Mineralized collagen bionic bone repair material modified by hyaluronan oligosaccharide and preparation method of mineralized collagen bionic bone repair material

A hyaluronic acid oligosaccharide and collagen biomimetic bone technology, which is applied in the fields of analysis materials, tissue regeneration, instruments, etc., can solve the problems of multiple operations and unrealized bone microstructure biomimetic, achieve low cost and improve biocompatibility , the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Preparation of glycosylated collagen (Col / HA, HA is hyaluronic acid raw material before enzymatic hydrolysis):

[0065] Preparation of the reaction system: Weigh 80 mg of collagen, 20 mg of HA (5K), recrystallized NaBH 3 CN 30mg in a 25mL glass bottle, add the prepared reaction system (i.e. HFP and 0.1M NaHCO 3 Mixed medium, volume ratio 3:2) 5mL, under dark conditions, 37°C, magnetic stirring for 24h;

[0066] Cleaning of reaction samples: After the reaction, transfer the reaction solution to a small beaker, add 5% acetic acid for 8-fold dilution, and put it into six 30K ultrafiltration tubes, 4000g / min, 25min / time, ultrafiltration and centrifugal replacement 6 times, and then collect samples for vacuum freeze-drying;

[0067] Determination of the sugar loading of the reaction sample: the sugar content of the dried Col / HA was measured by the carbazole-ethanol method, and the sugar loading was determined to be 5.266%.

Embodiment 2

[0069] Preparation of glycosylated collagen (Col / oHAs, oHAs are oligosaccharides after enzymatic hydrolysis):

[0070] The preparation method as described in Example 1, the difference is that collagen 80mg, oHAs (776.5-2293.4) 20mg, recrystallized NaBH 3 CN 30mg, ultrafiltration and centrifugal replacement 4 times.

[0071] The sugar content of the dried Col / HA was measured by the carbazole-ethanol method, and the sugar loading was determined to be 2.101%.

[0072] oHAs is the glycosylation modification of collagen with hyaluronic acid oligosaccharides. Hyaluronic acid oligosaccharides are tetrasaccharides, hexasaccharides, octasaccharides, decasaccharides, and dodecasaccharides obtained after enzymatic hydrolysis, separation and purification of 5k sodium hyaluronate And its mixture, the molecular weight range is 776-2293Da.

[0073] For the preparation steps of hyaluronic acid oligosaccharides, see "Optimum Conditions for Hyaluronic Acid Hydrolysis Catalyzed by Hyaluronid...

Embodiment 3

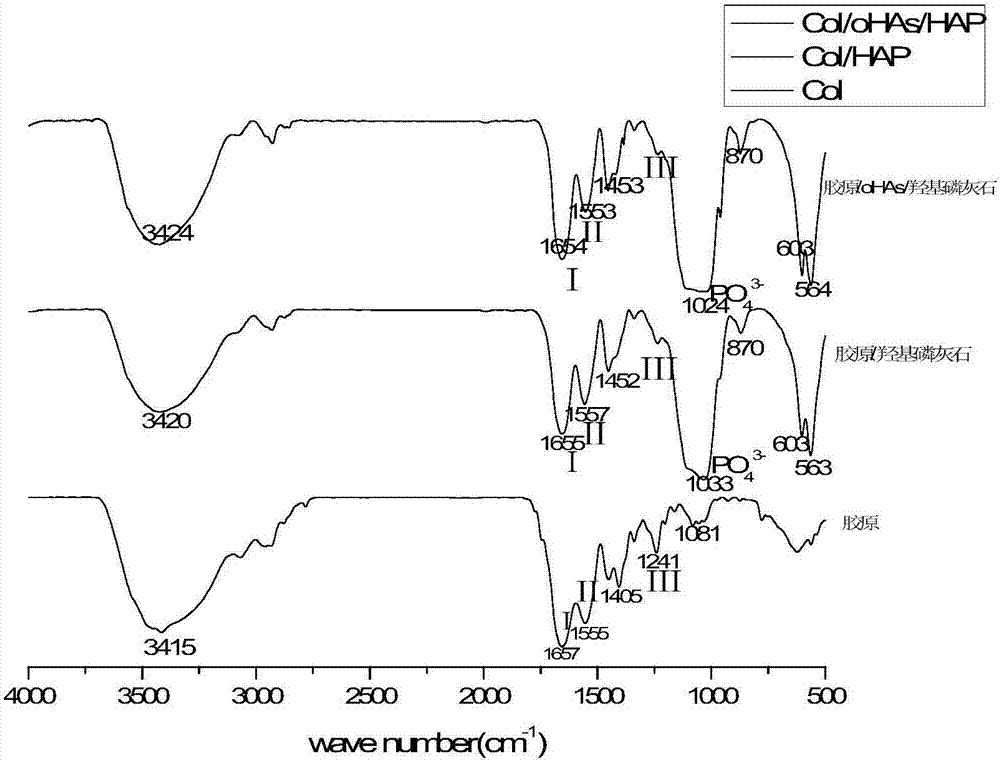

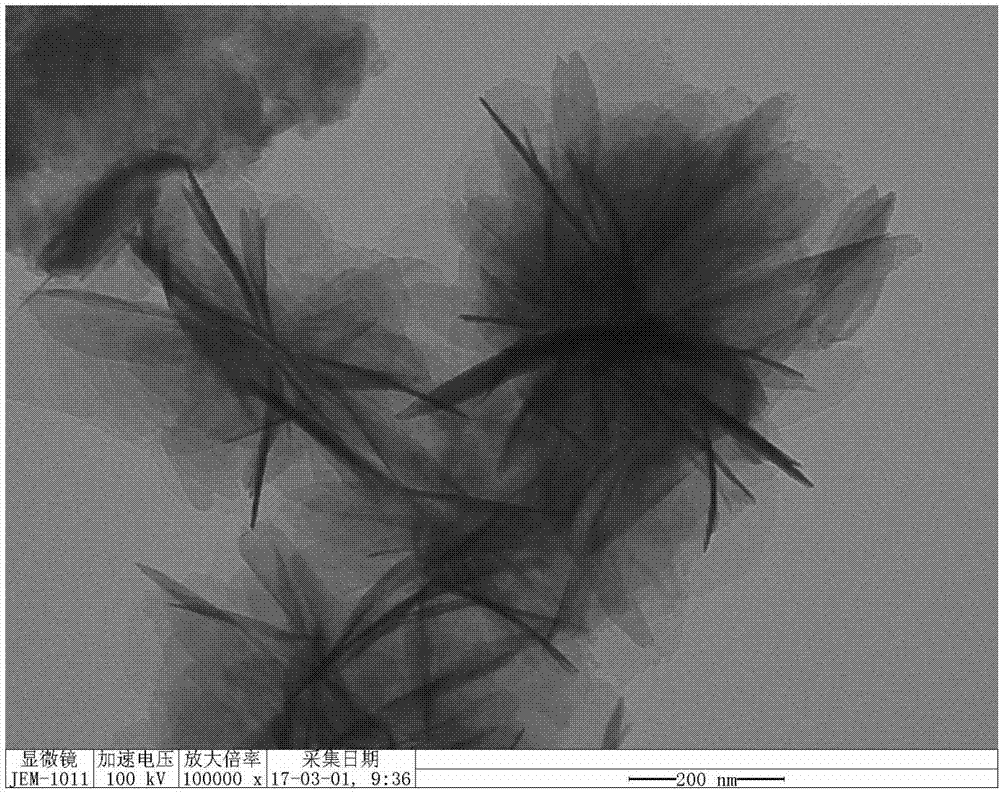

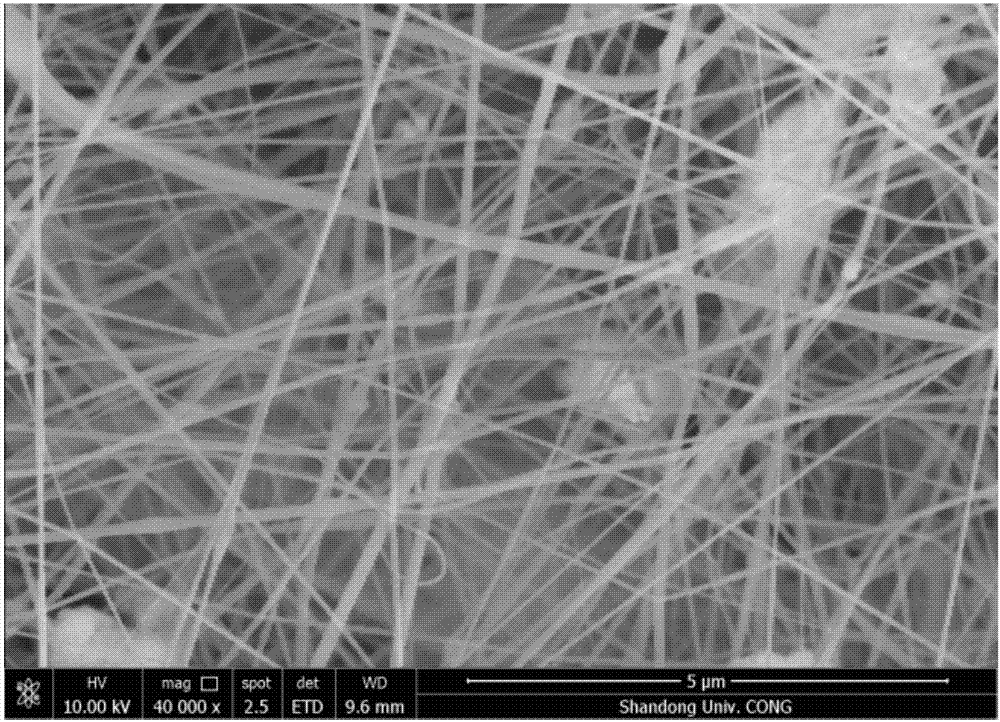

[0075] Preparation of Glycosylated Collagen Mineralization Composite (Col / oHAs / HAP):

[0076] Weigh 60 mg of the dried glycosylated collagen (Col / oHAs) prepared in Example 2 into 100 mL of HCl (concentration 0.01M) solution, and dissolve with magnetic stirring to obtain the Col / HA solution, and slowly add CaCl dropwise while stirring 2 (0.1M) solution 14mL, after mixing, let it stand for 10min, continue to stir and slowly add NaH 2 PO 4 (0.1M) solution 8.4mL (Ca:P=1.66), then slowly add 0.1M NaOH dropwise during stirring to adjust the pH of the system. When the pH is close to 6, the solution begins to appear turbid, and when the pH is about 6.2, the fluctuation is large. When the reaction is still in progress, continue to add NaOH dropwise until the pH of the system is 7, then continue to stir for 2 hours and keep the pH of the mineralization system unchanged; Centrifuge at 8000r / min for 3 times (8min / time), freeze-dry the sample at last, and grind to obtain hyaluronic acid-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com