Crystalline copolymer polyimide resin low in melt viscosity and prone to melt processing and application

A polyimide resin, melt viscosity technology, used in adhesives, coatings, etc., can solve the problems of high melting point and melt viscosity, processing temperature over 400 ℃, poor melt crystallization ability, etc., to reduce processing temperature. and melt viscosity, excellent melt crystallinity, easy melt processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Add 14.6165g (50.0mmol) TPER, 2.8966g (7.2mmol) 3,3',4,4'-triphenylene ether tetracarboxylic dianhydride to a three-necked flask equipped with a stirrer, reflux condenser and nitrogen gas guide tube (referred to as HQDPA), 12.0042g (40.8mmol) BPDA, 0.5925g (4.0mmol) PA, 180g m-cresol, 10 drops of isoquinoline, react under nitrogen atmosphere, stir evenly, heat up to 200°C for 8 hours , cooled to room temperature, adding ethanol as a precipitant, the polymer was precipitated in powder form, washed with a large amount of ethanol and water, and then dried in a vacuum oven at 150° C. for 10 hours to obtain polyimide resin PI-1.

[0056] The inherent viscosity of PI-1 measured by an Ubbelohde viscometer in a m-cresol solution with a concentration of 0.5 g / dL at 30° C. is 0.51 dL / g.

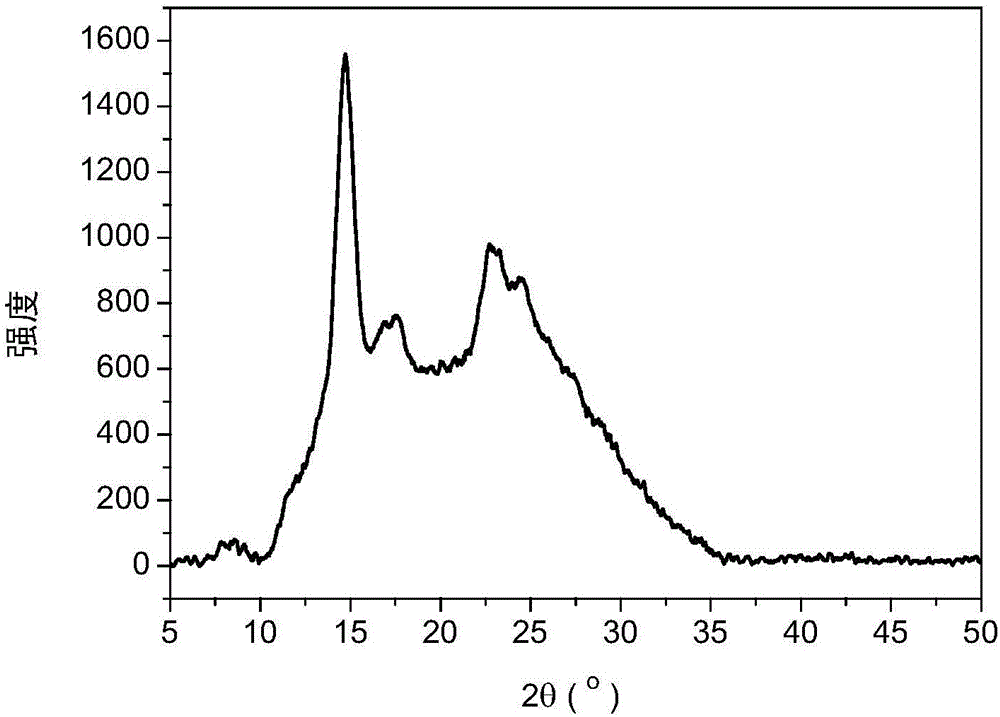

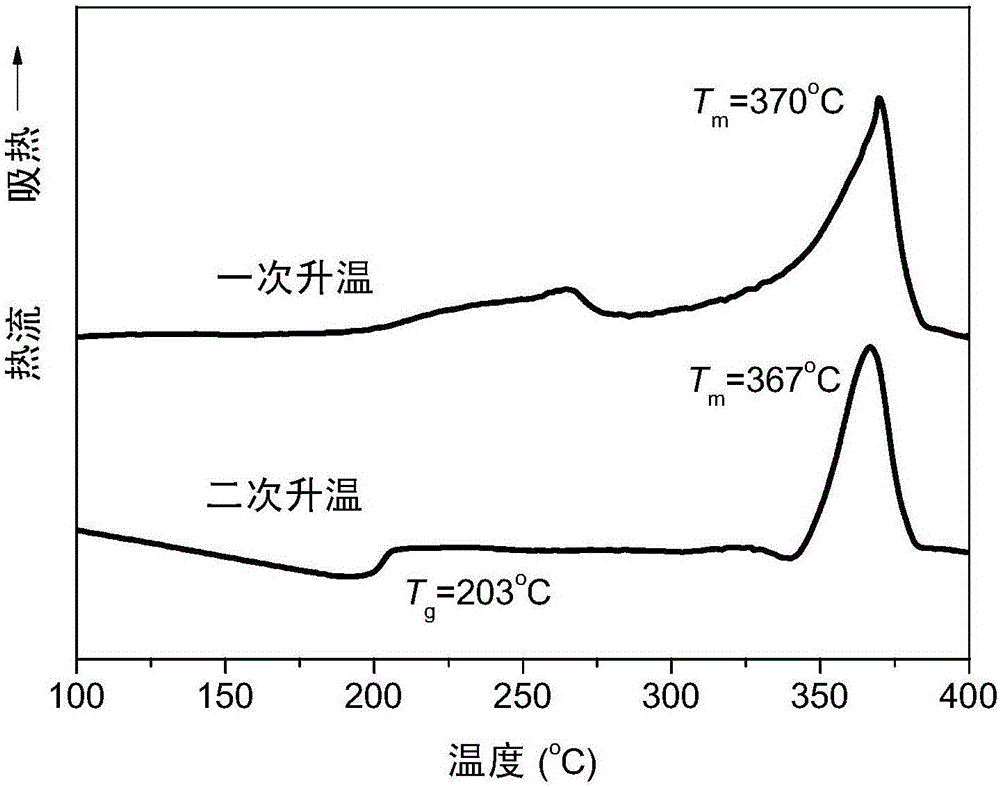

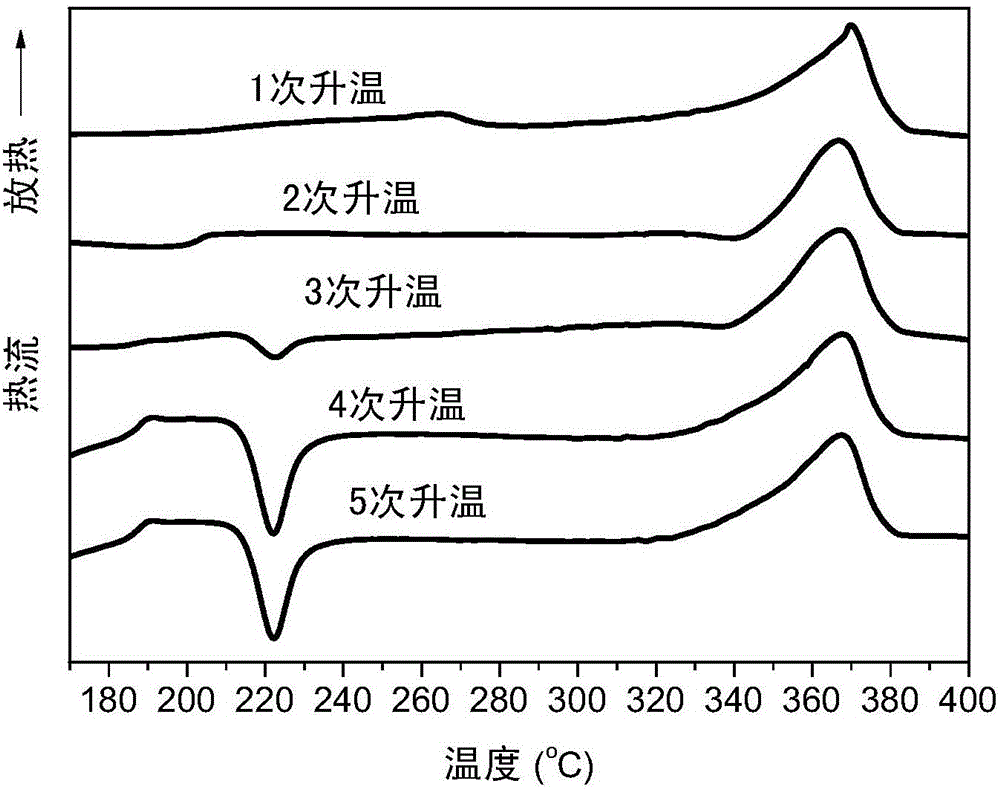

[0057] The X-ray powder diffraction pattern of the polymer is shown in figure 1 As shown, it has the sharp characteristic diffraction peaks of crystalline polymers (with high crystallinity).

...

Embodiment 2

[0061] Add 14.6165g (50.0mmol) TPER, 1.9311g (4.8mmol) HQDPA, 12.7103g (43.2mmol) BPDA, 0.5925g (4.0mmol) PA, 180g m-cresol, 10 drops of isoquinoline, react under nitrogen atmosphere, stir evenly, heat up to 200 ° C for 8 hours, cool to room temperature, add ethanol as a precipitant, the polymer is precipitated in powder form, use a large amount of ethanol and washed with water, and then dried in a vacuum oven at 150° C. for 10 hours to obtain polyimide resin PI-2.

[0062] The obtained PI-2 was measured by DSC, as a result, only the melting point T was observed in the first heating curve m is 376°C, no clear observation of Tg and T c (with a high degree of crystallinity). T is observed in the second warming g 193°C, T m It is 378°C. Its 5% thermal decomposition temperature in air is measured to be 543°C. The inherent viscosity is 0.60dL / g. The melt complex viscosity measured by rotational rheometer is 1240 Pa·s (at 423° C.).

Embodiment 3

[0064] Add 14.6165g (50.0mmol) TPER, 3.8622g (9.6mmol) HQDPA, 11.2980g (38.4mmol) BPDA, 0.5925g (4.0mmol) PA, 180g m-cresol, 10 drops of isoquinoline, react under nitrogen atmosphere, stir evenly, heat up to 200 ° C for 8 hours, cool to room temperature, add ethanol as a precipitant, the polymer is precipitated in powder form, use a large amount of ethanol and washed with water, and then dried in a vacuum oven at 150° C. for 10 hours to obtain polyimide resin PI-3.

[0065] The obtained PI-3 was measured by DSC, as a result, only the melting point T was observed in the first heating curve m is 358°C, no clear observation of T g and T c (with a high degree of crystallinity). T is observed in the second warming g 191°C, T m It is 356°C. Its 5% thermal decomposition temperature in air is measured to be 546° C., and the inherent viscosity is 0.55 dL / g. The melt complex viscosity measured by rotational rheometer is 750 Pa·s (at 417° C.).

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com