Ultraviolet light-cured biomass epoxy acrylate prepolymer and synthesizing and application thereof

An epoxy acrylate, biomass technology, applied in the direction of modified epoxy resin adhesives, applications, epoxy resin coatings, etc., can solve the problems of poor light resistance and yellowing, high brittleness, poor flexibility, etc. Good flexibility and yellowing resistance, improved viscosity, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

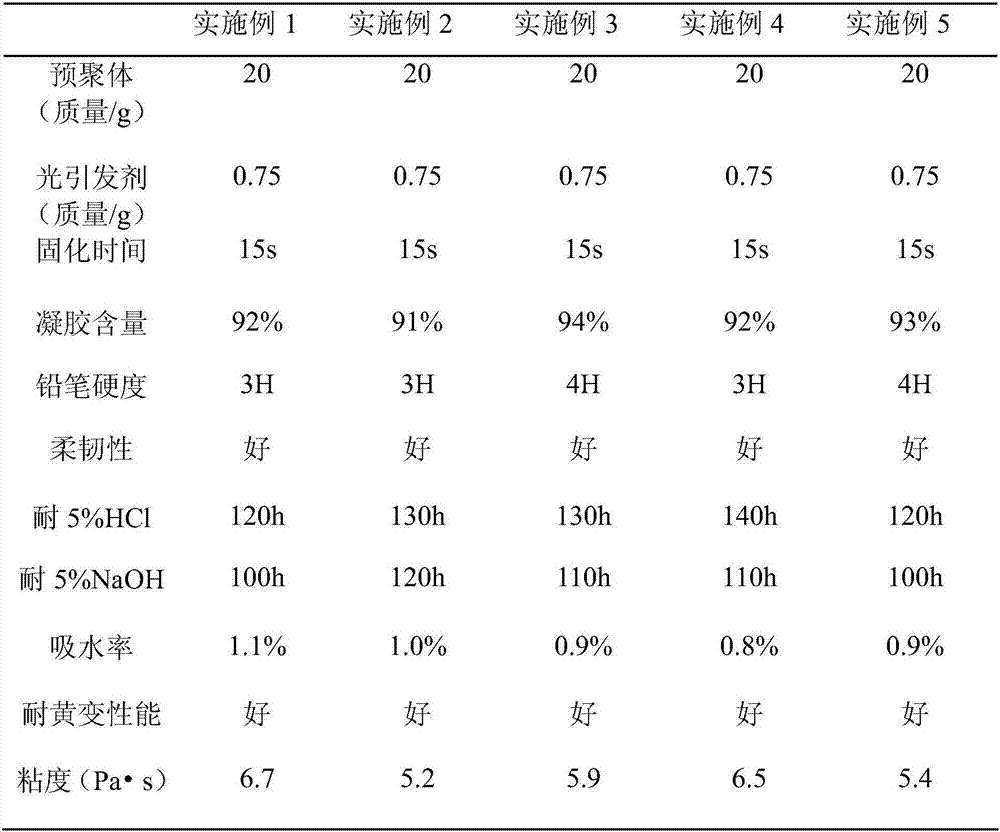

Examples

Embodiment 1

[0044] A kind of synthetic method of the biomass epoxy acrylate prepolymer of ultraviolet light curing, comprises the following steps:

[0045] 1. Mix 8.3g (0.028mol) of cardanol, 0.042g of zinc chloride and 1.4g (0.035mol) of sodium hydroxide, raise the temperature to 85°C under magnetic stirring, and add dropwise 4.4g (0.048mol) ) epichlorohydrin, the dropping time is 1.5h, maintained at a constant temperature of 105°C, reacted for 3h, cooled, washed with distilled water, filtered the organic phase with anhydrous sodium sulfate, and distilled under reduced pressure at 85°C to remove epichlorohydrin, Obtain cardanol glycidyl ether (I);

[0046] 2. Mix 5.3g (0.088mol) glacial acetic acid, 15.6g cyclohexane, 8.2g macroporous ion exchange resin D-120 with 9.8g (0.028mol) cardanol glycidyl ether (I), and keep the temperature at 60 ℃, add 15.0g (0.132mol) of hydrogen peroxide solution with a mass fraction of 30% dropwise, the dropwise addition time is 1.5h, react for 5h, cool, fi...

Embodiment 2

[0049] A kind of synthetic method of the biomass epoxy acrylate prepolymer of ultraviolet light curing, comprises the following steps:

[0050] 1. Mix 8.3g (0.028mol) of cardanol, 0.12g of aluminum chloride and 1.8g (0.032mol) of potassium hydroxide, and raise the temperature to 95°C under magnetic stirring, and dropwise add 3.8g (0.042mol) ) epichlorohydrin, dropwise for 1h, maintained at a constant temperature of 100°C, reacted for 2h, cooled, washed with distilled water, filtered the organic phase with anhydrous magnesium sulfate, distilled under reduced pressure at 75°C, removed epichlorohydrin, and obtained Cardanol glycidyl ether (I);

[0051] 2. Mix 5.9g (0.098mol) glacial acetic acid, 17.8g benzene, 11.8g macroporous ion exchange resin D113 and 9.8g (0.028mol) cardanol glycidyl ether (I), keep the temperature at 70°C, add dropwise 14.0g (0.124mol) of hydrogen peroxide solution with a mass fraction of 30% was added dropwise for 0.5h, reacted for 4h, cooled, filtered of...

Embodiment 3

[0054] A kind of synthetic method of the biomass epoxy acrylate prepolymer of ultraviolet light curing, comprises the following steps:

[0055] 1. Mix 8.3g (0.028mol) of cardanol, 0.083g of ferric chloride and 1.2g (0.030mol) of sodium hydroxide, raise the temperature to 90°C under magnetic stirring, and add dropwise 4.1g (0.044mol) ) epichlorohydrin, the dropping time is 0.5h, maintained at a constant temperature of 95°C, reacted for 3h, cooled, washed with distilled water, filtered the organic phase with anhydrous sodium sulfate, and distilled under reduced pressure at 80°C to remove epichlorohydrin, Obtain cardanol glycidyl ether (I);

[0056] 2. Mix 5.6g (0.093mol) glacial acetic acid, 16.3g cyclohexane, 9.1g macroporous ion exchange resin D-120 with 9.8g (0.028mol) cardanol glycidyl ether (I), and keep the temperature at 65 ℃, add 14.4g (0.127mol) of hydrogen peroxide solution with a mass fraction of 30% dropwise, the dropwise addition time is 1h, react for 6h, cool, fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com