Preparation method of high-purity tellurium diethyl

A diethyl tellurium, high-purity technology, applied in organic chemistry, etc., can solve the problems of drying and water removal, reducing the performance of CdHgTe thin film materials, and having no infrared detection performance, etc., achieving high yield, simple operation and safe method Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

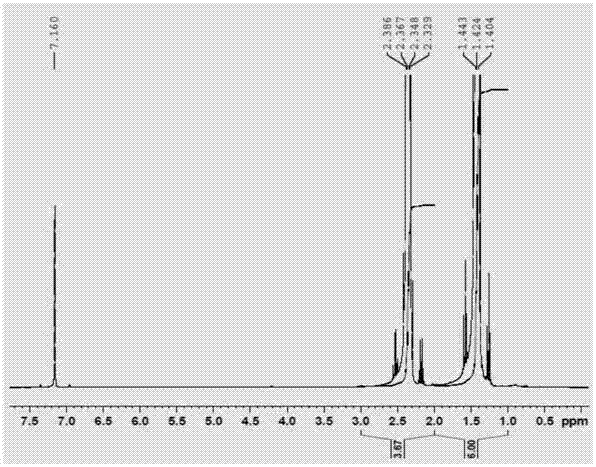

Image

Examples

preparation example Construction

[0021] The present invention proposes a kind of preparation method of high-purity diethyl tellurium, comprising the following steps:

[0022] S1: In a protective gas atmosphere, cool the tellurium tetrachloride solution to -20°C~-70°C, add ethyl magnesium halide dropwise to it, after the dropwise addition, raise the temperature to -60~0°C, and stir the reaction 1~5h, then raise the temperature to 10~30°C, continue to stir for 1~5h, and prepare the diethyl tellurium mixture;

[0023] S2: Under a protective gas atmosphere, the diethyl tellurium mixture is sequentially subjected to primary distillation, secondary distillation, and vacuum rectification to obtain diethyl tellurium with a purity of more than 5N;

[0024] The tellurium tetrachloride solution is an organic solution formed by dissolving tellurium tetrachloride in an organic solvent.

[0025] In the present invention, preferably, the organic solvent is any one or more of diethyl ether, tetrahydrofuran, toluene, and ben...

Embodiment 1

[0031] Reagent preparation: freshly prepared tellurium tetrachloride, stored under nitrogen environment; dry ethyl bromide: take 40g of calcium chloride and add it to 500ml of ethyl bromide, heat to reflux for 3h; dry tetrahydrofuran: use sodium to reflux tetrahydrofuran, as the indicator diphenylmethane When the ketone turns dark purple, distill off tetrahydrofuran and set aside.

[0032] Preparation of ethylmagnesium bromide: Add 22.08g (0.92mol) of magnesium chips and 250ml of tetrahydrofuran to a 1L three-necked flask, under nitrogen protection, heat the three-necked flask to 40°C, add dropwise 30ml of bromoethane containing 4.9g (0.045mol) The tetrahydrofuran solution is used as an initiator to speed up the reaction reflux, turn off the heating, adjust the drop rate slowly, continue to drop 270ml of tetrahydrofuran solution containing 93.2g (0.855mol) bromoethane, and finish adding within 1.5~2h, the dropwise addition is completed After that, turn on the heating, reflux f...

Embodiment 2

[0038] Reagent preparation: freshly prepare tellurium tetrachloride, store under nitrogen environment; dry ethyl iodide: take 40g of calcium chloride and add it to 500ml of ethyl iodide, heat to reflux for 3h.

[0039]Preparation of ethylmagnesium iodide: Add 22.08g (0.92mol) magnesium chips and 250ml ether to a 1L three-necked flask, under nitrogen protection, heat the three-necked flask to 40°C, add dropwise 30ml containing 7.01g (0.045mol) ethyl iodide To speed up the reaction reflux, turn off the heating, slow down the drop rate, continue to drop 270ml of ether solution containing 133.33g (0.855mol) ethyl iodide, and finish adding within 1.5~2h. After the dropwise addition, turn on Heating, reflux for 1h, set aside.

[0040] Preparation of diethyl tellurium: Under the protection of nitrogen, take 450 ml of ether and dissolve 62.65 g (0.23 mol) of tellurium tetrachloride to form a tellurium tetrachloride solution. The tellurium tetrachloride solution was cooled to -50°C, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com