Water-proof and dehumidifying modified antirust agent for ships and preparation method of water-proof and dehumidifying modified antirust agent

A technology of anti-rust agent for ships, which is applied in the direction of anti-corrosion coatings, coatings, polyurea/polyurethane coatings, etc. It can solve the problems that the equipment is easy to rust, and the waterproof performance and dehumidification performance of anti-rust agents cannot meet the needs of ships.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

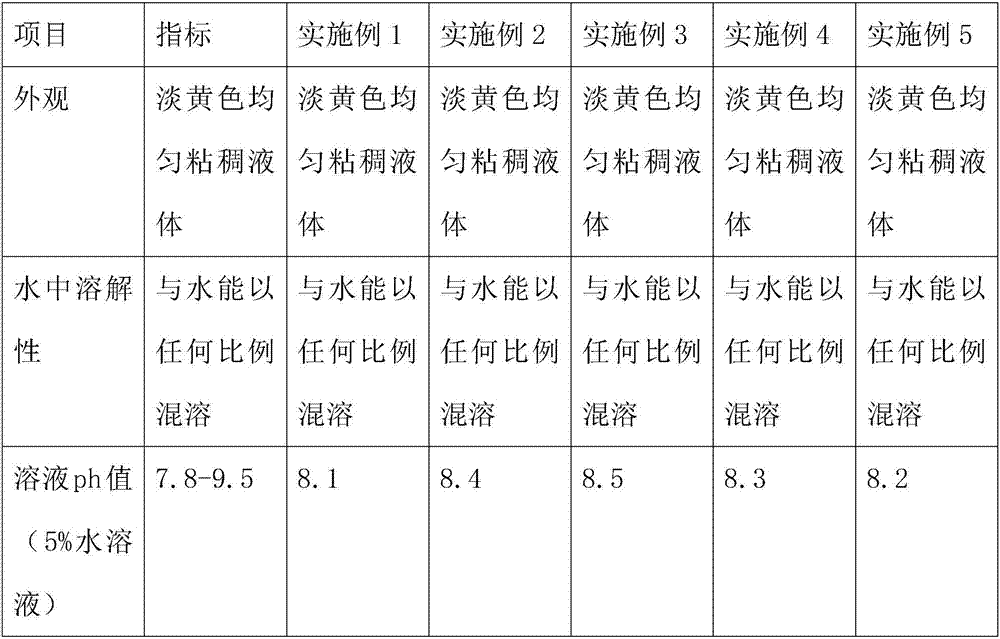

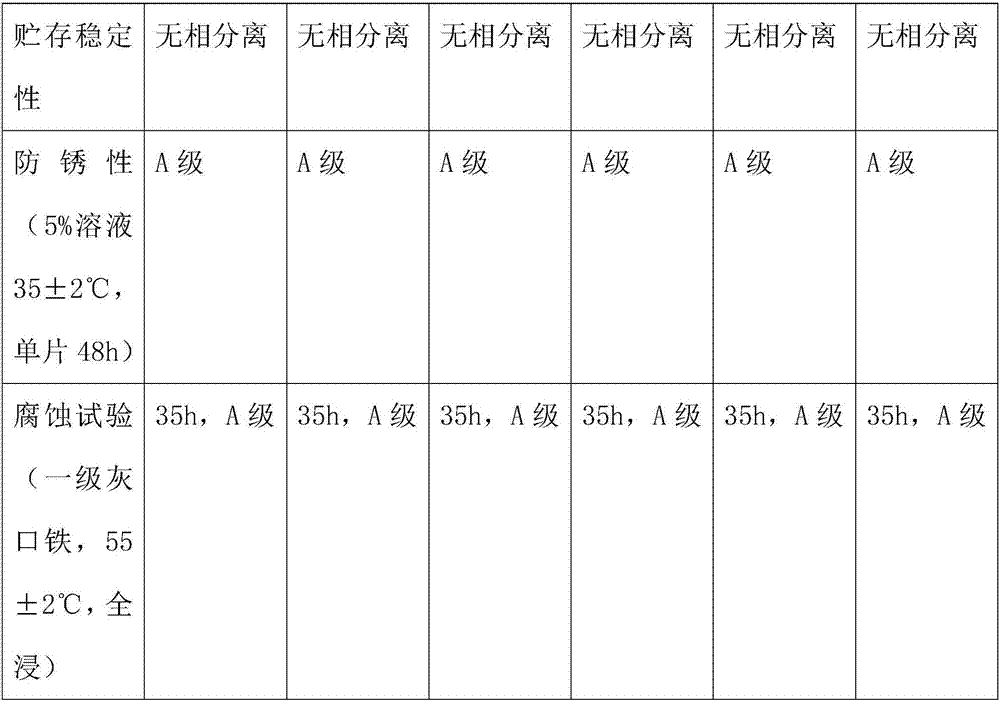

Examples

Embodiment 1

[0015] The waterproof and dehumidifying modified rust preventive agent for ships proposed by the present invention comprises, in parts by weight, raw materials: 6 parts of calcium sulfonate, 6 parts of amine-soluble quaternary ammonium copper, 2 parts of sodium hexametaphosphate, and 4.5 parts of glutaraldehyde , 2.5 parts of carbon nanotubes, 3.5 parts of sodium borohydride, 6 parts of polyvinyl alcohol, 6 parts of sodium sulfonate, 4 parts of zinc phosphate, 4 parts of zinc powder, 2.5 parts of zinc stearate, 4 parts of magnesium stearate, silane 7 parts of coupling agent KH-5707, 2.5 parts of water-based polyurethane, 4 parts of azobisisobutyronitrile, 3.5 parts of benzotriazole, 4.5 parts of diamine hydrogen phosphate, 2.5 parts of triethanolamine, 4.5 parts of fatty acid, trimethylol 5 parts of propane, 6.5 parts of sodium dialkyldithiocarbamate, 3.5 parts of polyisobutylene succinimide, 3.5 parts of methyl benzoate, 6 parts of polytetrafluoroethylene, 4.5 parts of octadec...

Embodiment 2

[0021] The water-proof and dehumidifying modified rust inhibitor for ships proposed by the present invention includes, in parts by weight, raw materials: 4 parts of calcium sulfonate, 8 parts of amine-soluble quaternary ammonium copper, 1 part of sodium hexametaphosphate, and 6 parts of glutaraldehyde , 1 part of carbon nanotubes, 5 parts of sodium borohydride, 3 parts of polyvinyl alcohol, 9 parts of sodium sulfonate, 3 parts of zinc phosphate, 6 parts of zinc powder, 1 part of zinc stearate, 5 parts of magnesium stearate, silane 5 parts of coupling agent KH-570, 4 parts of water-based polyurethane, 2 parts of azobisisobutyronitrile, 5 parts of benzotriazole, 3 parts of diamine hydrogen phosphate, 4 parts of triethanolamine, 3 parts of fatty acid, trimethylol 8 parts of propane, 4 parts of sodium dialkyldithiocarbamate, 5 parts of polyisobutylene succinimide, 1 part of methyl benzoate, 9 parts of polytetrafluoroethylene, octadecyltrimethylammonium chloride 3 parts, 5 parts of...

Embodiment 3

[0027] The waterproof and dehumidifying modified rust preventive agent for ships proposed by the present invention comprises, in parts by weight, raw materials: 8 parts of calcium sulfonate, 4 parts of amine-soluble quaternary ammonium copper, 3 parts of sodium hexametaphosphate, and 3 parts of glutaraldehyde , 4 parts of carbon nanotubes, 2 parts of sodium borohydride, 9 parts of polyvinyl alcohol, 3 parts of sodium sulfonate, 5 parts of zinc phosphate, 2 parts of zinc powder, 4 parts of zinc stearate, 3 parts of magnesium stearate, silane 9 parts of coupling agent KH-570, 1 part of water-based polyurethane, 6 parts of azobisisobutyronitrile, 2 parts of benzotriazole, 6 parts of diamine hydrogen phosphate, 1 part of triethanolamine, 6 parts of fatty acid, trimethylol 2 parts of methyl propane, 9 parts of sodium dialkyldithiocarbamate, 2 parts of polyisobutylene succinimide, 6 parts of methyl benzoate, 3 parts of polytetrafluoroethylene, octadecyltrimethylammonium chloride 6 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com