sodium metasilicate aqueous solution, and then add the solid metasilicate The foaming agent styrene-maleic anhydride copolymer with 8% mass of sodium silicate is configured as a mixed solution.

[0068] Silica sol configuration: Put the mixed solution prepared in the previous step into a high-pressure reactor with a pressure of 3 atmospheres, heat the mixed solution to 120°C, and then carry out the reaction in four stages: In the first stage, pass dilute hydrochloric acid through the i...

Embodiment 2

[0075] (a) configuration of dilute hydrochloric acid: water and concentrated hydrochloric acid are dropped into the batching tank in proportion to be made into 10% (mass fraction) dilute hydrochloric acid solution, for subsequent use;

[0076] The configuration of the mixed solution: Put the big bag of solid sodium metasilicate (modulus 2.7) into the dissolution kettle, and at a temperature of 120°C, mix it with water to form a 25% (mass fraction) sodium metasilicate aqueous solution, and then add the solid metasilicate Sodium silicate 5% mass % styrene-maleic anhydride copolymer is configured as a mixed solution.

[0077] Silica sol configuration: put the mixed solution prepared in the previous step into a high-pressure reaction kettle with 4 atmospheres, heat the mixed solution to 100°C, and then carry out the reaction in four stages: the first stage, pass dilute hydrochloric acid through the inner space A quartz capillary with a diameter of 500nm is poured / dropped into the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com