Production line and production process of electroless nickel immersion gold

A technology of chemical nickel gold and production process, which is applied in the field of chemical nickel gold production line and production process, can solve the problems of rising production cost and labor cost, prolonging the processing process, scraping of circuit board, etc., and achieve saving of manpower, manufacturing cost and production The effect of cost reduction and sewage discharge reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

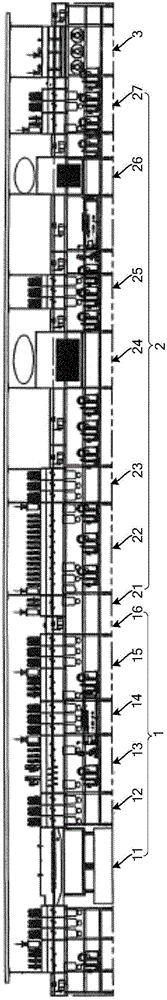

Image

Examples

Embodiment 1

[0047] Chemical nickel plating solution formula: nickel sulfate 20g / L, reducing agent: sodium hypophosphite 25g / L, complexing agent: a mixture of sodium succinate, lactic acid, and ammonium chloride, accelerator: acetic acid 5g / L, stabilizer: Lead acetate is 1ppm, and the pH value is controlled at about 8. Heat it to 70°C and immerse the circuit board in it for 15 minutes.

[0048] Chemical gold plating solution formula: gold potassium cyanide 3g / L, complexing agent: ethylenediaminetetraacetic acid (EDTA) 20g / L, auxiliary complexing agent: hydroxyethylidene diphosphonic acid (HEDP) 20g / L. It was heated to 80°C and the circuit board was immersed in it for 6 minutes.

[0049] After actual operation, using the above electroless nickel plating solution and electroless gold plating solution for plating, the obtained coating appearance, adhesion, corrosion resistance and surface flatness of the coating can all meet the requirements.

Embodiment 2

[0051] Chemical nickel plating solution formula: nickel sulfate 20g / L, reducing agent: sodium hypophosphite 30g / L, complexing agent: a mixture of sodium succinate, lactic acid, and ammonium chloride, accelerator: acetic acid 10g / L, stabilizer: Lead acetate is 1ppm, and the pH value is controlled at about 7.5. Heat it to 80°C and immerse the circuit board in it for 10min.

[0052] Chemical gold plating solution formula: gold potassium cyanide 2g / L, complexing agent: ethylenediaminetetraacetic acid (EDTA) 20g / L, auxiliary complexing agent: hydroxyethylidene diphosphonic acid (HEDP) 15g / L. It was heated to 73°C and the circuit board was immersed in it for 6 minutes.

[0053] After actual operation, using the above electroless nickel plating solution and electroless gold plating solution for plating, the obtained coating appearance, adhesion, corrosion resistance and surface flatness of the coating can all meet the requirements.

Embodiment 3

[0055] Chemical nickel plating solution formula: nickel sulfate 24.5g / L, reducing agent: potassium hypophosphite 25g / L, complexing agent: a mixture of sodium succinate, lactic acid, ammonium chloride, accelerator: propionic acid 5g / L, stable Agent: lead acetate 1ppm, and the pH value is controlled at about 5.5. It was heated to 62°C and the circuit board was immersed in it for 15 minutes.

[0056] Chemical gold plating solution formula: gold potassium cyanide 2g / L, complexing agent: hydroxyethylimine diacetic acid 30g / L, auxiliary complexing agent: aminotrimethylene phosphonic acid (ATMP) 25g / L. It was heated to 80°C and the circuit board was immersed in it for 6 minutes.

[0057] After actual operation, using the above electroless nickel plating solution and electroless gold plating solution for plating, the obtained coating appearance, adhesion, corrosion resistance and surface flatness of the coating can all meet the requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com