Preparation device and preparation method of nicarbazin

A technology for nicarbazine and preparation device, which is applied to the preparation device and preparation field of nicarbazine, can solve the problems of uneconomical method, difficult to complete reaction, less consideration of raw materials, etc., and achieves simplified solvent treatment, reduced reaction cost, simplified processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

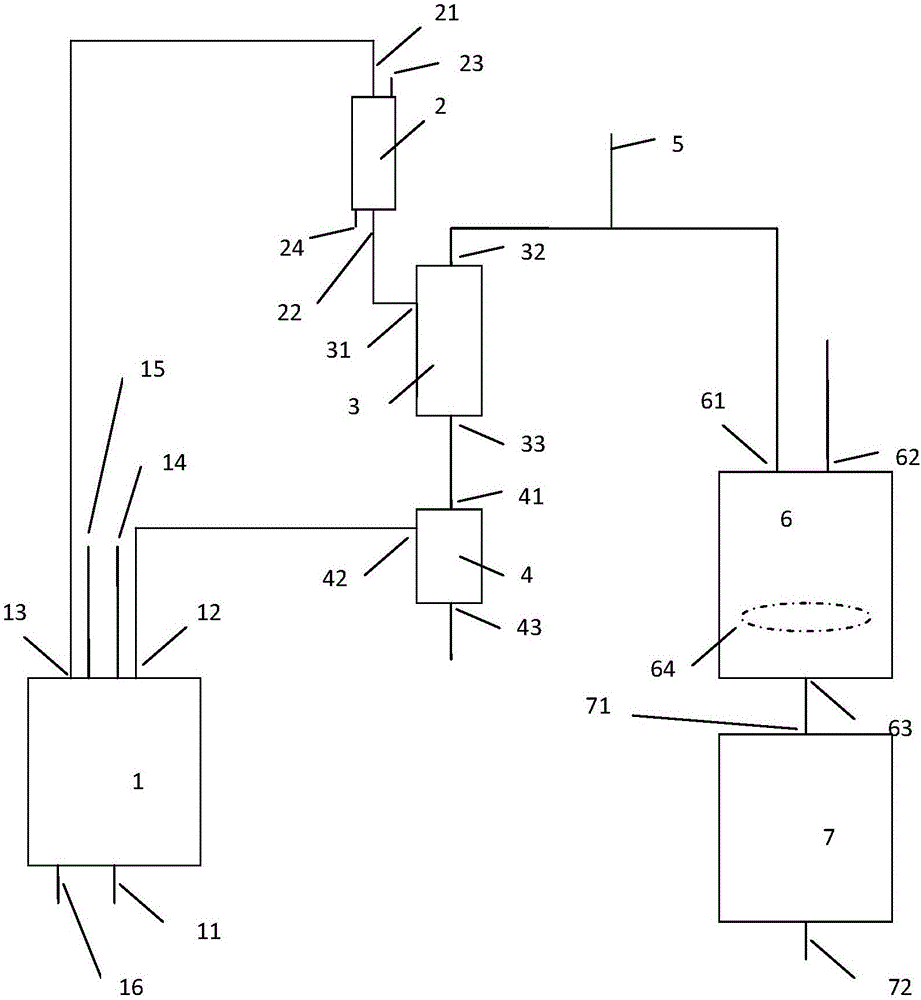

Image

Examples

Embodiment 1

[0059] Add 120g of p-nitroaniline with a water content of 8% to a 2000mL four-necked bottle equipped with a thermometer, mechanical stirring, water separator and a condenser tube connected to the water separator, add 1000g of butyl acetate, and heat to reflux under stirring Separation of water, initially the solvent returned by the condenser tube was turbid due to water. When the liquid returned by the condenser tube becomes clear, it means that there is no moisture in the system. Stop heating, add 41.5g of triphosgene after cooling down to room temperature, remove the water separator at the same time, change to direct condensation and reflux, and connect the air guide tube at the top of the condensation tube, and introduce the generated hydrogen chloride gas into 250g of anhydrous methanol. The reaction system was heated to reflux for 15 hours, and the amount of p-nitroaniline in the system was monitored by TLC. When the raw materials were completely consumed, the reaction co...

Embodiment 2

[0062] Add 120g of p-nitroaniline with a water content of 8% and 1100g of toluene to a 2000mL four-necked bottle equipped with a thermometer, mechanical stirring, and a water separator, and a condenser tube connected to the water separator, and heat under reflux to separate water under stirring. , Initially, the solvent returned from the condenser tube was turbid due to water content. When the liquid returned by the condenser tube becomes clear, it means that there is no moisture in the system. Stop heating, add 40.3g of triphosgene after cooling down to room temperature, remove the water separator at the same time, change to direct condensation and reflux, and connect the air guide tube on the top of the condensation tube, and introduce the generated hydrogen chloride gas into 250g of anhydrous methanol. The reaction system was heated to reflux for 18 hours, and the amount of p-nitroaniline in the system was monitored by TLC. When the raw materials were completely consumed, t...

Embodiment 3

[0065] Add 350g of p-nitroaniline with a water content of 6% to a 5000mL four-necked bottle equipped with a thermometer, a mechanical stirrer, a water separator, and a condenser tube connected to the water separator, add 3000g of xylene, and heat to reflux under stirring. Water, initially the solvent returned from the condenser tube was turbid due to water content. When the liquid returned by the condenser tube becomes clear, it means that there is no moisture in the system. Stop heating, add 121.5g of triphosgene after cooling down to room temperature, and remove the water separator at the same time, change to direct condensation and reflux, and connect a gas guide tube to the top of the condensation tube, and introduce the generated hydrogen chloride gas into 900g of absolute ethanol. The reaction system was heated to reflux for 15 hours, and the amount of p-nitroaniline in the system was monitored by TLC. When the raw materials were completely consumed, the reaction could b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com