Method for continuous extraction of tannin and pectin from persimmon peel

A technology for persimmon peel and pectin, which is applied in chemical instruments and methods, preparation of sugar derivatives, esterified saccharides, etc., can solve problems such as waste of resources, improve viscosity, reduce production costs, and enhance viscosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

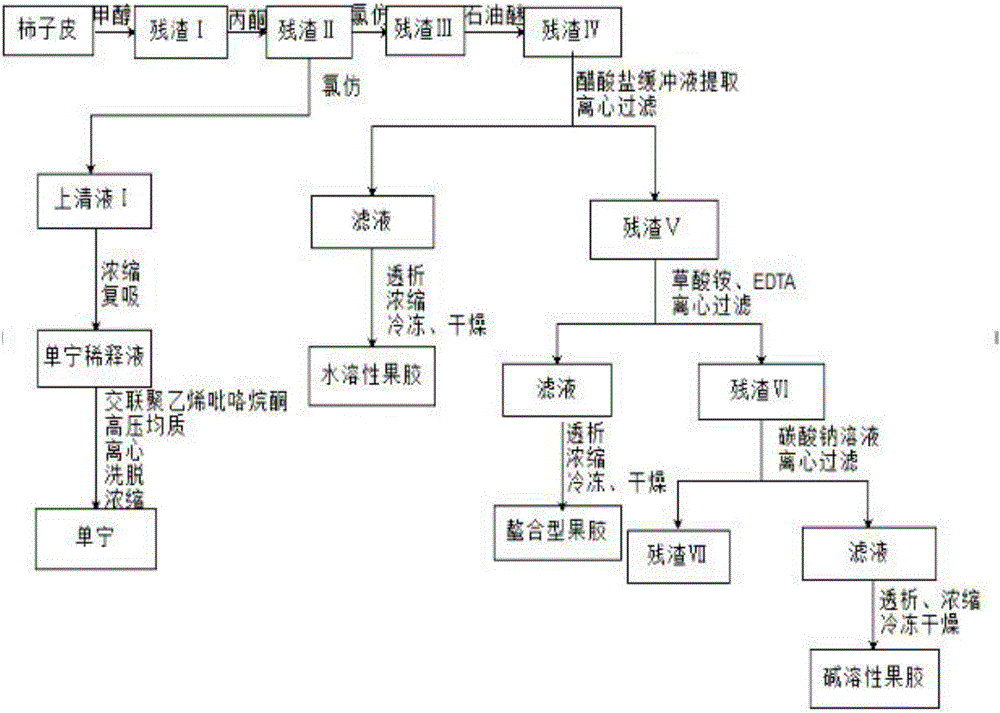

Method used

Image

Examples

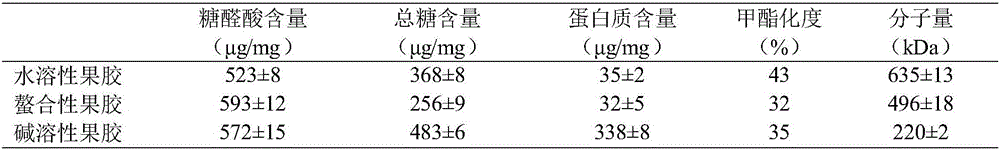

Embodiment 1

[0039] 1. Take 100 grams of persimmon skin, then dry it, pulverize it, and sieve it to obtain 95 grams of raw material powder.

[0040] 2. Add 90 grams of the raw material powder to 1 liter of methanol, centrifuge and filter to obtain the residue I; add 70 grams of the residue I to 0.8 liter of acetone, centrifuge and filter to obtain the residue II; add 60 grams to 0.7 liter of chloroform The residue II is centrifuged and filtered to obtain residue III and supernatant I.

[0041] 3. Concentrate the supernatant I, then dilute the concentrated supernatant solution with distilled water, the volume concentration of the dilution is 9%, add cross-linked polyvinylpyrrolidone to the tannin diluent, and the prepared mass concentration is

[0042] 13%, high pressure homogenization at 55°C for 25min, pressure is 125Mpa, then centrifuged at 15000rpm for 13 minutes, take the precipitate, wash the precipitate twice with an equal volume of ethanol solution with a mass concentration of 70-85...

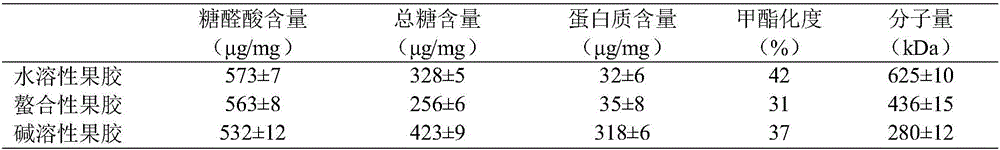

Embodiment 2

[0050] 1. Take 100 grams of persimmon skin, then dry it, pulverize it, and sieve it to obtain 94 grams of raw material powder.

[0051] 2. Add 100 grams of raw material powder to 1 liter of methanol solution with a mass concentration of 98%, and filter to obtain residue I; add 80 grams of residue I to 0.8 liter of acetone solution with a mass concentration of 97%, and filter to obtain residue II; 70 g of residue II was added to 1 liter of chloroform, and 68 g of residue III and supernatant liquid I were obtained by filtration.

[0052] 3. Concentrate the supernatant I, and then dilute the concentrated supernatant solution with distilled water, the volume concentration of dilution is 10%, add cross-linked polyvinylpyrrolidone to the tannin diluent, the prepared mass concentration is 15%, 60 ℃ Homogenize under high pressure for 30min, the pressure is 150Mpa, then centrifuge at 15000rpm for 15 minutes, take the precipitate, wash the precipitate three times with an equal volume of...

Embodiment 3

[0060] 1. Take 100 grams of persimmon skin, then dry it, pulverize it, and sieve it to obtain 96 grams of raw material powder;

[0061] 2. Add 80 grams of raw material powder to 1 liter of methanol, and filter to obtain residue I; add 64 grams of residue I to 0.8 liter of acetone, and filter to obtain residue II; add 56 grams of residue II to 0.7 liter of chloroform, and filter to obtain 56 g of residue III and supernatant I.

[0062] 3. Concentrate the supernatant I, and then dilute the concentrated supernatant solution with distilled water, the volume concentration of dilution is 8%, add cross-linked polyvinylpyrrolidone to the tannin diluent, the prepared mass concentration is 10%, 60 ℃ Homogenize under high pressure for 20min, the pressure is 100Mpa, then centrifuge at 15000rpm for 10 minutes, take the precipitate, wash the precipitate twice with an equal volume of 70-85% ethanol solution, and then vacuum rotary evaporation at 40°C The ethanol solution with a mass concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com