Sulfur-asphalt based/graphene composite material and preparation method and application thereof

A composite material and graphene technology, applied in the field of electrochemical energy storage, can solve problems such as restricting development, low product added value, and short battery cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

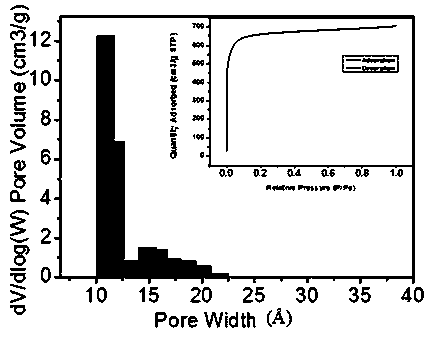

Embodiment 1

[0063] The specific experimental process is as follows: (1) Industrial solid asphalt was vacuum-dried at 120°C for 3 hours, and then 50.0 g of agate balls with a diameter of 1-1.3 cm were put into an agate ball mill jar containing 50 g of treated asphalt, and then The ball mill jar was placed on a planetary ball mill and ball milled at a speed of 650 rpm for 5 hours. Take out the agate ball with tweezers, and dry the solid sample at 70 °C for 48 hours; (2) Mix and impregnate the above-mentioned asphalt powder with KOH for 60 hours at 40 °C, and then The mixed sample was blown and dried for 48 hours at a temperature of 110 degrees Celsius; (3) The obtained solid material was activated in an argon atmosphere at 700 degrees Celsius for 8 hours, and then washed with 10% hydrochloric acid aqueous solution and deionized water to neutrality, Use a polypropylene bag (pore size 20 microns) to separate the solid from the liquid, and dry the resulting solid at 120 degrees Celsius for 6 h...

Embodiment 2

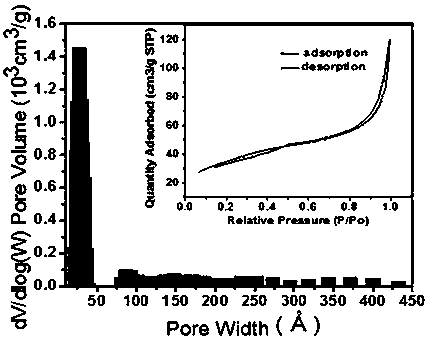

[0066] The specific experimental process is as follows: (1) The industrial solid asphalt was vacuum-dried at 120 degrees Celsius for 3 hours, and then 200g of zirconia balls with a diameter of 3-8mm and 40g of asphalt were sealed in a zirconia ball mill jar under the protection of argon. Then the ball mill jar was placed on a planetary ball mill and ball milled at a speed of 600 rpm for 4 hours. Take out the zirconia ball with tweezers, sieve the milled sample with an ultrasonic vibrating sieve, take a 20-mesh sample and dry it at 100 °C for 24 hours; (2) Mix 20 g of treated pitch with 5 g of graphene and solid 40 g Na 2 CO 3Stir after ultrasonic mixing. The ultrasonic frequency is 20 kHz, the power density is 800w, the time is 8 hours, the temperature is 40 degrees Celsius, and the stirring time is 24 hours. Polystyrene membrane (pore size 2 microns) is used to achieve solid-liquid separation, the solid remains in the bag, and the liquid is thrown out, pressed out, extrude...

Embodiment 3

[0070] The specific experimental process is as follows: (1) Take 100 g of liquid industrial pitch and dissolve it in N-N dimethylformamide, add the surfactant cetyltrimethylammonium chloride during the stirring process, and ultrasonicate for 5 hours at a frequency of 2000 Hz , with a power density of 800 watts, then mechanically stirred for 24 hours, and used a polystyrene membrane (pore size of 5 microns) for solid-liquid separation, and the obtained solid was dried at 120 degrees Celsius for 4 hours; (2) 50 g of the above-mentioned asphalt was mixed with 10 g of nitrogen-doped graphene was mixed, and dissolved in 300 milliliters of 80% by mass ZnCl in aqueous solution for high-speed shear mixing. The time is 2 hours, the temperature is 60 degrees Celsius, and the rotation speed is 2000 rpm. Polypropylene bag (pore size 5 microns) is used for solid-liquid separation. The solid remains in the bag and the liquid is thrown out; (3) The above solid is separated at 800 Activate wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com