The preparation method of deflazacort

A technology of defluket and organic solvent, which is applied in the field of preparation of steroid hormone drugs, can solve the problems of the increase of production cost and market price of deflukete, the increase of production cost of saponin and mold removal, the increase of planting cost, and the like. High product yield, favorable for industrial production and short synthesis route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

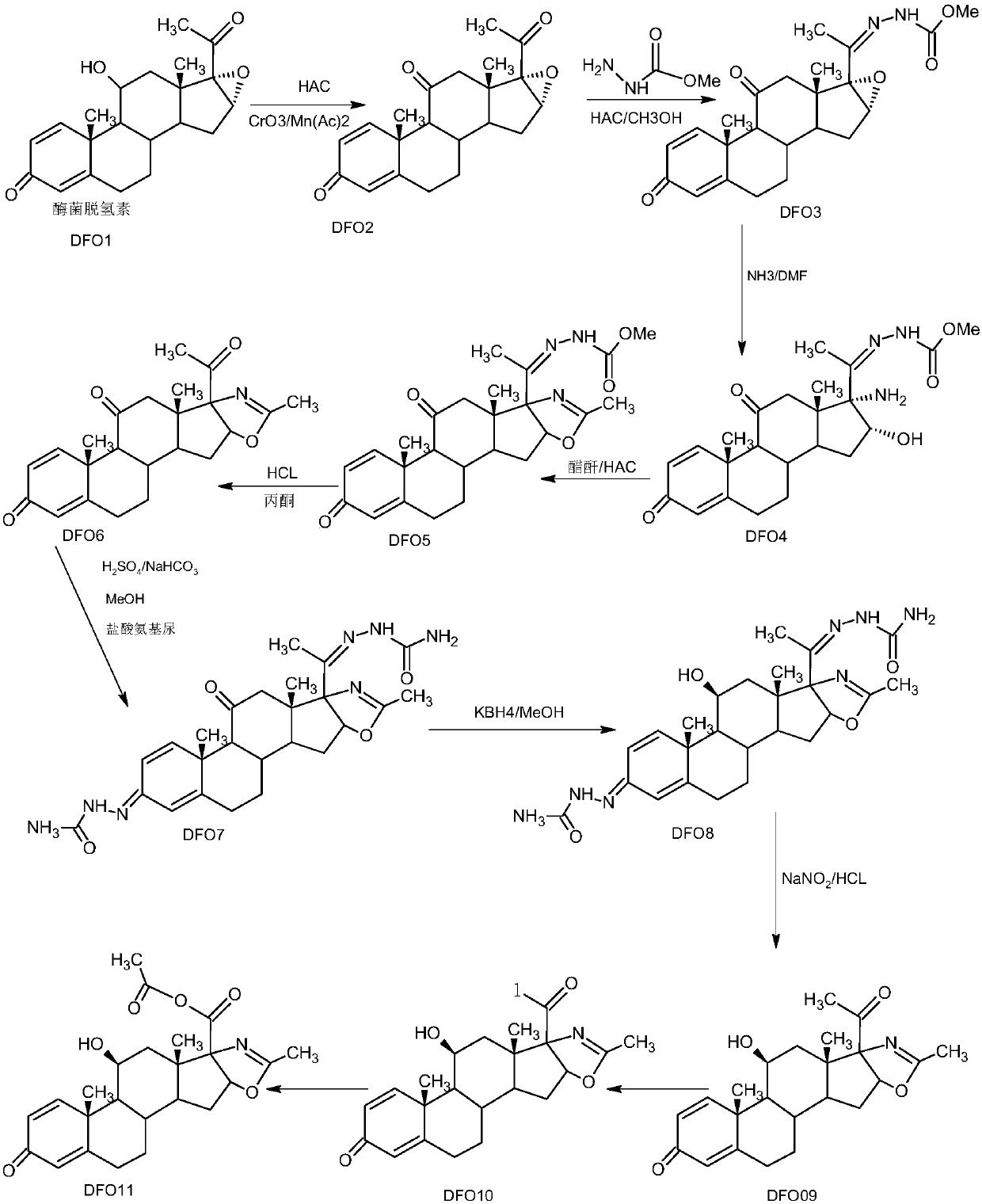

Method used

Image

Examples

Embodiment 1

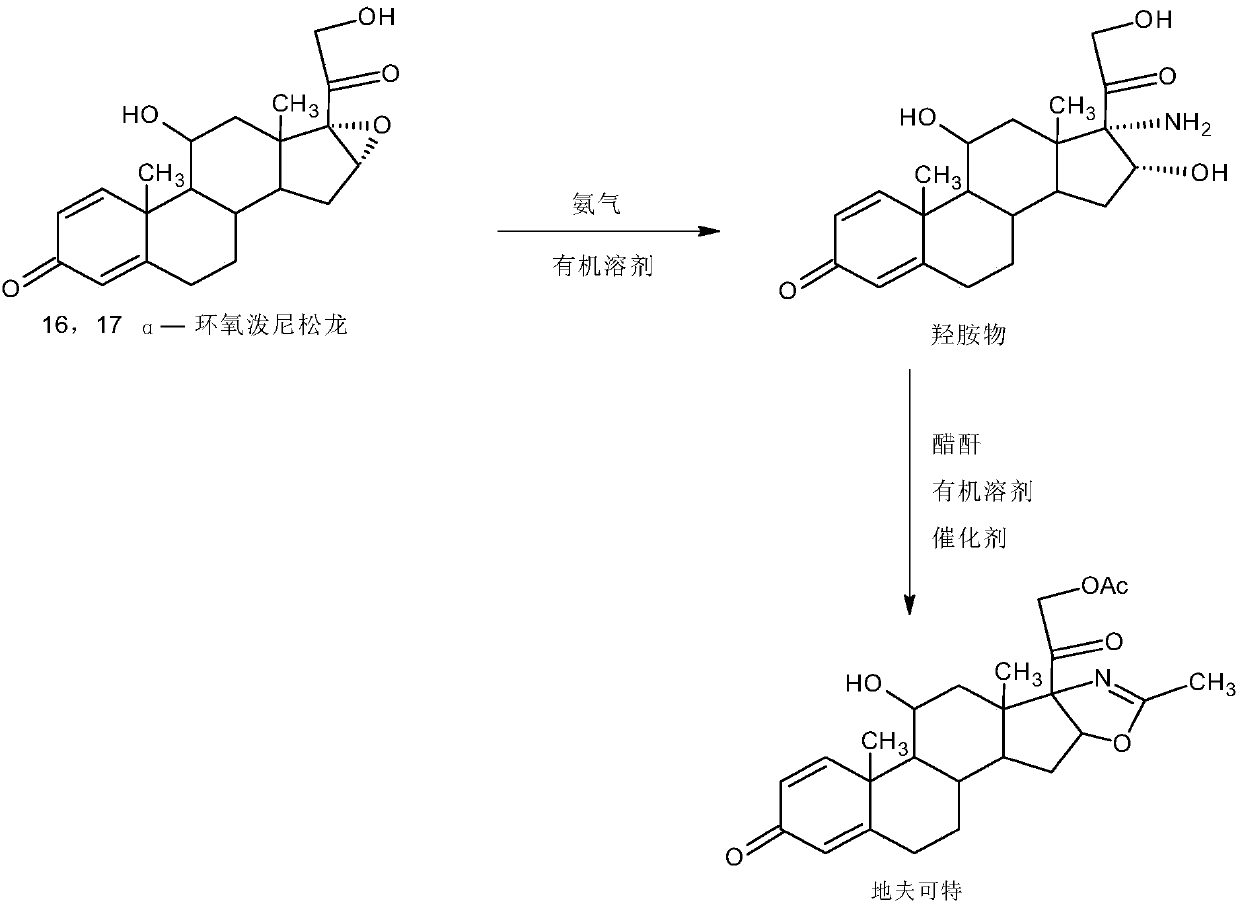

[0019] A: Preparation of hydroxylamine

[0020] In a 1000ml three-necked bottle, add 20g 16(17)a-epoxyprednisolone, 30ml DMF, 300ml chloroform, keep warm at 30-35℃, stir and pass in 8g ammonia gas, and react under 1-2 atmospheric pressure After 16 to 20 hours, TLC detects the end point of the reaction. After the reaction, exhaust the ammonia gas in a vacuum, add 3x100ml saturated saline to wash 3 times, then add 100ml pure water to wash once, then concentrate chloroform under reduced pressure to dryness, and add 200ml acetic acid Ethyl ester, 1g activated carbon, stirred and refluxed for 60-90 minutes, cooled to 50-55 degrees, suction filtered while hot, washed carbon with 1-2ml ethyl acetate, combined filtrate and washing liquid, and then concentrated under reduced pressure below 50°C to obtain 95 % ethyl acetate, cool the system to -5-0°C, stir and crystallize for 2 to 3 hours, filter with suction, wash with 0.5-1ml ethyl acetate, combine the lotion and filtrate and set up a...

Embodiment 2

[0024] A: Preparation of hydroxylamine

[0025] In a 1000ml three-necked bottle, add 20g 16(17)a-epoxyprednisolone and 120ml toluene, keep warm at 30-35°C, stir and pass in 8g of ammonia gas, and react at 1-2 atmospheric pressure for 16-20 hours , TLC to detect the end point of the reaction. After the reaction, exhaust the ammonia in a vacuum, add 3x50ml saturated saline to wash, then add 50ml of pure water to wash, then, concentrate toluene under reduced pressure to dryness, add 200ml of ethyl acetate, 1g of activated carbon, and stir to reflux After 60-90 minutes, cool down to 50-55°C, suction filter while it is hot, wash the carbon with 1-2ml ethyl acetate, combine the filtrate and washing liquid, and then concentrate under reduced pressure below 50°C to obtain 95% ethyl acetate. Cool to -5-0°C, stir and crystallize for 2 to 3 hours, filter with suction, wash with 0.5-1ml ethyl acetate, combine the lotion and filtrate and set up a batch; dry the filter cake below 70°C to ob...

Embodiment 3

[0029] A: Preparation of hydroxylamine

[0030]In a 1000ml three-necked bottle, add 20g 16(17)a-epoxyprednisolone and 120ml ethanol, keep warm at 30-35°C, stir and feed 8g of ammonia gas, and react at 1-2 atmospheric pressure for 16-20 hours, TLC detects the end point of the reaction. After the reaction, the ammonia gas is exhausted in vacuum, the ethanol is concentrated under reduced pressure to nearly dryness, the temperature is lowered, 300ml of chloroform is added, the residue is stirred to dissolve, and then 3x100ml of saturated saline is added for washing, followed by 100ml of pure water for washing. , Concentrate chloroform to dryness under reduced pressure, add 200ml ethyl acetate, 1g activated carbon, stir and reflux for 60-90 minutes, cool to 50-55°C, suction filter while hot, wash carbon with 1-2ml ethyl acetate, combine filtrate and lotion , then concentrate under reduced pressure below 50°C to get 95% ethyl acetate, cool the system to -5-0°C, stir and crystallize ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com