Electrode suspension liquid and preparation method thereof

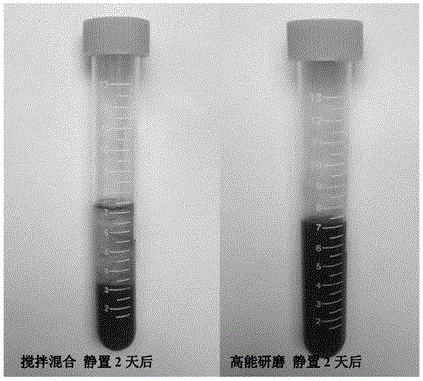

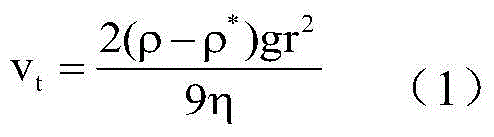

An electrode suspension and electrolyte technology, which is applied in the field of chemical energy storage, can solve the problems of decreased electrochemical performance of lithium ion flow batteries, the diameter can only reach 8 μm, and the particles are easy to agglomerate, so as to avoid rapid sedimentation, reduce loss and Scrap generation and process reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

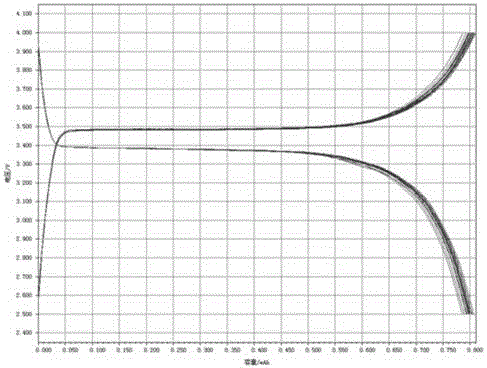

Embodiment 1

[0044] A positive electrode suspension and its preparation method:

[0045] The wet grinding machine used in this embodiment is a planetary ball mill. The specific implementation steps are as follows:

[0046] 1) The positive electrode active material particle is lithium iron phosphate, the conductive agent particle is Ketjen black, weigh 10g of lithium iron phosphate and 1g of Ketjen black, mix evenly, dry in an oven at 80°C for 2 hours, and add it to a ball mill;

[0047] 2) Add 100ml of diethyl carbonate into the ball mill jar;

[0048] 3) Add stainless steel grinding balls in the ball mill jar, the diameter of the grinding balls is 10mm, and the quality of the grinding balls is 100g;

[0049] 4) The ball mill jar is sealed by threads, installed on the ball mill, fixed, and subjected to high-speed grinding, the grinding speed is 500 rpm, and the time is 4 hours;

[0050] 5) After reaching the grinding time, add 50ml of dimethyl carbonate, 50ml of methyl formate, 30g of l...

Embodiment 2

[0053] A kind of negative electrode suspension and preparation method:

[0054] The wet grinding machine used in this embodiment is a sand mill. The specific implementation steps are as follows:

[0055] 1) The negative electrode active material particles are lithium titanate, and the conductive agent particles are carbon fibers. Combine 200g of lithium titanate and 40g of carbon fibers and dry them in an oven at 80°C for 2 hours;

[0056] 2) Add the lithium titanate and carbon fiber dried in step 1) into the sand mill through the powder feeding port of lithium titanate and carbon fiber, and then inject 500ml of vinyl sulfite through the solvent injection port;

[0057] 3) Completely seal the sand mill, set the speed of the sand mill to 200 rpm, and the time is 20 hours. The material is effectively dispersed and pulverized by physical effects such as strong shearing force, friction force, and high-energy ball milling. form a viscous slurry;

[0058] 4) Adjust the valve of t...

Embodiment 3

[0062] A positive electrode suspension and its preparation method:

[0063] The wet grinding machine used in this embodiment is a sand mill. The specific implementation steps are as follows:

[0064] 1) The positive electrode active material particles are lithium cobaltate, the conductive agent particles are carbon black, mix 400g lithium cobaltate and 10g carbon black, and dry in an oven at 80°C for 2 hours;

[0065] 2) Add lithium cobaltate and carbon black dried in step 1) into the sand mill through the powder feeding port of lithium cobaltate and carbon black, and then inject 1000ml propylene carbonate through the solvent injection port;

[0066] 3) Completely seal the sand mill, set the speed of the sand mill to 2000 rpm, and the time is 2 hours. The material is effectively dispersed and pulverized by physical effects such as strong shearing force, friction force, and high-energy ball milling. form a viscous slurry;

[0067] 4) Adjust the valve of the solvent injection...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com