Composite positive electrode material for long-lifetime thermal battery and preparation method of composite positive electrode material

A composite positive electrode material and thermal battery technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of no molybdenum disulfide and its composite materials, and achieve the effects of flat discharge platform, long discharge time, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

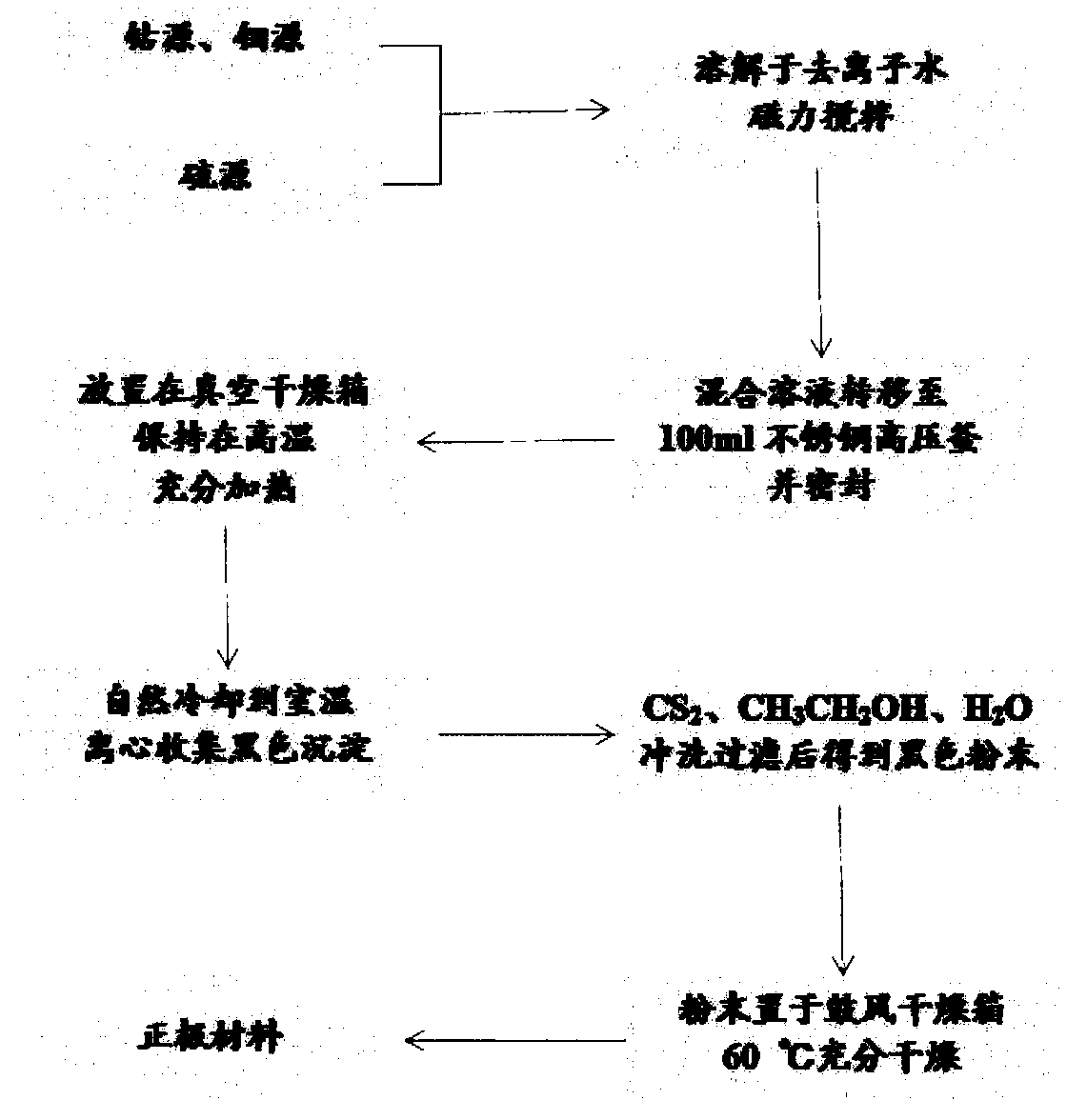

[0022] 1) Precursor preparation, weighing the cobalt source, molybdenum source, and sulfur source according to the stoichiometric ratio, and adding a surfactant to the beaker at the same time, fully magnetic stirring to mix the raw materials evenly, adding the reducing agent, and set aside. In the process of precursor configuration, the cobalt source is cobalt chloride hexahydrate (CoCl2 6H2O), the sulfur source is sodium thiosulfate pentahydrate (Na2S2O3 5H2O), thioacetamide (CH3CSNH2) and thiourea (H2NCSNH2), The molybdenum source is ammonium molybdate and sodium molybdate, and the molar ratio of cobalt to molybdenum is 0, 1 / 9-9. The additives include a surfactant and a reducing agent, wherein the surfactant is sodium dodecylbenzenesulfonate, and the reducing agent is citric acid monohydrate.

[0023] 2) Hydrothermal synthesis, the homogeneously mixed precursor was transferred to a 100 ml Teflon-lined stainless steel autoclave. After the stainless steel high-pressure reacti...

Embodiment 1

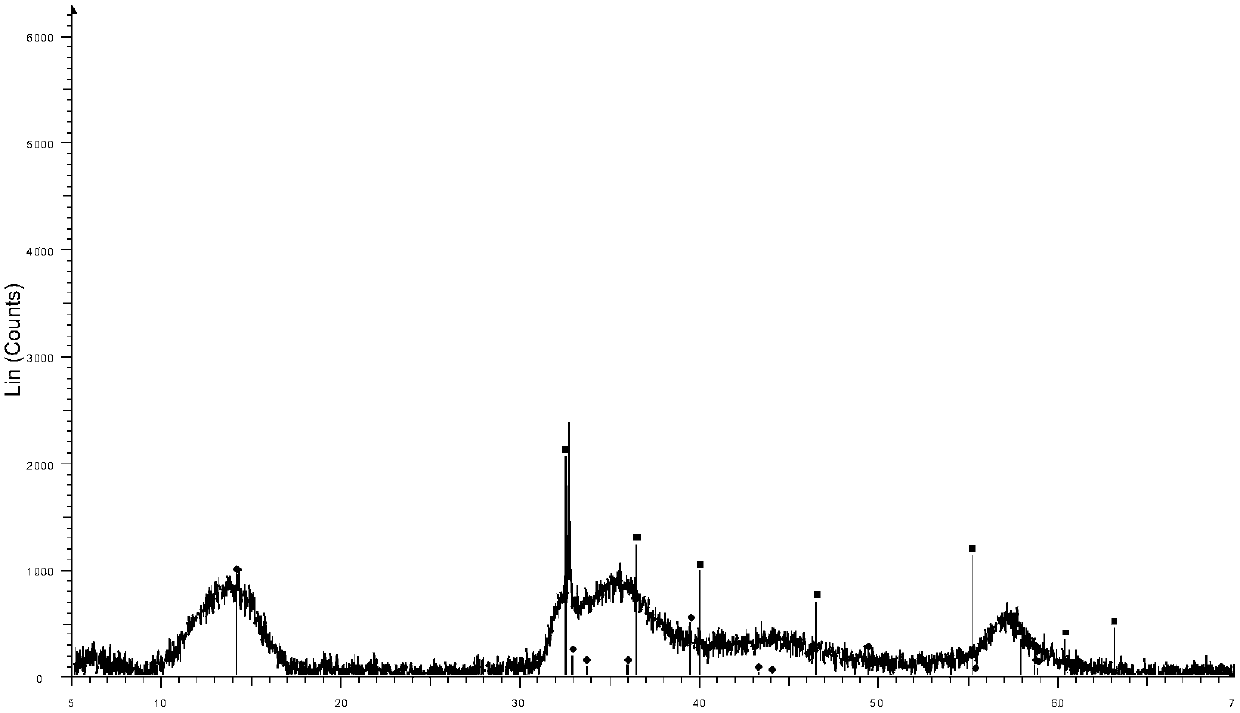

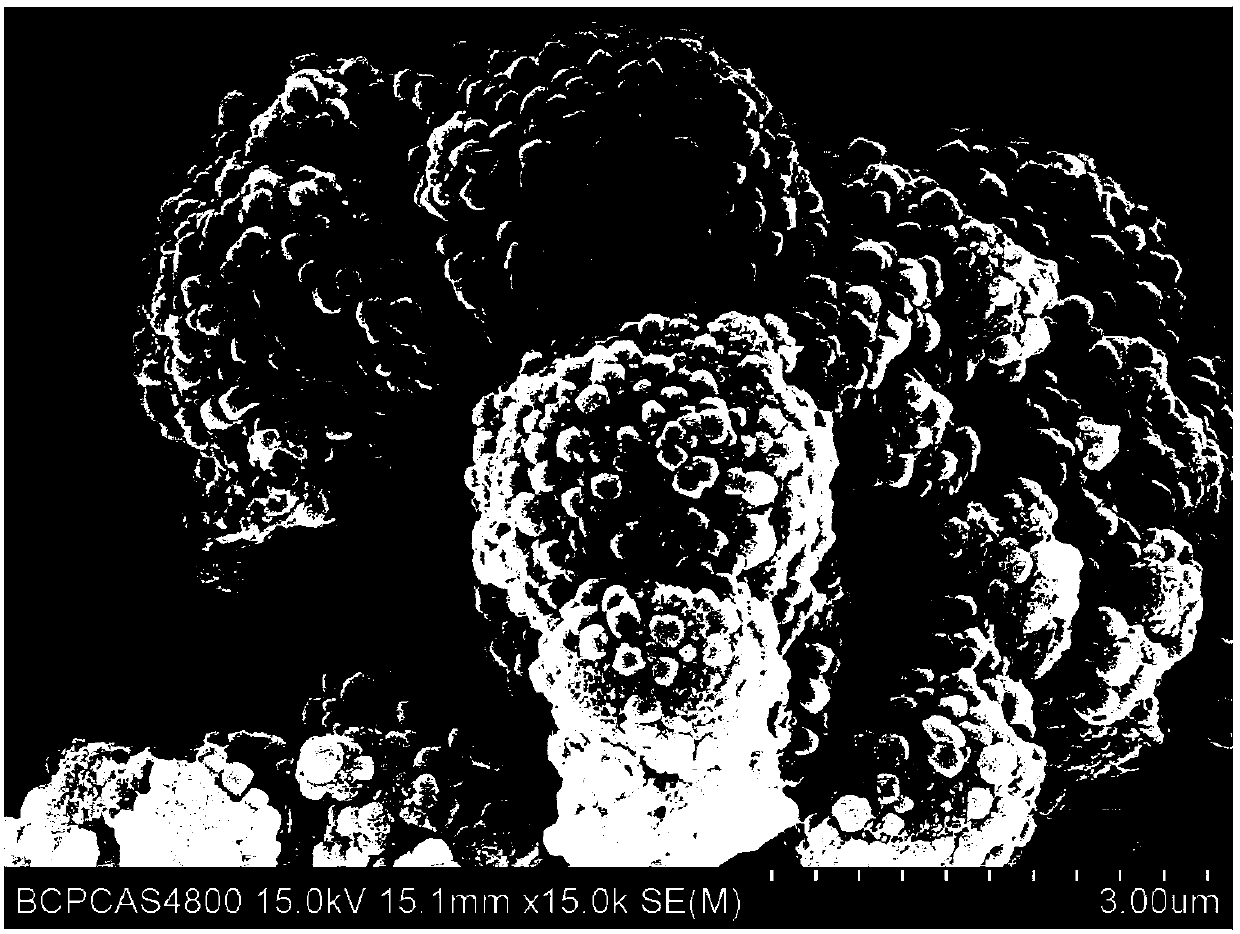

[0028] 0.8828 g of ammonium molybdate and 2.42 g of sodium thiosulfate pentahydrate were dissolved in 60 ml of deionized water, 0.2 g of citric acid monohydrate was added as a reducing agent and magnetically stirred for 30 minutes, then the mixed solution was transferred to a 100 ml Teflon liner stainless steel autoclave. After the stainless steel autoclave is sealed, it is placed in a vacuum drying oven, kept at 200°C for 22 hours, and then naturally cooled to room temperature. The black precipitate was collected by centrifugation, washed several times with carbon disulfide, ethanol and distilled water and filtered to obtain a black powder. Finally, the powder was dried at 60°C for 12 hours. In this embodiment, lithium-silicon alloy powder, self-made all-lithium electrolyte separator powder, and self-made positive electrode powder are used to carry out sheeting of thermal battery single cells. The positive electrode material is discharged at 450° C., the first discharge pla...

Embodiment 2

[0030] 0.6050 g of sodium molybdate, 0.5984 g of cobalt sulfide hexahydrate and 1.6257 g of thioacetamide were dissolved in 60 ml of deionized water, and 0.2 g of citric acid monohydrate was added as a reducing agent and magnetically stirred for 30 minutes, then the mixed solution was transferred to 100 ml Teflon-lined stainless steel autoclave. After the stainless steel autoclave is sealed, it is placed in a vacuum drying oven, kept at 180°C for 24 hours, and then naturally cooled to room temperature. The black precipitate was collected by centrifugation, washed several times with carbon disulfide, ethanol and distilled water and filtered to obtain a black powder. Finally, the powder was dried at 60°C for 12 hours. In this embodiment, lithium-silicon alloy powder, self-made all-lithium electrolyte separator powder, and self-made positive electrode powder are used to carry out sheeting of thermal battery single cells. The positive electrode material is discharged at 450° C.,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com