Blood purification adsorbent with embedding material and preparation method of blood purification adsorbent

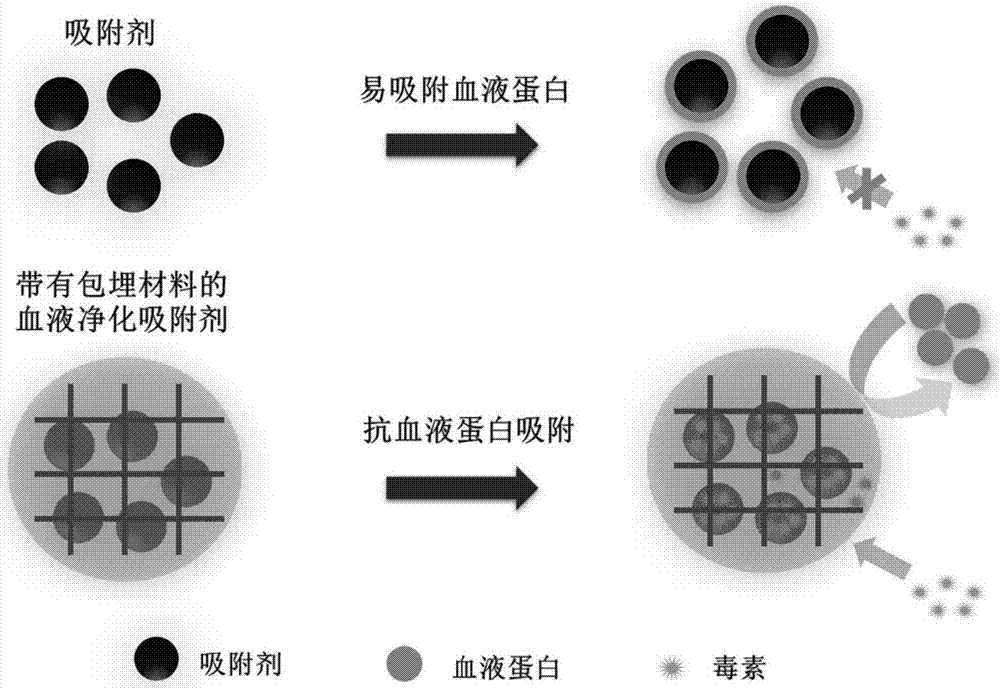

An embedding material and blood purification technology, applied in chemical instruments and methods, blood circulation treatment, inorganic chemistry, etc., can solve the problems of low adsorption efficiency, poor biocompatibility, etc., and achieve retention of adsorption performance, avoid leakage, excellent resistance The effect of protein adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

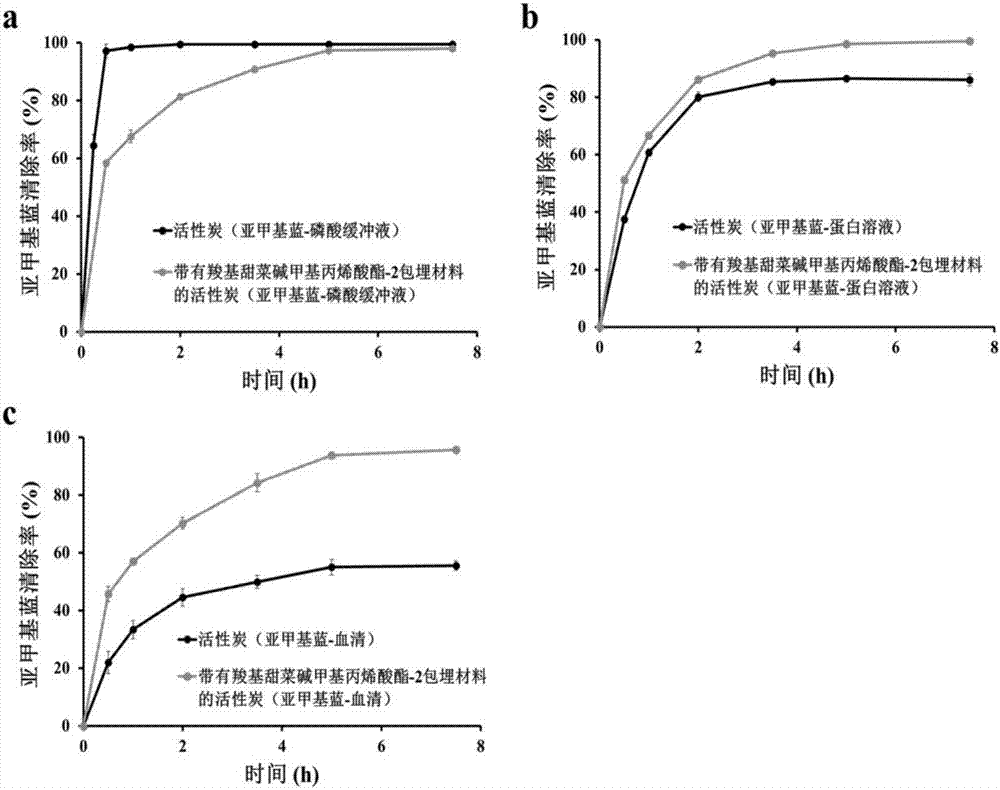

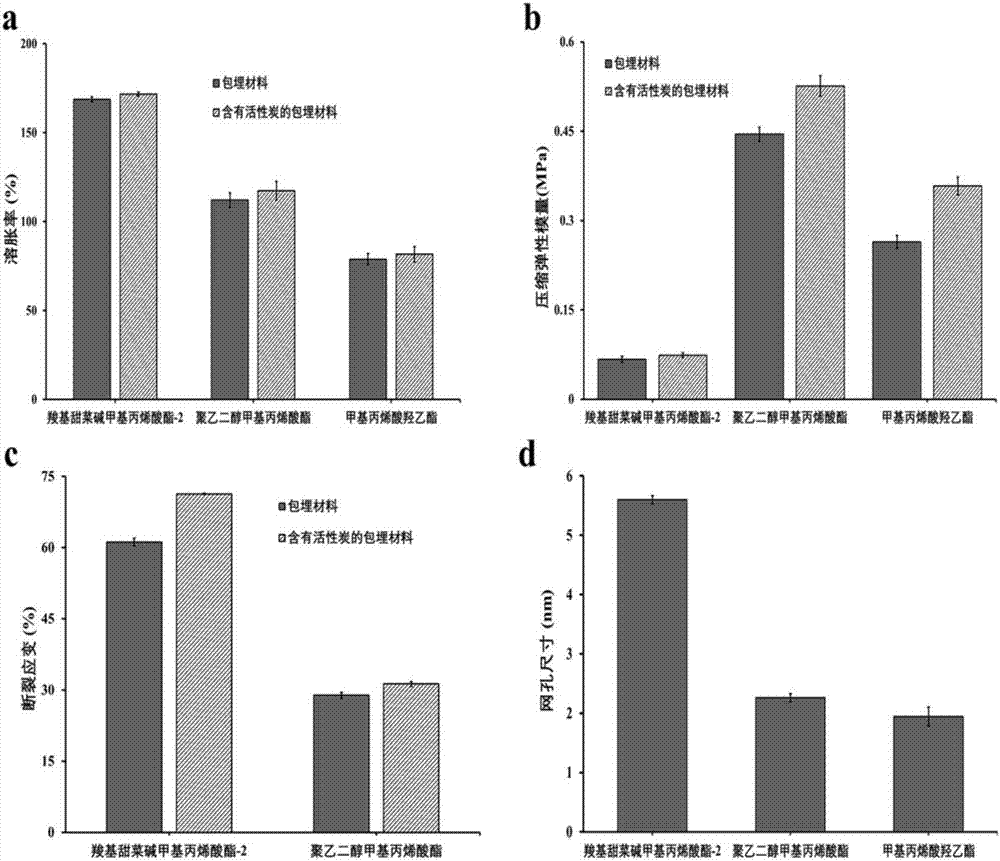

[0051] Preparation of activated carbon with 2-methacryloyloxyethyl phosphorylcholine embedding material

[0052] Weigh 256 mg of 2-methacryloyloxyethyl phosphorylcholine, 2.52 μL of triethylene glycol dimethacrylate, 6 μL of 2-hydroxy-2-methyl-1-phenyl-1-propanone and dissolve in 1 mL Phosphate buffer solution, the mass percentages of the above components are as follows:

[0053]

[0054]

[0055] Add 61 mg of activated carbon (the mass of activated carbon is 24% of the zwitterionic monomer) to the above solution, and stir to form a uniform mixed solution.

[0056] Activated carbon with 2-methacryloyloxyethylphosphorylcholine embedding material was prepared by template method. The preparation process was to add the mixed solution containing activated carbon into the pouring template made of glass slide and Teflon spacer , and reacted in an ultraviolet cross-linking apparatus for 5 minutes to cross-link and embed 2-methacryloyloxyethyl phosphorylcholine on the surface of...

Embodiment 2

[0058] Preparation of resin with carboxybetaine methacrylate-1 (CBMA-1) embedding material

[0059] Weigh 692 mg of carboxybetaine methacrylate-1 (CBMA-1), 4.29 μL of polyethylene glycol diglycidyl ether, 1 mg of ammonium persulfate, 2 μL of tetramethylethylenediamine dissolved in 1 mL of 1M chloride In the sodium solution, the mass percentages of the above-mentioned components are as follows:

[0060]

[0061] Add 346 mg of H103 resin (the mass of the resin is 50% of the mass of the zwitterionic monomer) to the above solution, and stir to form a uniform mixed solution.

[0062] The resin with carboxybetaine methacrylate-1 (CBMA-1) embedding material is prepared by microfluidic method. The preparation process is to use the mixed solution containing resin as the dispersed phase, and corn oil (containing a volume ratio of 1 % tetramethylethylenediamine) as the continuous phase; the injection flow rate of the dispersed phase is 10 μL / min, and the injection flow rate of the co...

Embodiment 3

[0064] Preparation of activated carbon with carboxybetaine methacrylamide embedding material

[0065] Weigh 194 mg of carboxybetaine methacrylamide, 41 mg of N,N'-dimethylacrylamide cystine, and 5 mg of azobisisoheptanonitrile and dissolve them in 1.7 mL of distilled water. The mass percentages of the above components are as follows:

[0066]

[0067] Add 45 mg of activated carbon (the mass of activated carbon is 23% of the zwitterionic monomer) to the above solution, and stir to form a uniform mixed solution.

[0068] Adopt the method for inverse emulsion polymerization to prepare the gac with carboxybetaine methacrylamide embedding material, the preparation process is that the mixed solution containing gac is added to the acetonitrile containing 4.2g of Tween 80 and 4.8g of Span 80 In alkanes (120mL); the solution was mixed with high-speed stirring to form a microemulsion, nitrogen deoxidation was carried out at 4°C, and stirring was carried out under nitrogen protection ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com