Novel porous metal composite material

A technology of porous metal and composite materials, which is applied in the coating process of metal materials, metal processing equipment, coatings, etc., and can solve problems such as inability to effectively reduce the weight of automobiles, affect the driving safety of automobiles, and uneven material bearing capacity , to achieve the effect of improving driving safety, light weight and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

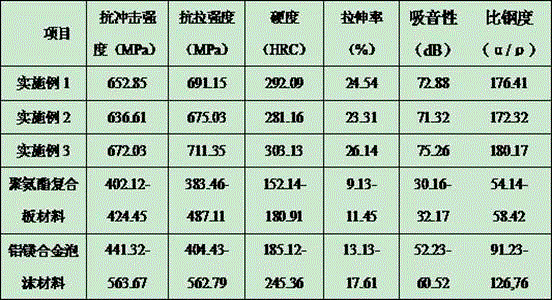

Examples

preparation example Construction

[0057] The preparation method of the novel porous metal composite material comprises the following steps:

[0058] S1: Dissolve polyvinyl alcohol, zinc dioxide sol, and polyvinyl carboxybutyraldehyde in water that is 5-9 times the total mass fraction, then add methyl cellulose, soak for 5-8 hours, and store at 66-74°C Drying at low temperature until the water content is ≤ 8%, and the mixture I is obtained;

[0059] S2: Stainless steel powder, zinc oxide powder, niobium carbide powder, silicon carbide powder, silicon nitride powder, cordierite powder, quartz powder, pore forming agent, epoxy silane, maleic anhydride graft compatibilizer, phosphogypsum, Acrylic bridging agent, acrylate, 701 powder, polyaluminum chloride, fatty acid stabilizer, styrene, 400-700 parts of water at a microwave power of 100-400W, a temperature of 550-600°C, and a speed of 200- Stir at 500r / min for 4-6h, then dry the resultant until the water content is ≤8%, to obtain mixture II;

[0060] S3: Stir t...

Embodiment 1

[0068] A new type of porous metal composite material is made of the following raw materials by weight: 270 parts of substrate, 13 parts of coating;

[0069] The matrix is made of the following raw materials by weight: 140 parts of stainless steel powder, 18 parts of zinc oxide powder, 16 parts of niobium carbide powder, 14 parts of silicon carbide powder, 12 parts of silicon nitride powder, and 10 parts of cordierite powder , 9 parts of quartz powder, 8 parts of polyvinyl alcohol, 6 parts of zinc dioxide sol, 4 parts of methyl cellulose, 5 parts of polyvinylcarboxybutyraldehyde, 13 parts of pore-forming agent, 1.2 parts of epoxy silane, maleic anhydride 1 part of graft compatibilizer, 1 part of phosphogypsum, 0.8 part of acrylic bridging agent, 1.2 parts of acrylate, 0.5 part of 701 powder, 0.5 part of polyaluminum chloride, 0.3 part of fatty acid stabilizer, 0.2 part of styrene ;

[0070] The pore-forming agent is made of the following raw materials in units of weight: 14 ...

Embodiment 2

[0097] A new type of porous metal composite material is made of the following raw materials by weight: 195 parts of substrate, 12 parts of coating;

[0098] The matrix is made of the following raw materials by weight: 128 parts of stainless steel powder, 15 parts of zinc oxide powder, 14 parts of niobium carbide powder, 12 parts of silicon carbide powder, 10 parts of silicon nitride powder, and 8 parts of cordierite powder , 8 parts of quartz powder, 6 parts of polyvinyl alcohol, 4 parts of zinc dioxide sol, 3 parts of methyl cellulose, 4 parts of polyvinylcarboxybutyraldehyde, 10 parts of pore-forming agent, 0.8 parts of epoxy silane, maleic anhydride 0.6 parts of graft compatibilizer, 0.8 parts of phosphogypsum, 0.6 parts of acrylic bridging agent, 0.5 parts of acrylate, 0.4 parts of 701 powder, 0.4 parts of polyaluminum chloride, 0.2 parts of fatty acid stabilizer, 0.2 parts of styrene ;

[0099] The pore-forming agent is made of the following raw materials in units of wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com