A kind of molybdenum disulfide/graphene hollow composite microsphere and preparation method thereof

A technology of molybdenum disulfide and composite microspheres, which is applied in the manufacture of hybrid/electric double layer capacitors and electrodes of hybrid capacitors, can solve problems such as poor conductivity, unsatisfactory stability, and limited specific capacitance, and achieve favorable Effects of diffusion and transport, excellent electrochemical performance, and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

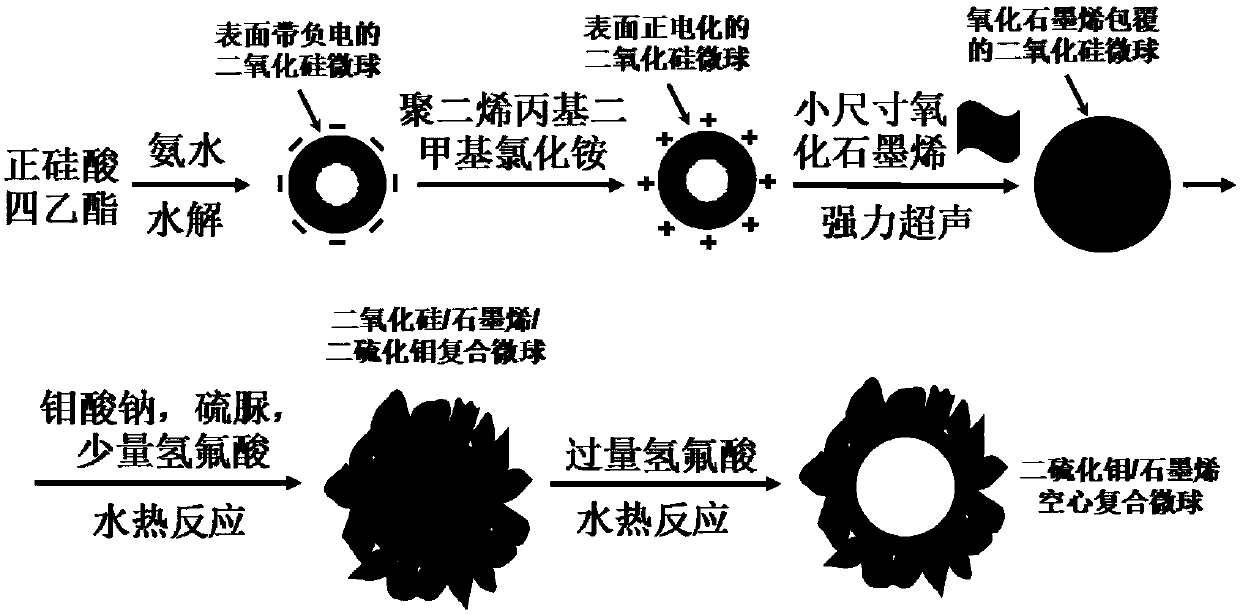

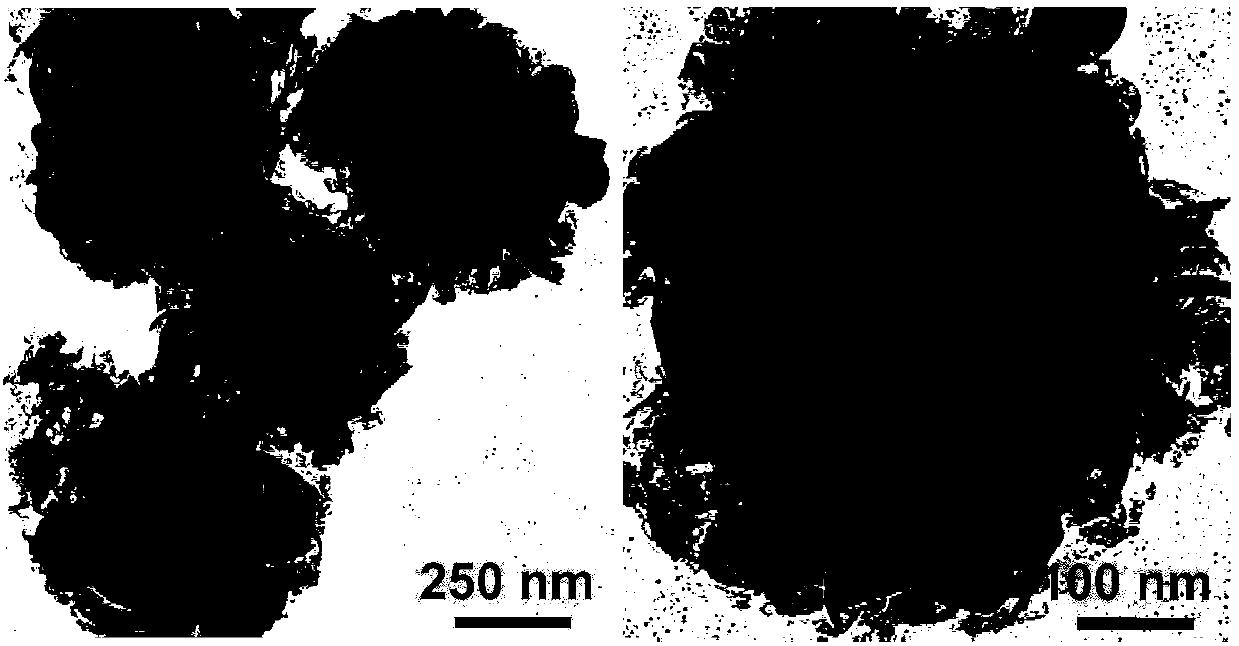

[0034] Embodiment 1: the method provided by the invention is used to prepare molybdenum disulfide / graphene hollow composite microspheres ( figure 1 ):

[0035] (1) Silica colloidal microspheres with an average particle size of 200 nm were prepared by a slightly improved Stöber method [(a) Wang, W.; Gu, B.; Liang, L.; Hamilton, W. A. J. Phys. Chem. B 2003, 107 , 3400-3404. (b) Wang, W.; Gu, B.; Liang, L.; Hamilton, W. A. J. Phys. Chem. B 2003, 107 , 12113-12117.].

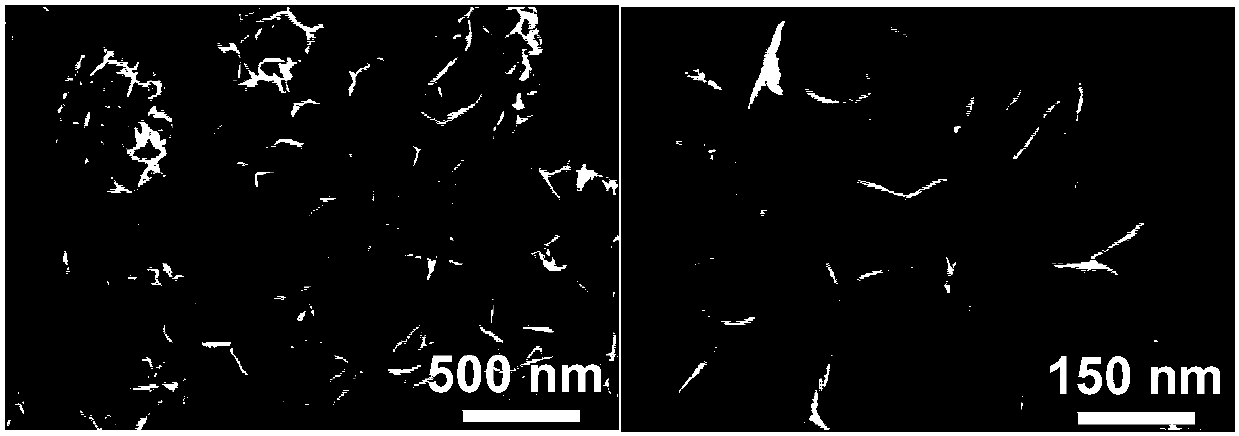

[0036] (2) A layer of graphene oxide was modified on the surface of the silica microspheres prepared in step (1) by means of ultrasonic-assisted interfacial self-assembly to obtain silica / graphene oxide composite microspheres with an average size of 200 nm ( Xiao, W.; Zhang, Y.; Liu, B. ACS Appl. Mater. Interfaces 2015, 7 , 6041-6046.).

[0037] (3) Ultrasonic disperse 80 mg of the silica / graphene oxide composite microspheres in step (2) in 55 mL of water, and then add dropwise 5 mL of 155 mg of sodium mo...

Embodiment 2

[0041] Embodiment 2: The molybdenum disulfide / graphene hollow composite microsphere synthesized in embodiment 1 is used as a supercapacitor electrode material to test its electrochemical performance:

[0042] (1) Weigh 40 mg molybdenum disulfide / graphene hollow composite microspheres synthesized in Example 1, 5 mg acetylene black and 5 mg polyvinylidene fluoride respectively and mix them into an agate mortar, then add 350 μL of N-methylpyrrolidone and fully ground into a slurry, and then the slurry was evenly coated on the surface of the nickel foam, the coating area was 1 cm × 1 cm, and then the nickel foam coated with the active material was put into Vacuum oven, 60 o C and fully dried for more than 6 h to obtain the working electrode.

[0043] (2) The nickel foam coated with the active material in step (1) is used as the working electrode, the Hg / HgO electrode is used as the reference electrode, the Pt sheet electrode is used as the auxiliary electrode and the potassium hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com