3D morphology CeO2/TiO2 catalyst preparation method

A catalyst and morphology technology, applied in the field of cerium oxide and titanium dioxide heterojunction photocatalysts, can solve the problems of low utilization rate of sunlight and achieve the effects of wide adjustable range of parameters, strong repeatability, and simple process and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A 3D shape of CeO 2 / TiO 2 Catalyst preparation method, comprises the steps:

[0028] (1) Add urea, cetyltrimethylammonium bromide (CTAB), and cerium nitrate to ethylene glycol, stir to dissolve, add tetrabutyl titanate, and stir to form a homogeneous solution. Then add deionized water dropwise while stirring in the above system until a transparent gel is formed;

[0029] (2) Put the above gel into a polytetrafluoroethylene-lined stainless steel autoclave, and conduct a hydrothermal reaction at 150°C for 24 hours. After the reaction, wash the precipitated product with deionized water until the pH of the washing solution is neutral, and then Dry at 80° C. for more than 10 hours to obtain the target cerium oxide / titanium dioxide composite nanomaterial.

[0030] (3) The above-mentioned dried sample was calcined at 400 °C for 2 h to remove residual organic matter to obtain 3D CeO 2 / TiO 2 composite nanomaterials.

Embodiment 2

[0034] A 3D shape of CeO 2 / TiO 2 Catalyst preparation method, comprises the steps:

[0035] (1) Add urea, cetyltrimethylammonium bromide (CTAB), and cerium nitrate to ethylene glycol, stir to dissolve, add liquid phase titanium source (isopropyl titanate), and stir to form a homogeneous solution. Then, deionized water was added dropwise to the above system while stirring until a transparent gel was formed.

[0036](2) Put the above gel into a polytetrafluoroethylene-lined stainless steel autoclave for hydrothermal reaction at 200 °C for 8 h. After the reaction, the precipitated product was washed with deionized water until the pH of the washing solution was neutral, and then dried at 80° C. for more than 10 h. Drying treatment is carried out to obtain the target cerium oxide / titania composite nanomaterial.

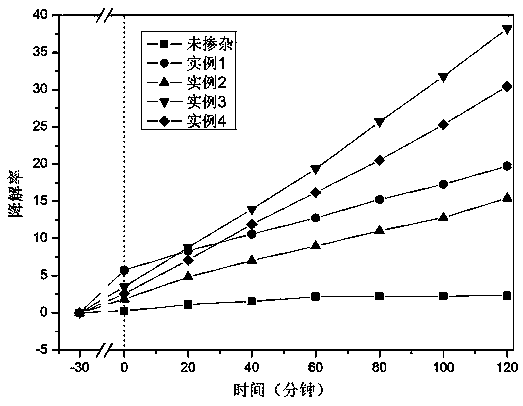

[0037] (3) The above-mentioned dried sample was calcined at 400 °C for 2 h to remove residual organic matter to obtain 3D CeO 2 / TiO 2 composite nanomaterials, see ...

Embodiment 3

[0041] A 3D shape of CeO 2 / TiO 2 Catalyst preparation method, comprises the steps:

[0042] (1) Add urea, cetyltrimethylammonium bromide (CTAB), and cerium nitrate to ethylene glycol, stir to dissolve, add liquid phase titanium source (tetraethyl titanate), and stir to form a homogeneous solution. Then, deionized water was added dropwise to the above system while stirring until a transparent gel was formed.

[0043] (2) Put the above gel into a polytetrafluoroethylene-lined stainless steel autoclave for hydrothermal reaction at 180 °C for 12 h. After the reaction, the precipitated product was washed with deionized water until the pH of the washing solution was neutral, and then dried at 80° C. for more than 10 h. Drying treatment is carried out to obtain the target cerium oxide / titania composite nanomaterial.

[0044] (3) The above-mentioned dried sample was calcined at 400 °C for 2 h to remove residual organic matter to obtain 3D CeO 2 / TiO 2 composite nanomaterials. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com