Polymer modified material for encapsulating microorganisms and its preparation method and application in n,n-dimethylformamide treatment

A technology for modifying materials and polymers, used in biological water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., can solve problems such as low degradation efficiency and bacterial poisoning, achieve considerable adsorption performance, and avoid the loss of bacteria , the effect of low economic cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

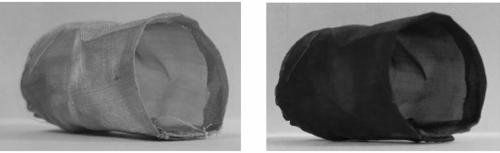

[0031] Copper mesh pretreatment and model preparation. Specific steps are as follows:

[0032] First make the copper mesh into a bag model, then put it in water, ultrasonic for half a day, then put it in DMF for half a day, dry it in an oven and stick it into a bag model with a hot melt glue gun.

[0033] Preparation of graphene oxide. Specific steps are as follows:

[0034] Make a mixed solution of concentrated sulfuric acid and concentrated phosphoric acid at a ratio of 9:1, then slowly add 1.5 graphite flakes, keep the temperature below 50°C, and react for 5 hours, then slowly pour the solution into ice water, Stir while adding, and finally add 30% hydrogen peroxide slowly until the solution turns bright yellow. Then wash by centrifugation with 5% hydrochloric acid and water.

[0035] Modification of graphene oxide. Specific steps are as follows:

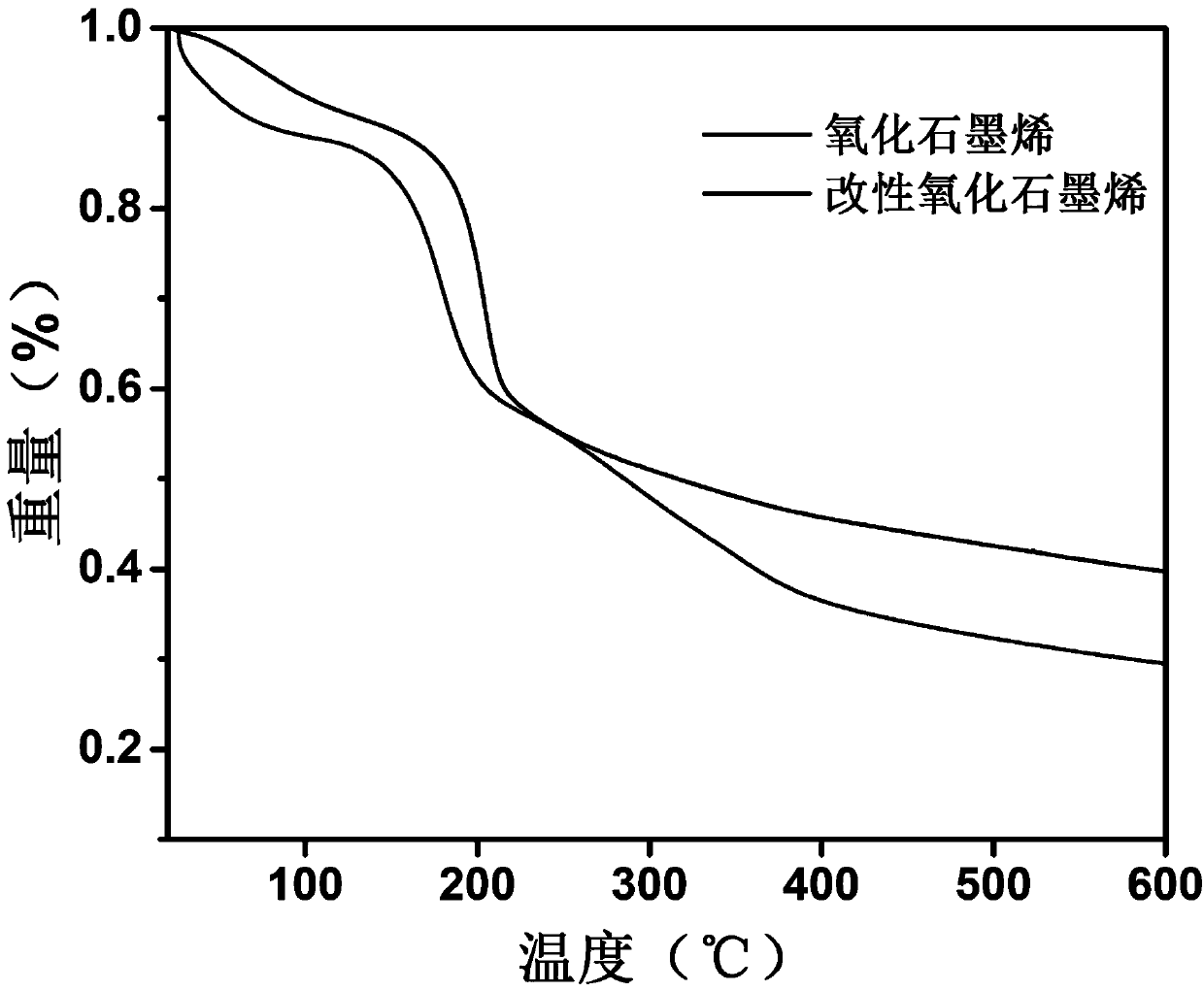

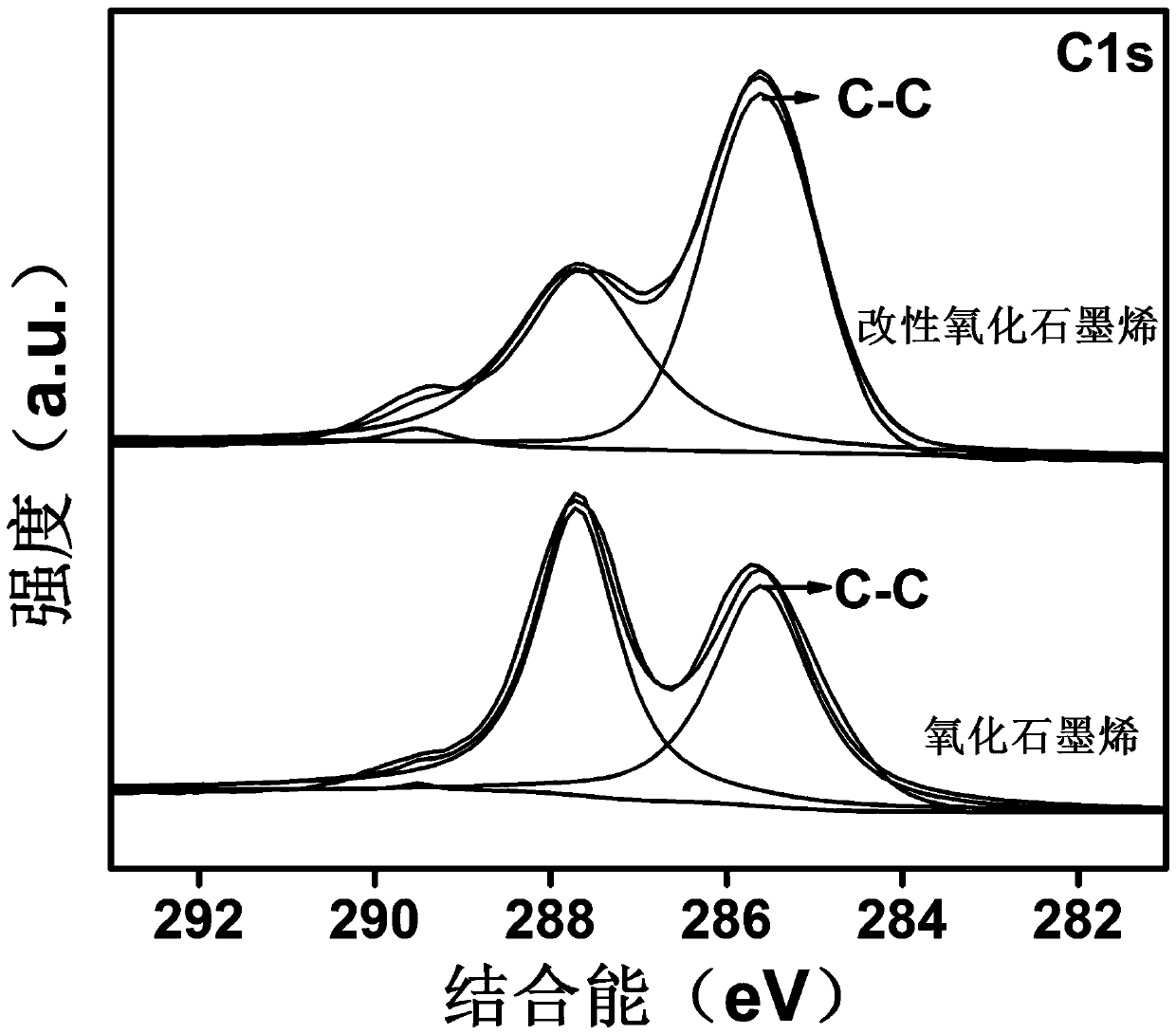

[0036] In a round bottom flask, GO was dispersed in DMAC and triethylamine was added. The reaction system was carried ou...

Embodiment 2

[0050] First make the copper mesh into a bag model, then put it in water, ultrasonic for half a day, then put it in DMF for half a day, dry it in an oven and stick it into a bag model with a hot melt glue gun.

[0051] Make a mixed solution of concentrated sulfuric acid and concentrated phosphoric acid at a ratio of 10:1, then slowly add 2g of graphite flakes, keep the temperature below 40°C, and react for 6 hours, then slowly pour the solution into ice water, Stir while adding, and finally add 35% hydrogen peroxide slowly until the solution turns bright yellow. Then centrifuge and wash with 10% hydrochloric acid and water to obtain graphene oxide.

[0052] In a round bottom flask, GO was dispersed in DMAC and triethylamine was added. The reaction system was carried out under the protection of vacuum and nitrogen, and then acryloyl chloride was slowly added thereto (ice-water bath), followed by overnight at room temperature for 30 hours, the product was washed with acetone, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com