Copper-based electric contact material containing graphene/molybdenum disulfide heterojunctions and preparation method of copper-based electric contact material

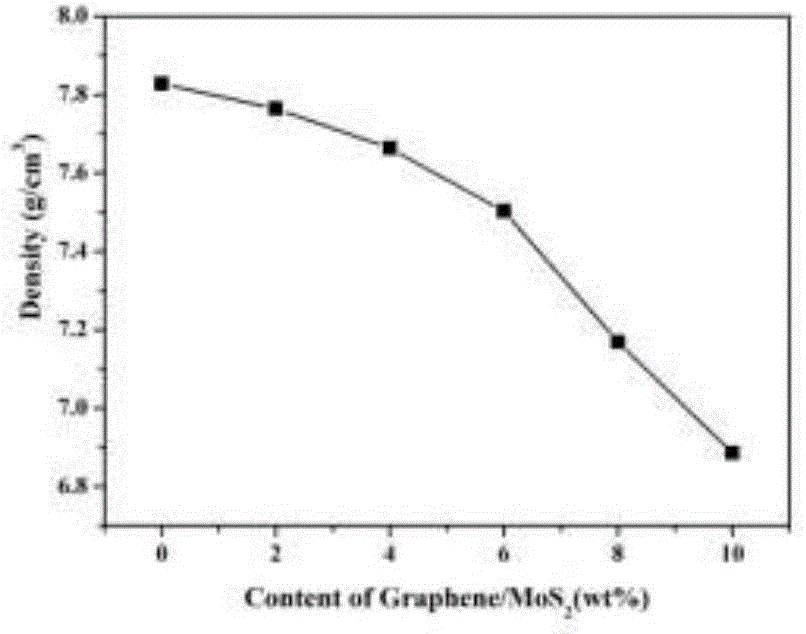

An electrical contact material, molybdenum disulfide technology, applied in the direction of molybdenum sulfide, contacts, circuits, etc., can solve the problems of reducing the thermal conductivity or electrical conductivity of composite electrical contact materials, high temperature mechanical properties, wear resistance is not significantly improved, high density, etc. , to achieve the effect of low density, low price and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Preparation of copper-based self-lubricating electrical contact materials with graphene / molybdenum disulfide heterojunction:

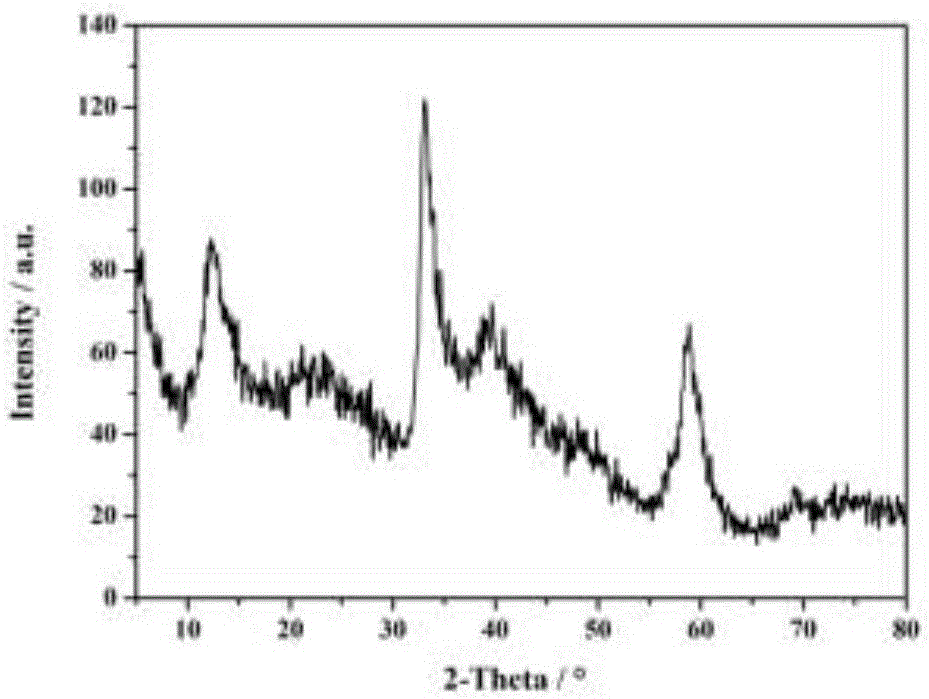

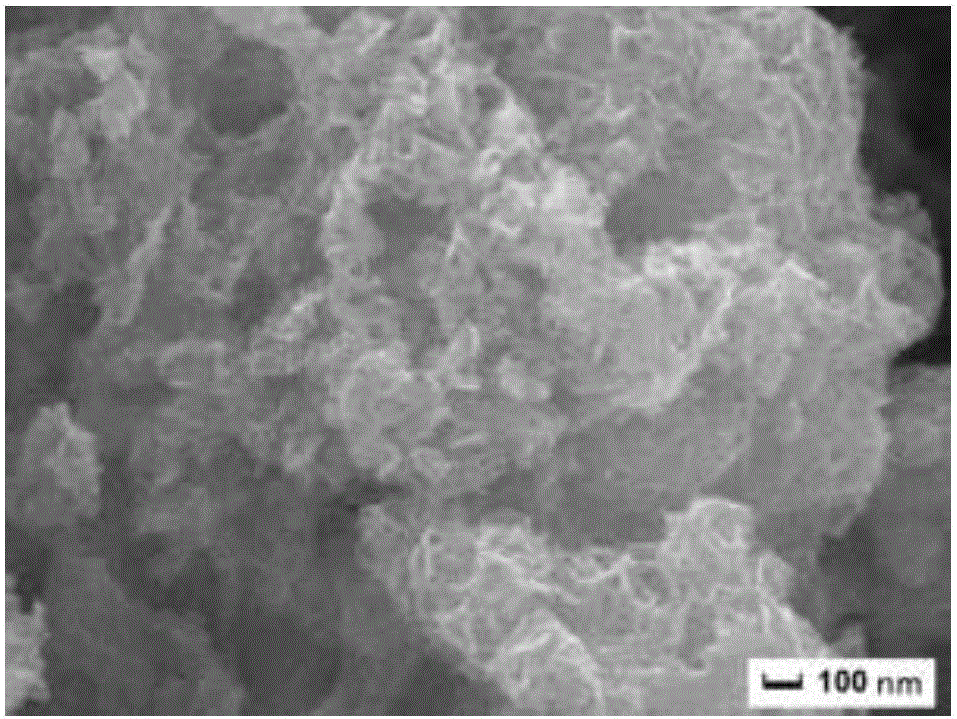

[0040] (1) Preparation of graphene / molybdenum disulfide heterojunction material:

[0041] First, according to the mass ratio of graphene: hexadecyltrimethylammonium bromide (CTAB) = 1:2, weigh 0.05g graphene and 0.1g CTAB respectively, dissolve them in 40mL deionized water, and ultrasonically disperse them for 30min. Graphene solution with good dispersion;

[0042] Then, according to the molar ratio of sodium molybdate: hydroxylamine hydrochloride: thiourea=1:2.2:2, take by weighing 0.3022g sodium molybdate, 0.1910g hydroxylamine hydrochloride, 0.1902g thiourea and add in the graphene solution successively, magnetic stirring 10min ;

[0043] Finally, transfer the mixed solution into a polytetrafluoroethylene-lined hydrothermal kettle, react at 200°C for 24 hours, centrifuge, collect the product, wash with deionized water and absolute ethanol, ...

Embodiment 2

[0049] Preparation of copper-based self-lubricating electrical contact materials with graphene / molybdenum disulfide heterojunction:

[0050] (1) Preparation of graphene / molybdenum disulfide heterojunction material:

[0051] First, according to the mass ratio of graphene: hexadecyltrimethylammonium bromide (CTAB) = 1:2, weigh 0.05g graphene and 0.1g CTAB respectively, dissolve them in 40mL deionized water, and ultrasonically disperse them for 60min. Graphene solution with good dispersion;

[0052] Then, weigh 0.3022g of sodium molybdate, 0.1910g of hydroxylamine hydrochloride, and 0.1902g of thiourea according to the molar ratio of sodium molybdate: hydroxylamine hydrochloride: thiourea=1:2.2:2 and add them to the graphene solution successively, and magnetically stir for 30min ;

[0053] Finally, transfer the mixed solution into a polytetrafluoroethylene-lined hydrothermal kettle, react at 240°C for 24 hours, centrifuge, collect the product, wash with deionized water and abso...

Embodiment 3

[0059] Preparation of copper-based self-lubricating electrical contact materials with graphene / molybdenum disulfide heterojunction:

[0060] (1) Preparation of graphene / molybdenum disulfide heterojunction material:

[0061] First, according to the mass ratio of graphene: hexadecyltrimethylammonium bromide (CTAB) = 1:2, weigh 0.05g graphene and 0.1g CTAB respectively, dissolve them in 40mL deionized water, and ultrasonically disperse them for 45min. Graphene solution with good dispersion;

[0062] Then, according to the molar ratio of sodium molybdate: hydroxylamine hydrochloride: thiourea=1:2.2:2, take by weighing 0.3022g sodium molybdate, 0.1910g hydroxylamine hydrochloride, 0.1902g thiourea and add in the graphene solution successively, magnetic stirring 20min ;

[0063] Finally, transfer the mixed solution into a polytetrafluoroethylene-lined hydrothermal kettle, react at 220°C for 24 hours, centrifuge, collect the product, wash with deionized water and absolute ethanol, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com