Electrochemical doping method for electrochromic thin film

An electrochromic and electrochemical technology, which is applied in the direction of electrolytic inorganic material coating, device for coating liquid on the surface, ion implantation plating, etc. Preparation of thin films and other issues to achieve the effect of reducing doping costs, simplifying the experimental process, and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

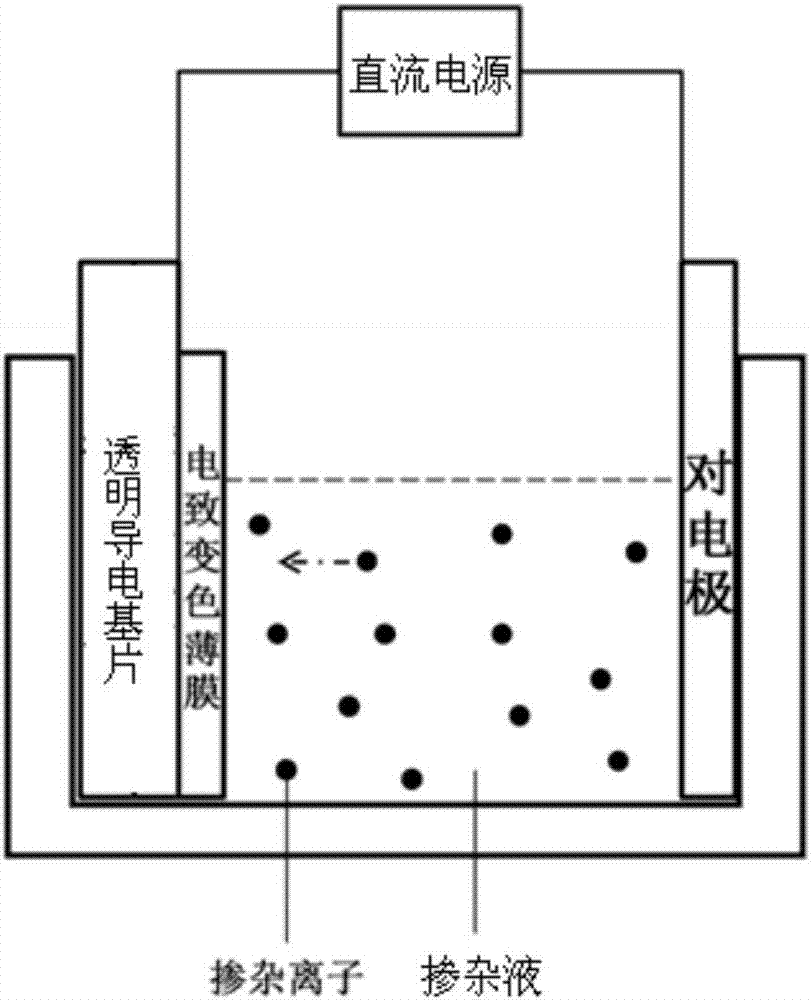

[0017] The present invention will be described in further detail below. see figure 1 , an electrochemical doping method for an electrochromic thin film, characterized in that the steps of electrochemical doping are as follows:

[0018] 1. Preparation of electrochromic thin film: Electrochromic thin film is prepared on transparent conductive substrate by magnetron sputtering method, spin coating method, electrodeposition method, spray method or pulling method. The electrochromic thin film material includes tungsten oxide, Molybdenum oxide, niobium oxide, nickel oxide, vanadium pentoxide, iridium oxide, cobalt oxide, nickel tungsten oxide, cerium oxide, tantalum oxide, Prussian blue, polyaniline, polypyrrole, polythiophene, polybenzazole, polyfuran or poly One or a mixture of carbazoles; the prepared electrochromic film is attached to a transparent conductive substrate;

[0019] 2. Preparation of doping solution: Dissolve one or more soluble salts containing H, Li, Na, K, Mg, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com