Calcium hardness reducing method of recycle water of non-ferrous metallurgical acid waste water

A technology for acidic wastewater and reuse water, applied in the direction of water softening, etc., can solve the problems of equipment scaling, reduce calcium content in reuse water, etc., and achieve the effect of easy control of pH value and simple treatment method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

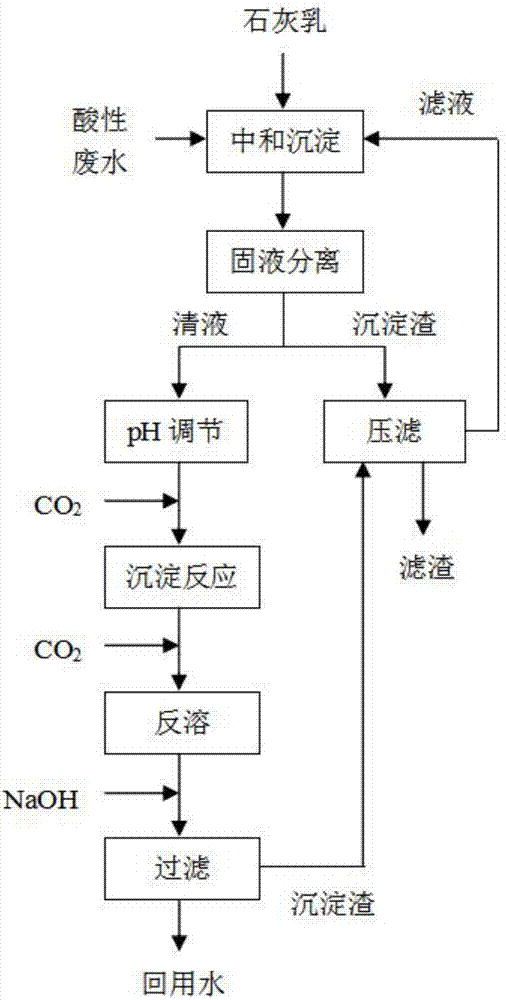

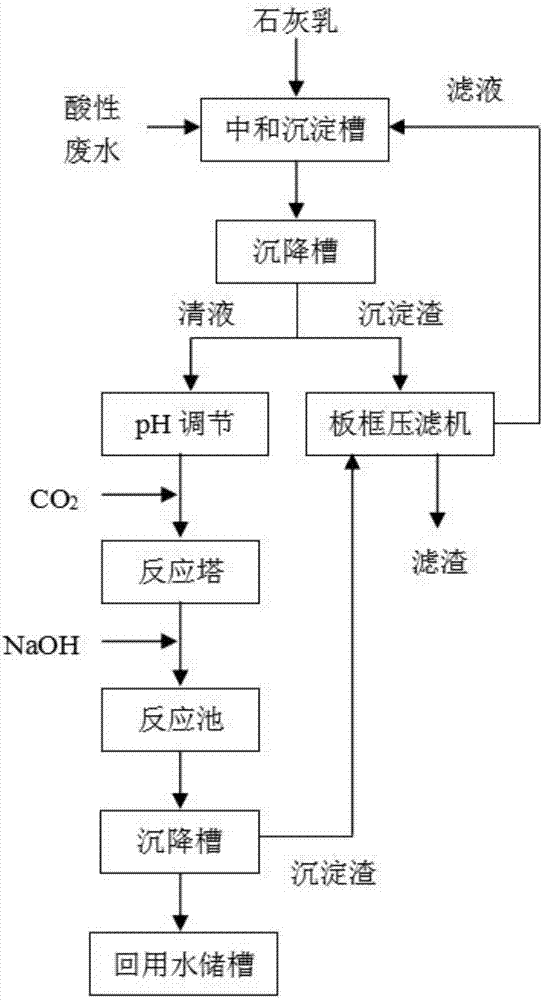

Method used

Image

Examples

Embodiment 1

[0044] The acid wastewater to be treated was taken from a factory in Yantai. Among them, the content of arsenic ions is 5000mg / L, the content of copper ions is 300mg / L, the content of lead ions is 20mg / L, the content of cadmium ions is 20mg / L, the content of zinc ions is 700mg / L, and the content of iron ions is 1600mg / L.

[0045] Wastewater and milk of lime are added to the neutralization sedimentation tank for stirring reaction. This process produces a large amount of precipitates, mainly calcium carbonate, calcium sulfate and heavy metal hydroxides. After this reaction step, most of the heavy metal ions of polluted acid are precipitated. .

[0046] The reacted mixture is transported to the conical settling tank for solid-liquid separation. The calcium hardness of the supernatant is 536mg / L, mainly containing calcium sulfate, and the precipitated residue containing heavy metals is sent to the plate and frame filter press for pressure filtration, and the filtrate is returned t...

Embodiment 2

[0051] Wastewater to be treated is also taken from the plant. Among them, the content of arsenic ions is 5500mg / L, the content of copper ions is 280mg / L, the content of lead ions is 15mg / L, the content of cadmium ions is 15mg / L, the content of zinc ions is 675mg / L, and the content of iron ions is 1700mg / L.

[0052] The treatment steps are the same as in Example 1. After neutralization and precipitation, the calcium ion content of the clear liquid is 320 mg / L, and after the reaction of carbon dioxide and sodium hydroxide, the calcium ion content of the recycled water is 31 mg / L.

[0053] Through the above-mentioned embodiment, the reaction of carbon dioxide and calcium ions reduces the calcium hardness, and fully meets the industrial production calcium ion content standard (≤200mg / L).

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com