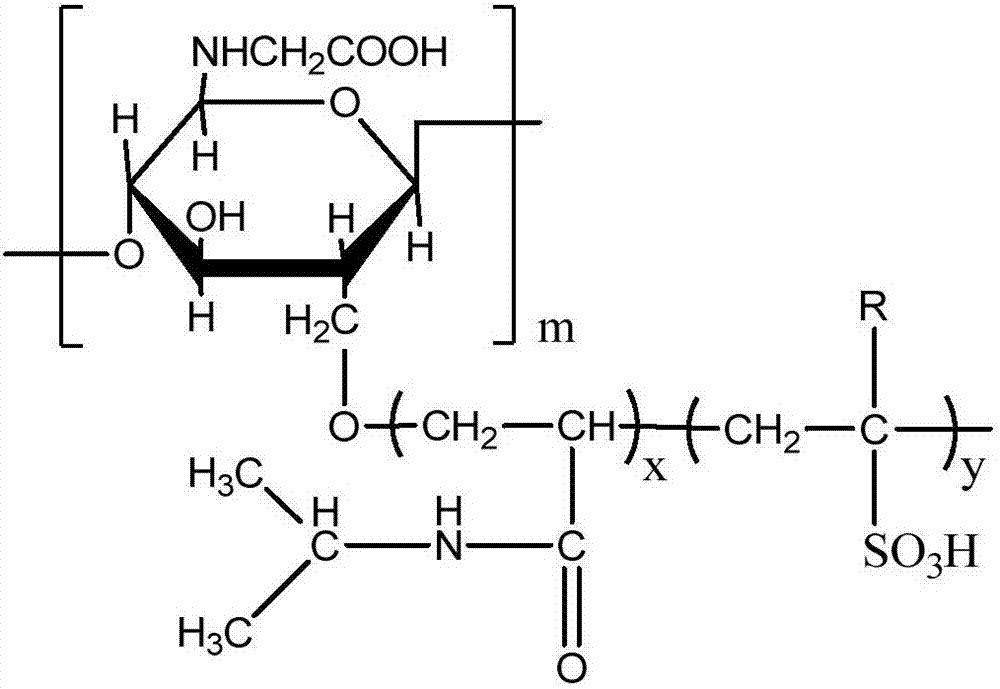

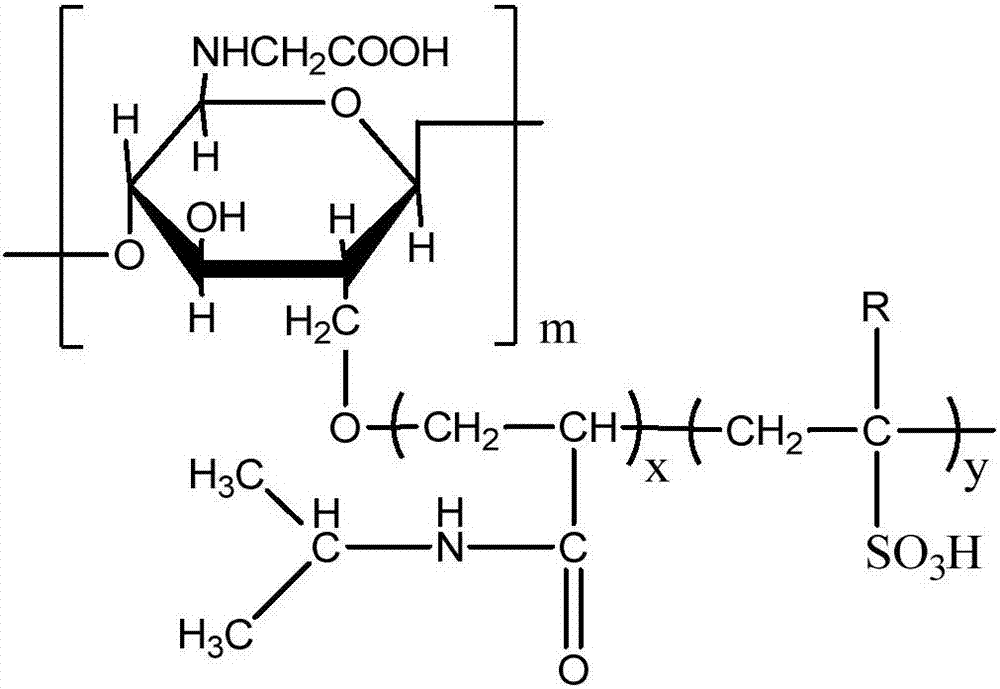

A high-functionality-degree amphiphilic copolymer metal chelating agent for crude oil and a preparing method thereof

A metal chelating agent, high-functionality technology, used in the treatment of hydrocarbon oil, refined hydrocarbon oil, petroleum industry, etc., can solve the problems of poor nickel and vanadium removal effect, non-compliance with environmental protection requirements, non-compliance with environmental protection, etc. Metal removal effect, green production process, good oil solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1: At room temperature, add 5g of carboxymethyl chitosan, 150g of deionized water, and 15g of N-isopropylacrylamide into the reaction kettle, dissolve evenly and pass nitrogen gas, and at 80°C under a nitrogen atmosphere, first Carry out microwave irradiation for 20 minutes, the power of microwave is 500W, after microwave irradiation, after adding 0.5g azobisisopropylimidazoline and 0.18g mercaptopropanol in the reaction kettle, dropwise add 250g mass fraction to be 10wt. % propylene sulfonic acid aqueous solution, dripped in 180 minutes, then reacted in microwave for 30 minutes after dripping, microwave power 400W. Cool down to room temperature after the reaction to obtain a light yellow transparent high-functionality amphiphilic copolymer crude oil metal chelating agent.

[0017] Take Oman Basra blended crude oil as test oil, its calcium content is 25.3ppm, iron content is 11.2ppm, nickel content is 16.7ppm, vanadium content is 69.3ppm, when the dosage of the ...

Embodiment 2

[0018] Example 2: At room temperature, add 10g of carboxymethyl chitosan, 100g of deionized water, and 6g of N-isopropylacrylamide into the reaction kettle, dissolve evenly, and pass nitrogen gas. At 90°C, under nitrogen atmosphere, first Carry out microwave irradiation for 5 minutes, the power of microwave is 90W, after microwave irradiation, add 0.1g azobiscyanovaleric acid and 0.5g mercaptopropionic acid to the reaction kettle, dropwise add 240g mass fraction to be 25wt.% The aqueous solution of methacrylic sulfonic acid was dripped in 60 minutes, and then microwaved for 10 minutes after the dripping, and the microwave power was 100W. Cool down to room temperature after the reaction to obtain a light yellow transparent high-functionality amphiphilic copolymer crude oil metal chelating agent.

[0019] Take Oman Basra mixed crude oil as test oil, its calcium content is 25.8ppm, iron content is 11.0ppm, nickel content is 16.7ppm, vanadium content is 69.6ppm, when the dosage of...

Embodiment 3

[0020] Example 3: At room temperature, add 24g of carboxymethyl chitosan, 300g of deionized water, and 60g of N-isopropylacrylamide into the reaction kettle, dissolve evenly and pass nitrogen gas, and at 70°C under nitrogen atmosphere, first Carry out microwave irradiation for 15 minutes, the power of microwave is 200W, after microwave irradiation, after adding 0.48g azobisisopropylimidazoline and 0.24g mercaptopropionic acid in the reaction kettle, dropwise add 120g mass fraction to be 20wt. % propylene sulfonic acid aqueous solution, dripped in 120 minutes, then reacted in microwave for 25 minutes after dripping, microwave power 600W. Cool down to room temperature after the reaction to obtain a light yellow transparent high-functionality amphiphilic copolymer crude oil metal chelating agent.

[0021] Take Oman Basra blended crude oil as test oil, its calcium content is 24.4ppm, iron content is 14.6ppm, nickel content is 17.1ppm, vanadium content is 64.3ppm, when the dosage o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com