A kind of amino acid sugar ester, its preparation method and application

An amino acid sugar ester and amino acid technology, applied in the petroleum industry, can solve the problems of biodegradability and environmental friendliness to be improved, and achieve the effects of non-toxicity, good chemical stability and good biodegradability in the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] Correspondingly, the present invention provides a kind of preparation method of amino acid sugar ester, comprises the following steps:

[0042] In the presence of a catalyst, react an amino acid with a monosaccharide in a solvent to obtain an amino acid sugar ester;

[0043] The amino acid is selected from glycine, glutamic acid, alanine or aspartic acid, and the monosaccharide is selected from glucose, galactose, fructose, mannose or ribose;

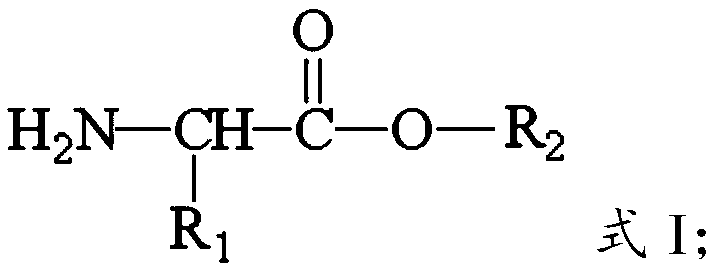

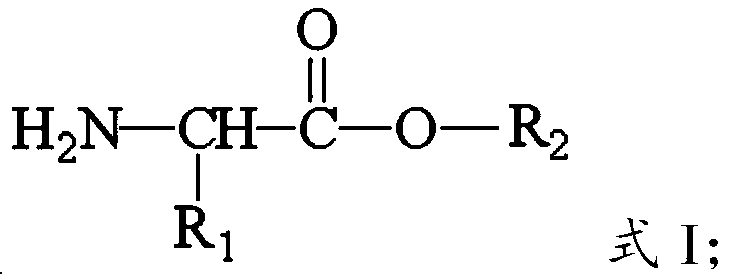

[0044] The amino acid sugar ester has the structure of formula I:

[0045]

[0046] In formula I, R 1 selected from hydrogen, methyl, -CH 2 COOH or -CH 2 CH 2 COOH;

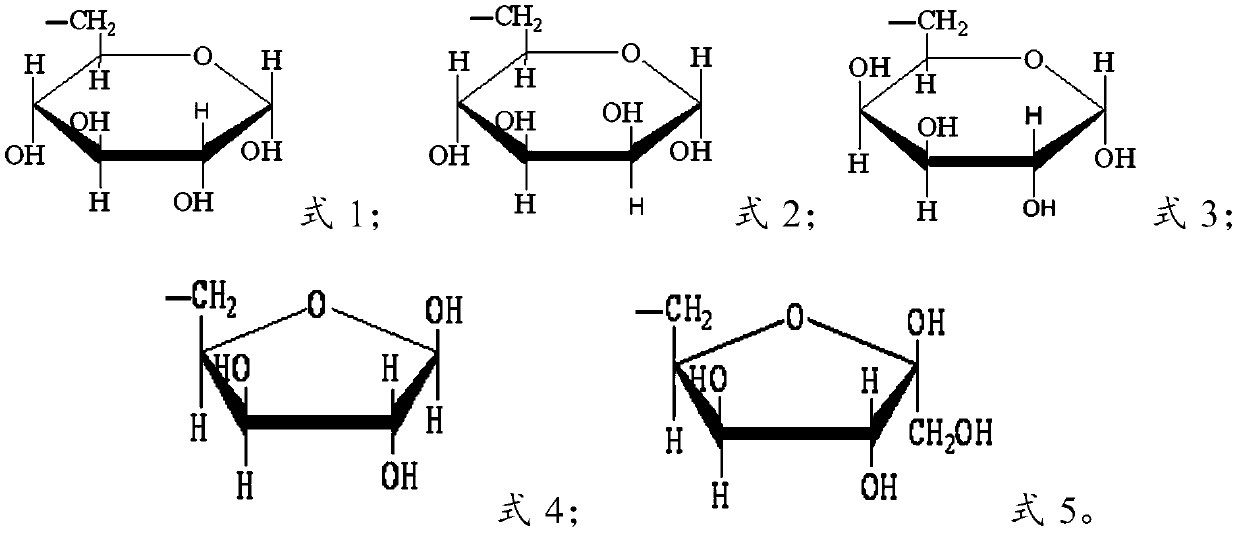

[0047] R 2 Any one selected from the groups shown in formulas 1 to 5:

[0048]

[0049] The second object of the present invention is to provide a method for preparing amino acid sugar ester, and the prepared amino acid sugar ester can be used as the base oil of drilling fluid. In addition, the preparation method of the amino acid sugar ester provided ...

Embodiment 1

[0066] (1) Add 75 parts by weight of glycine, 150 parts by weight of glucose, 10 parts by weight of papain, and 100 parts by weight of 1-butyl-3-methylimidazolium hexafluorophosphate ionic liquid solvent into a reaction kettle with stirring, condensation and heating devices , stir and mix evenly, react at 30°C and 150rpm for 20h, and cool down to room temperature to obtain a crude solution of glycine-glucose ester.

[0067] (2) Add 150 parts by weight of n-hexane extractant in the crude solution of above-mentioned glycine glucose ester three times altogether, each addition is 50 parts by weight, after mixing uniformly, leave standstill, the gained solution is divided into two layers; A separatory funnel with a capacity of 1000mL was used to separate, and the lower layer was 1-butyl-3-methylimidazolium hexafluorophosphate-papain mixture, and the upper layer was glycine glucose ester-n-hexane solution; wherein, 1-butyl-3- Methylimidazolium hexafluorophosphate-papain mixture can ...

Embodiment 2

[0071] (1) 165 parts by weight of glutamic acid, 180 parts by weight of galactose, 35 parts by weight of α-chymotrypsin, 200 parts by weight of 1-butyl-3-methylimidazolium tetrafluoroborate ionic liquid solvent are added with stirring, condensation and In the reaction kettle of the heating device, stir and mix evenly, react at 50° C. and 200 rpm for 24 hours, and cool down to room temperature to obtain a crude solution of galactosyl glutamate.

[0072] (2) Add 300 parts by weight of cyclohexane extractant in the crude solution of the above-mentioned galactosyl glutamate for three times, each addition is 100 parts by weight, after mixing evenly, let it stand, and the gained solution is divided into Two layers; separated by a separatory funnel with a capacity of 1000mL, the lower layer is 1-butyl-3-methylimidazolium tetrafluoroboric acid-α-chymotrypsin mixture, and the upper layer is galactosyl glutamate-cyclohexane solution ; Wherein, the 1-butyl-3-methylimidazolium tetrafluoro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com