Preparation method of ultra-overbased synthetic magnesium sulfonate

A technology of ultra-high base number and magnesium sulfonate, applied in lubricating compositions, petroleum industry, additives, etc., can solve the problems of high magnesium content, high precipitation value and high base number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

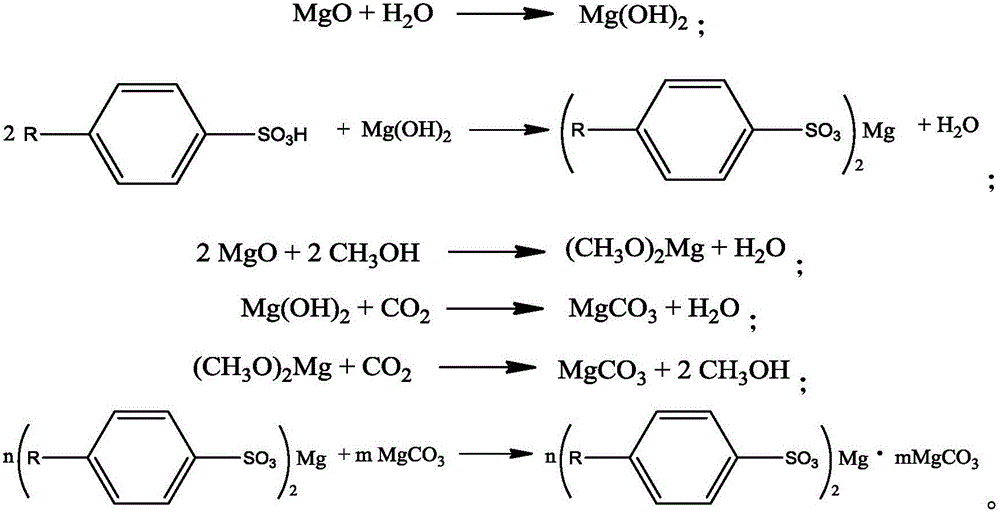

[0022] The embodiment of the present invention discloses a preparation method for synthesizing magnesium sulfonate with ultra-high base value, comprising the following steps:

[0023] A), mixing one of polyisobutylene succinic anhydride and polyisobutylene succinamide, organic solvent, small molecule organic acid, saturated fatty acid, low carbon alcohol, heavy alkylbenzene sulfonic acid and linear alkylbenzene sulfonic acid, get the mixture;

[0024] B), add the mixture of magnesia and diluent oil in the mixture, add water and co-accelerator after heating up the reaction, and pass into carbon dioxide, then add the mixture of magnesia and dilute oil, pass into carbon dioxide, will get after reaction The reaction material is heated to remove low-carbon alcohol and water to obtain a liquid material;

[0025] Or, B), adding a mixture of magnesium oxide and diluent oil to the mixture, adding water and a co-accelerator after heating up the reaction, and introducing carbon dioxide,...

Embodiment 1

[0034] The preparation of embodiment 1 linear alkylbenzenesulfonic acid

[0035] Add 10g of red oil and 150g of toluene into the reaction kettle, and drop 100g of C20~C24α-olefins into the reaction kettle at 50~60°C (the mass ratio of C20, C22 and C24 is 40~55:20~35:5~ 25), after the dropwise addition, continue to react for a period of time, stand still for 2 to 4 hours to separate layers, take the supernatant and filter, and then remove unreacted toluene through distillation to obtain 120 g of C20-C24 long-chain linear alkylbenzene; C24 long-chain linear alkylbenzene was slowly passed into 30g of sulfur trioxide gas for sulfonation reaction at 40-60°C for 30 minutes, and then aged to divide the acid to obtain 140g of C20-C24 long-chain linear alkylbenzenesulfonic acid (average molecular weight 470- 530, active material content 83~93wt%).

[0036] Preparation of Heavy Alkylbenzenesulfonic Acids

[0037] Add 200g of heavy alkylbenzene with a distillation range of 385°C to 450...

Embodiment 2

[0040] Add 100g of xylene, 3g of formic acid, 6g of stearic acid, 20g of methanol, and 3g of alkene anhydride into a 500ml flask and mix well, then add 35g of a mixture of heavy alkylbenzenesulfonic acid and linear alkylbenzenesulfonic acid with a mass ratio of 10:90 , add 30g of a mixture of magnesium oxide and base oil with a mass ratio of 1:2, raise the temperature to 40-50°C for neutralization for 30min, add 5g of water, inject 3L of carbon dioxide at a gas rate of 120ml / min, add 15g of 20% ammonia water, and then add Take 30g of magnesium oxide and base oil mixture with a mass ratio of 1:2, keep the temperature constant, then ventilate to 13L, stop ventilating, heat the reaction material to 100°C under the pressure of -0.035mpa, remove the alcohol water in the system, and get 145g of liquid material, the turbidity of the measured material is 120NTU; add 155g of xylene and heat to 50°C and centrifuge under the condition of a centrifugal force of 500g to obtain 297g of super...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Base value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com