Method for preparing hollow porous Na2MnPO4F/C nanometer fiber positive electrode material

A nanofiber, cathode material technology, applied in nanotechnology, nanotechnology, fiber processing, etc., can solve the problems of difficult to obtain electrochemical performance, unsatisfactory modification effect, low electronic conductivity and ionic conductivity, etc. The effect of improving cycle performance, enhancing electronic conductivity, and improving rate capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

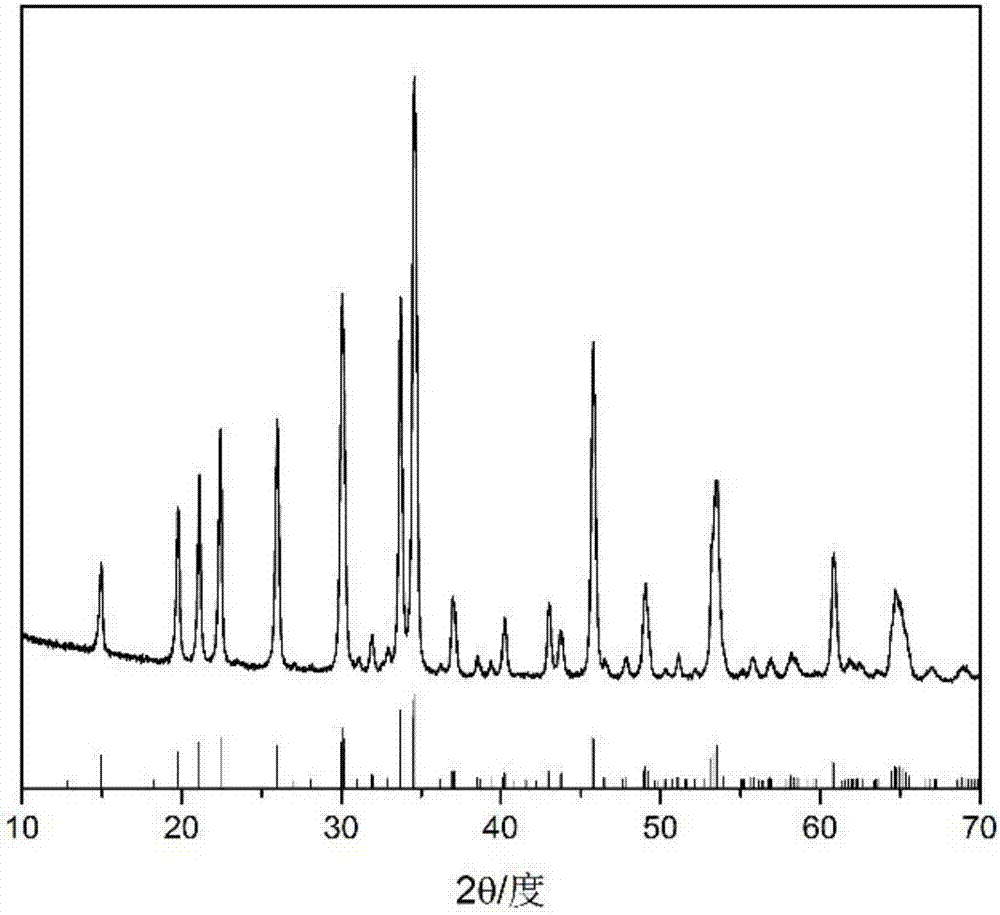

Embodiment 1

[0038] a. Mole ratio Na + :Mn 2+ :PO 4 3- :F - =2.05:1:1:1 Weigh sodium fluoride, sodium dihydrogen phosphate and manganese acetate, use deionized water as solvent, stir at room temperature until completely dissolved, add molar ratio of 1:1.2 (sodium manganese fluorophosphate: Oxalic acid), then add polyvinyl alcohol with a mass ratio of 7:1 (sodium manganese fluorophosphate: high molecular weight polymer) and an average molecular weight of 6000, and continue to stir until a uniform spinning solution A is formed;

[0039]b. select mineral oil as spinning solution B;

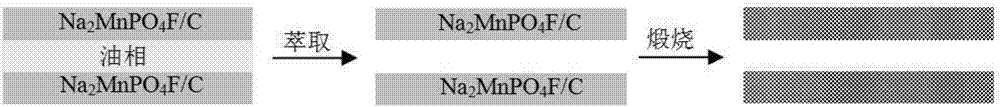

[0040] c. Na 2 PPML 4 F Spinning solution A and mineral oil spinning solution B are drawn into the syringe respectively, and the coaxial spinning needle is installed. The inner and outer diameters of the needle are 0.3mm and 0.5mm respectively. It is 12Kv, and the spinning speed is 0.15mm / min, and the coaxial nanofiber precursor is prepared;

[0041] d. Place the coaxial nanofiber in the extractant n-hexa...

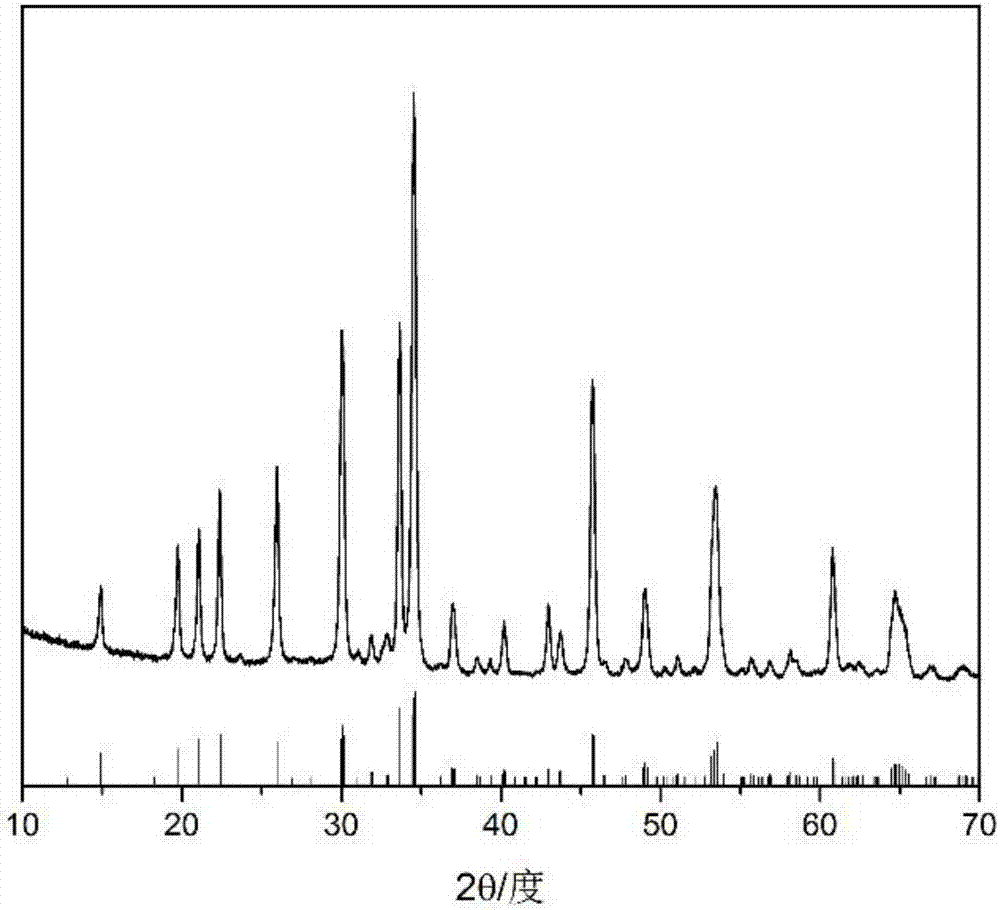

Embodiment 2

[0044] a. Mole ratio Na + :Mn 2+ :PO 4 3- :F - =2:1.05:1:1 Weigh sodium fluoride, sodium dihydrogen phosphate and manganese carbonate, use ethanol as solvent, stir at room temperature until completely dissolved, add molar ratio of 0.9:1.1 (sodium manganese fluorophosphate: oxalic acid) oxalic acid, then add polyvinyl alcohol with a mass ratio of 6.9:1 (sodium manganese fluorophosphate: high molecular weight polymer) and an average molecular weight of 6000, and continue to stir until a uniform spinning solution A is formed.

[0045] b. select mineral oil as spinning solution B;

[0046] c. Na 2 PPML 4 F Spinning solution A and mineral oil spinning solution B are drawn into the syringe respectively, and the coaxial spinning needle is installed. It is 12Kv, and the spinning speed is 0.05mm / min, and the coaxial nanofiber precursor is prepared;

[0047] d. Place the coaxial nanofiber in the extractant n-hexane to remove the oil phase, and dry to obtain the hollow nanofiber ...

Embodiment 3

[0050] a. Mole ratio Na + :Mn 2+ :PO 4 3- :F - =2:1:1.05:1 Weigh ammonium fluoride, disodium hydrogen phosphate and manganese carbonate, use ethanol as solvent, stir at room temperature until completely dissolved, add molar ratio of 1:1.2 (sodium manganese fluorophosphate: citric acid ), then add polyacrylonitrile with a mass ratio of 7.1:1.1 (sodium manganese fluorophosphate: polymer) and an average molecular weight of 100,000, and continue stirring until a uniform spinning solution A is formed;

[0051] b. select mineral oil as spinning solution B;

[0052] c. Na 2 PPML 4 F Spinning solution A and mineral oil spinning solution B are extracted into the syringe respectively, and the coaxial spinning needle is installed. Be 10Kv, spinning speed is 0.15mm / min, prepares coaxial nanofiber precursor;

[0053] d. Place the coaxial nanofiber in the extractant n-hexane to remove the oil phase, and dry to obtain the hollow nanofiber precursor;

[0054] e. Place the collected c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com