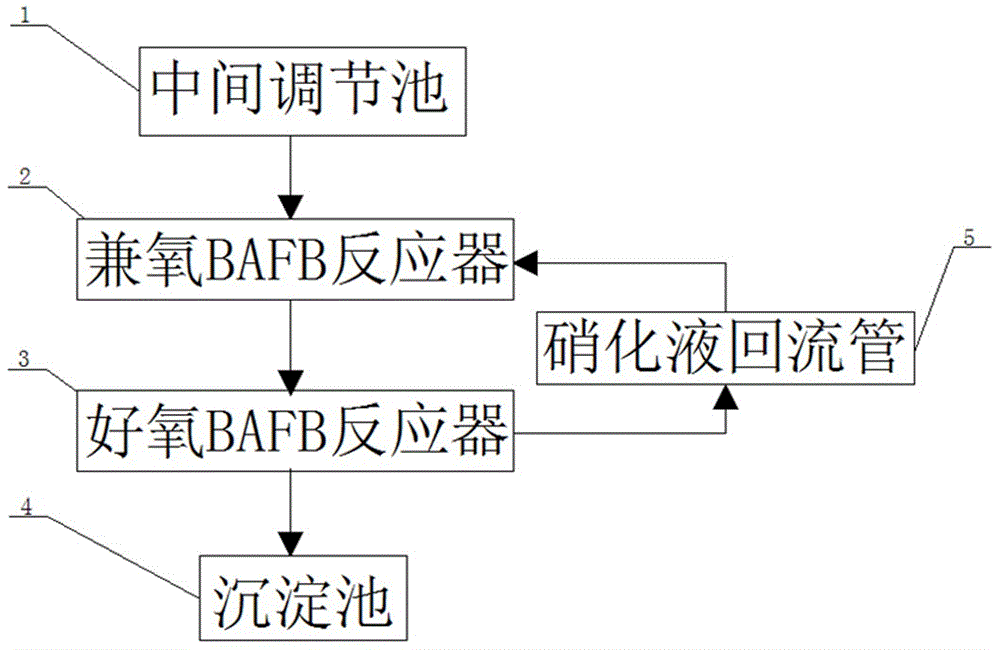

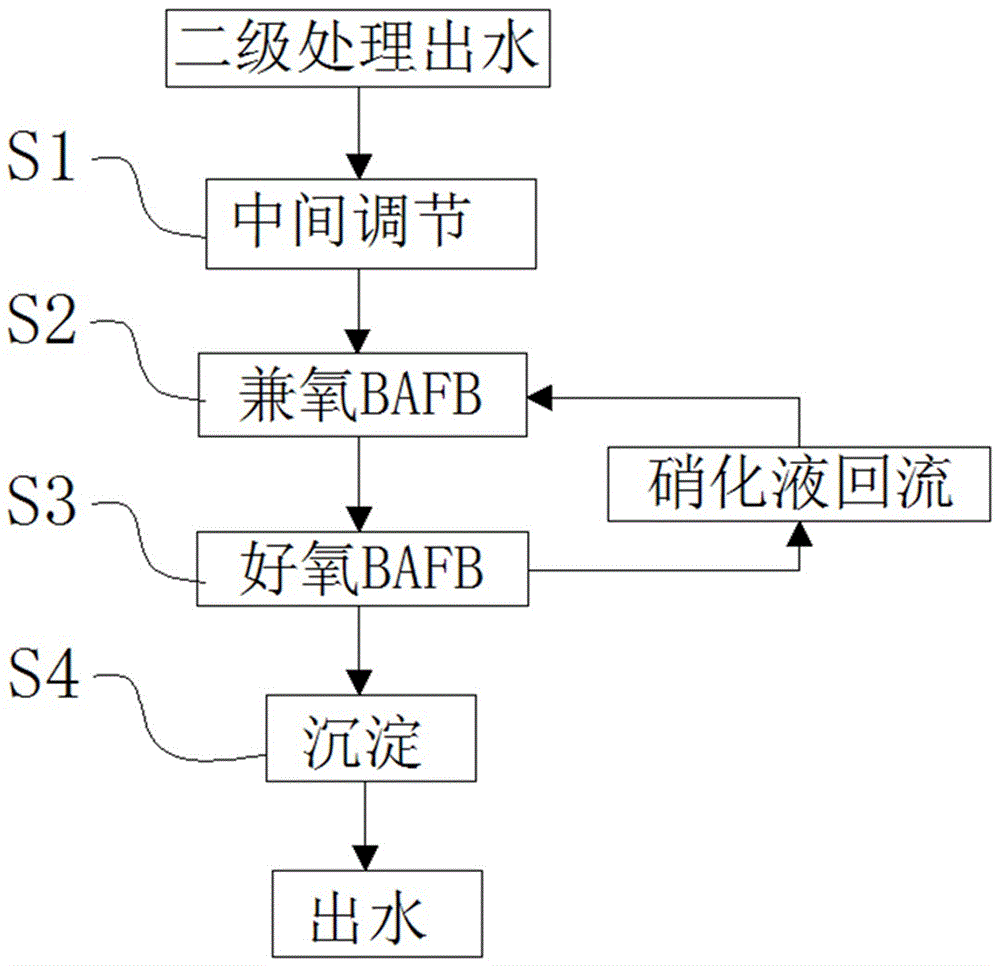

Device and process for advanced treatment of immobilized functional microbe wastewater

A technology for advanced treatment of functional microorganisms, applied in the field of advanced treatment devices for immobilized functional microbial wastewater, which can solve problems such as unstable process operation, difficult upgrading and transformation, and large capital investment, and achieves small footprint, good removal effect, and infrastructure construction The effect of less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] 1. Preparation of embedding agent: add 50-100g of polyvinyl alcohol and 5-20g of sodium alginate into 0.2L of water and mix, then place in hot water at 95°C to dissolve in a water bath to prepare embedding agent;

[0041]2. Preparation of the mixed solution: Add 5-20g of magnet powder with a particle size of 0.03-0.05mm and 5-20g of powdered activated carbon with a particle size of less than 0.075mm into the embedding agent, and mix well to obtain a mixed solution;

[0042] 3. Addition of bacteria slime: Suspend 60g of bacteria slime with 20ml0.9wt% sodium chloride deionized water, then add it to the mixed solution cooled to room temperature, and filter after mixing evenly; Anaerobic and facultative microorganisms such as nitrifying denitrification bacteria and high-efficiency decolorizing bacteria, or high-efficiency functional microorganisms targeting characteristic pollutants such as high-efficiency ammonia-oxidizing bacteria, high-efficiency nitrifying bacteria, high...

example 1

[0059] The comprehensive wastewater of a textile dyeing and finishing enterprise in Zhejiang, the raw water COD is about 1400mg / L, the chroma is about 1000 times, the SS is about 300mg / L, and the pH is about 8.5. After the secondary treatment, the COD of the biochemical treatment effluent is about 230mg / L, the pH is about 7.5, the chroma is about 250 times, and the SS is about 90mg / L. The effluent quality does not meet the water quality standards.

[0060] The secondary biochemical effluent of this enterprise is used as the influent of the wastewater advanced treatment process of the present invention, and the DOcr Immobilized microspheres of degrading bacteria, the filling rate (volume) is 30%-50%.

[0061] After being treated by the wastewater advanced treatment process of the present invention, the effluent chroma is ≤25 times, CODcr≤50mg / L, SS≤20mg / L, pH is 7.5, and meets the "Water Pollutant Discharge Standard for Textile Dyeing and Finishing Industry" (GB4287-2012) The s...

example 2

[0063] A sewage treatment plant mainly produces industrial sewage, accounting for more than 80%. The industrial sewage is mainly synthetic leather DMF wastewater and textile wastewater, including some pharmaceutical wastewater and electroplating wastewater. The main influent water quality indicators are: COD Cr ≤450mg / L, BOD 5 ≤160mg / L, SS≤300mg / L, NH 4 + -N≤25mg / L, pH6-9, chroma≤80 times, total phosphorus≤5mg / L, total nitrogen≤35mg / L. The existing treatment process is fine grid + cyclone grit chamber + adjustment, sedimentation tank + hydrolysis acidification tank + improved reaction tank + mechanical reaction tank (flocculation tank) + fiber filter (D-type filter) + ClO 2 Disinfect pool. COD of the effluent after the existing process of the sewage treatment plant Cr Average 65mg / L, NH 4 + -N average 10mg / L, total nitrogen average 20mg / L, COD cr , NH 4 + -N, total nitrogen cannot meet the relevant effluent discharge standards.

[0064] The effluent of the sewage tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com