Structure for improving water/oxygen barrier performance of flexible substrate and preparation method of structure

A water-oxygen barrier and flexible substrate technology, applied in semiconductor/solid-state device manufacturing, photovoltaic power generation, electrical components, etc., can solve problems that affect device life, deterioration, and poor flexibility of ultra-thin glass, so as to improve overall performance and Reliability, reduce temperature gradient and junction temperature, improve the effect of water and oxygen barrier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

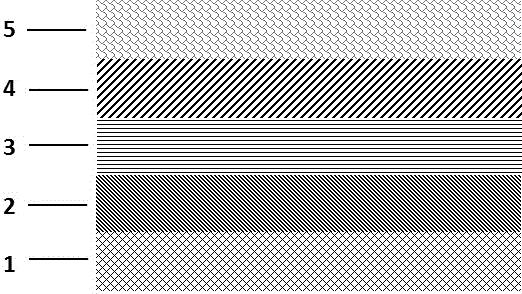

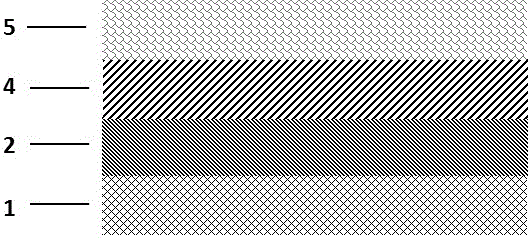

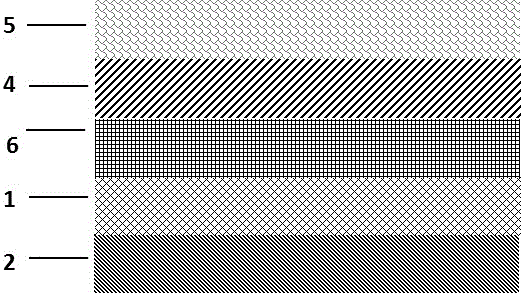

Image

Examples

Embodiment 1

[0020] Example 1 Graphene water-oxygen barrier layer and Ag compound to prepare OLED device with high light extraction efficiency

[0021] 1) Graphene CVD preparation: A copper foil (1cm*1cm) with a thickness of 25 microns and a purity of 99.8wt% was ultrasonically cleaned in acetone, isopropanol, and deionized water for 20 minutes. The cleaned copper foil is used as a polished anode, and the copper plate is used as a cathode for electrochemical polishing. Among them, the proportion of the electrolyte is deionized water: phosphoric acid: ethanol: isopropanol: urea = 100ml: 50ml: 50ml: 10ml: 1g. The polished copper foil was then ultrasonically cleaned with acetone, ethanol, and deionized water for 10 minutes, and dried with high-purity nitrogen. Put the copper foil in the CVD reaction chamber, evacuate until the pressure in the reaction chamber drops below 1Pa, and then pass in a hydrogen / argon gas mixture (hydrogen 10%) to normal pressure. After repeating this step 3 times, c...

Embodiment 2

[0026] Example 2 Graphene water and oxygen barrier layer doubles as electrode to prepare transparent OLED device

[0027] 1) Graphene CVD preparation: Place copper foil (6cm*10m) with a thickness of 25 microns and a purity of 99.8wt% in the roll-to-roll PECVD reaction chamber in turn, and vacuum until the pressure in the reaction chamber drops below 1Pa, and then pass through Hydrogen / argon mixed gas (hydrogen 20%) to normal pressure, repeat this step 3 times, control the mixed gas flow rate to 100sccm, heat up to 900°C, adjust the power of the RF power supply to 300W to generate the plasma glow of the whole tube, and inject carbon Source precursor CH 4 , the flow rate is 200sccm, the pressure is 650Pa, the moving speed of the copper foil is set to 60cm / hour, the carbon source precursor is cut off after the growth is completed, the flow rate of the mixed gas is kept constant, and the temperature is lowered to room temperature.

[0028] 2) Graphene transfer: In step 1), the ro...

Embodiment 3

[0031] Embodiment 3 single graphene as flexible substrate water oxygen barrier layer

[0032] 1) Graphene CVD preparation: Nickel foil (3cm*3cm) with a thickness of 20 microns and a purity of 99.9wt% was ultrasonically cleaned in acetone, isopropanol, and deionized water for 10 minutes, and dried with nitrogen. Place it in the CVD reaction chamber, evacuate until the pressure in the reaction chamber drops below 1Pa, and then introduce hydrogen / argon mixed gas (hydrogen 10%) to normal pressure. After repeating this step 3 times, control the flow rate of the mixed gas to 100 sccm, Raise the temperature to 1000°C and feed the carbon source precursor C 2 h 2 , the flow rate is 20 sccm, the temperature is kept at 650 Pa for 10 minutes, the carbon source precursor is cut off, the flow rate of the mixed gas is kept constant, and the temperature is rapidly cooled to room temperature.

[0033] 2) Graphene transfer: In step 1), the obtained nickel / graphene is transferred to a PI subst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com