Preparation method of spherical nano hydroxyapatite particles

A nano-hydroxyapatite and particle technology, applied in the field of biomedical materials, can solve the problems of high hollow ratio, large particle size and low crystallinity, and achieve the effects of low cost, uniform particles and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it is not limited thereto. Any modification or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the technical solution of the present invention should be covered by the present invention. within the scope of protection.

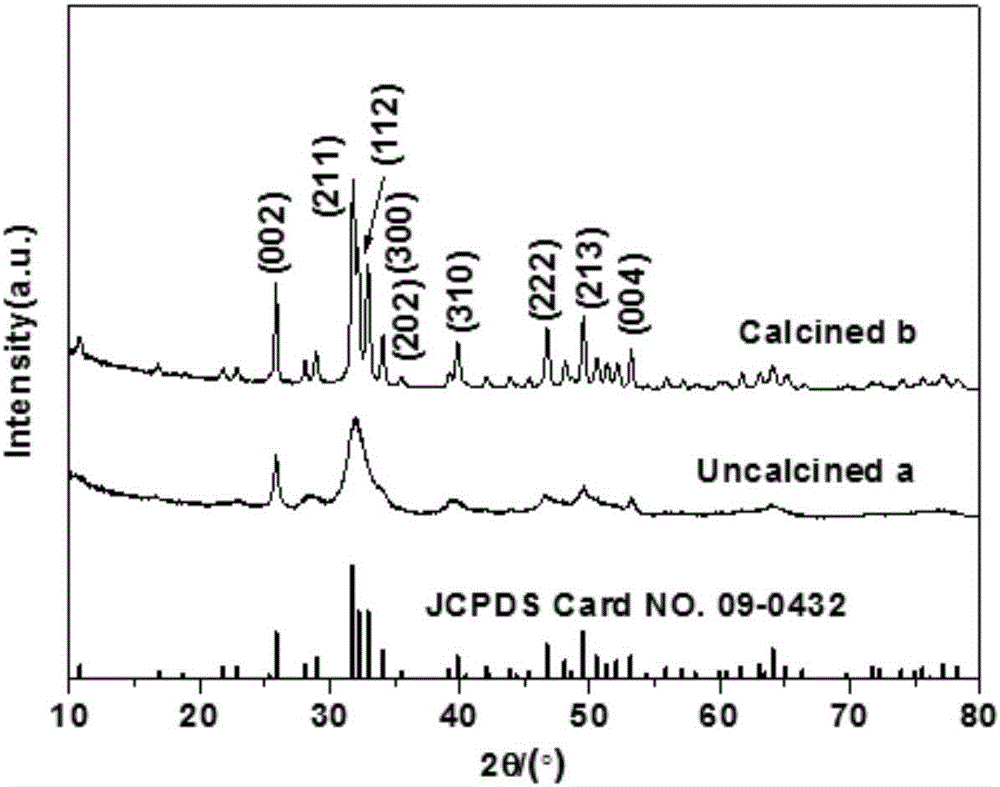

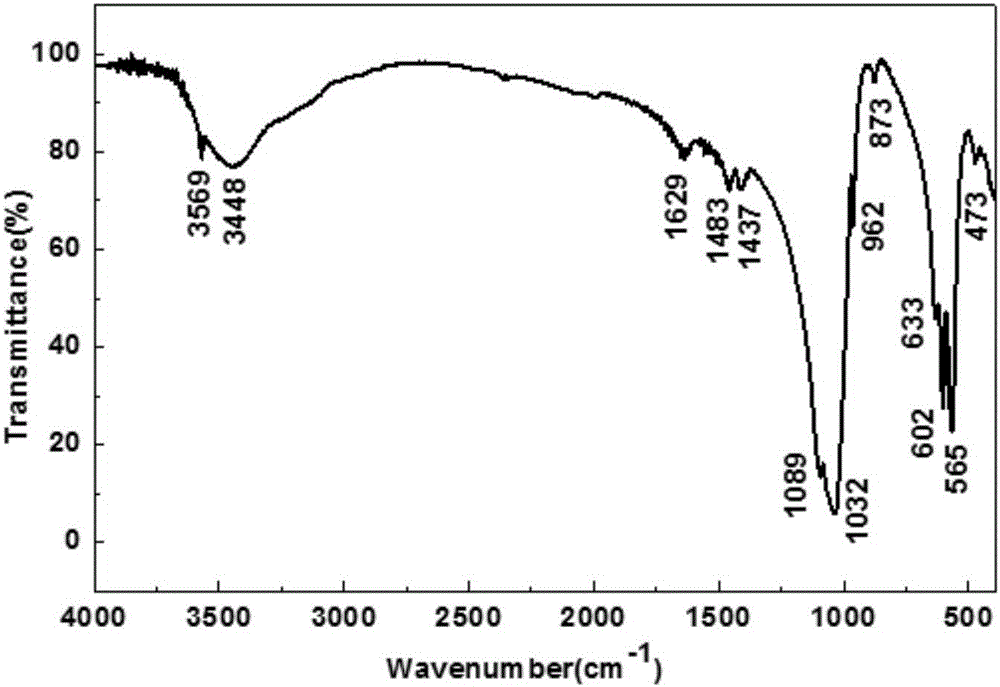

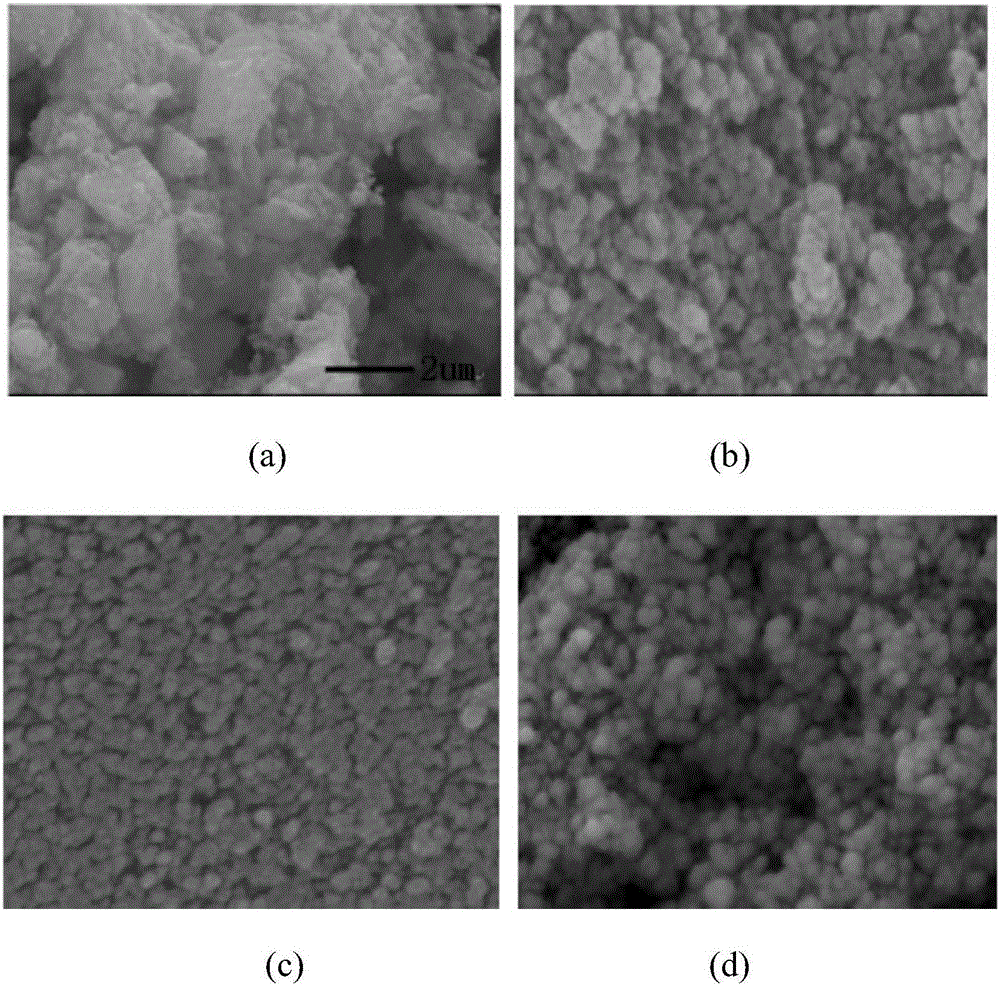

[0020] The invention provides a method for preparing spherical nano-hydroxyapatite particles. First, a dilute solution of sucrose is used to prepare carbon quantum dots under hydrothermal treatment, which is used as an effective nucleation inducer, wherein sulfuric acid is used as a carbonizing agent; Dilute it with deionized water, add dropwise sodium hydroxide aqueous solution to adjust the pH value of the solution, using anhydrous calcium chloride and disodium hydrogen phosphate as raw materials, Ca 2+ Adsorbed on the surface of carbon quantum dots b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com